LZCORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORRIGATED SHEET 7210701000

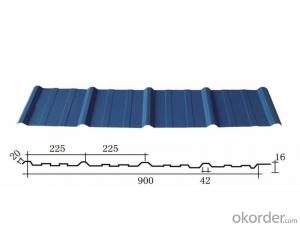

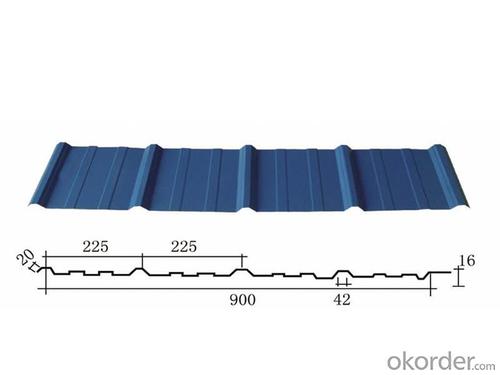

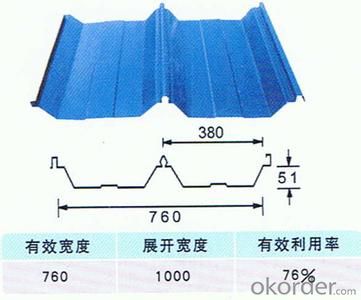

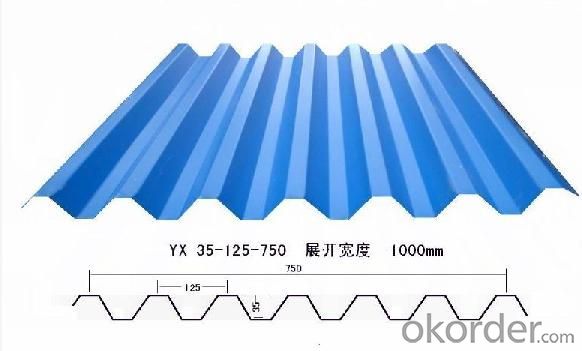

Product Name:corrugated steel roofing sheet

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

In continuous units in cold rolled steel strip, galvanized steel (electro galvanized and hot dip galvanized) as substrate, after surface pretreatment (degreasing and science processing), using the method of roll coating, coated with a layer or multi-layer liquid coating of plate, after baking and cooling income is the coating steel plate. Because the coating can have a variety of colors, on the habits of the coated steel sheet is called color coating steel plate. Because the coating is carried out before the sheet metal forming, in foreign countries which is called pre coating plate.

Color coated steel sheet is an organic coating coating on the steel surface, it has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, easy processing molding, but also allows the user to reduce costs, reduce pollution.

From the United States in 1935 to establish the first continuously coated steel line to begin, color coated steel plate has been widely applied, the current color coated plate varieties, about more than 600 kinds, the advantages of color coated sheet and organic polymer and steel plate of the two, which has good colorability, organic polymer molding, corrosion resistance and decorative, and steel plate with high strength and easy processing, can easily be punching cutting, bending, deep drawing processing. Made this makes organic coated steel sheet products have excellent practical, decorative, workability, durability.

- Q: What are the different profile options available for steel sheets?

- There are several different profile options available for steel sheets, each serving different purposes and offering unique benefits. Some of the most common profile options include: 1. Plain Sheet: This is the simplest and most basic profile option, with a flat surface and no additional features. It is commonly used for general purposes where aesthetics are not a priority. 2. Corrugated Sheet: Corrugated steel sheets have a series of parallel ridges and grooves, creating a wavy pattern. This profile provides extra strength and rigidity, making it ideal for roofing, cladding, and fencing applications. The ridges also enhance water shedding, preventing water accumulation on the surface. 3. Ribbed Sheet: Ribbed steel sheets have a series of raised parallel ridges or ribs running along the length of the sheet. This profile offers improved strength and load-bearing capacity, making it suitable for applications that require structural integrity, such as mezzanine floors, decking, and industrial flooring. 4. Perforated Sheet: Perforated steel sheets have a pattern of holes punched into them, allowing for ventilation, light transmission, and drainage. This profile is commonly used in architectural designs, façades, acoustics, and filtration systems. 5. Tread Plate: Tread plates have a raised pattern of lines or diamonds embossed on the surface. This profile provides extra grip and slip resistance, making it ideal for industrial flooring, stairs, ramps, and walkways. 6. Expanded Metal: Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in a pattern of diamond-shaped openings. This profile offers excellent ventilation, visibility, and security, making it suitable for applications such as grilles, screens, fences, and enclosures. 7. Lipped Sheet: Lipped steel sheets have an edge or lip bent at a 90-degree angle along one or more sides. This profile provides added strength and stiffness, making it commonly used for framing, shelving, and edge protection. These are just a few examples of the different profile options available for steel sheets. The choice of profile depends on the specific requirements of the application, such as strength, durability, aesthetics, and functionality.

- Q: Can steel sheets be used for kitchen appliances?

- Yes, steel sheets can be used for kitchen appliances. Steel is a durable and versatile material that is commonly used in the manufacturing of various kitchen appliances such as refrigerators, ovens, and dishwashers. It offers excellent heat resistance, is easy to clean, and provides a sleek and modern look to the appliances.

- Q: What is the difference between a coated and uncoated stainless steel sheet?

- A coated stainless steel sheet refers to a stainless steel sheet that has been coated with a protective layer or finish, which could be a polymer or another material. This coating serves to enhance the sheet's resistance to corrosion, scratches, and other forms of damage. The coating also provides a decorative or aesthetic appeal, as it can come in different colors or textures. On the other hand, an uncoated stainless steel sheet refers to a stainless steel sheet that does not have any additional protective layer or finish. It is in its natural state, with its inherent properties and characteristics. Uncoated stainless steel sheets are known for their high resistance to corrosion, durability, and strength. They are commonly used in applications where their natural properties are sufficient to withstand the intended environment. The main difference between coated and uncoated stainless steel sheets lies in their protective properties and appearance. Coated stainless steel sheets offer an extra layer of protection against corrosion and damage, making them suitable for environments where there is a higher risk of exposure to harsh conditions or corrosive substances. They also provide a wider range of design options due to their variety of coatings. Uncoated stainless steel sheets, on the other hand, are preferred in applications where the natural properties of stainless steel are sufficient to meet the requirements. They are often used in architectural and structural applications, as well as in industries such as food processing, pharmaceuticals, and medical equipment, where hygiene and durability are essential. In summary, the difference between a coated and uncoated stainless steel sheet lies in the additional protective layer and aesthetic options offered by the coating. Coated stainless steel sheets provide enhanced resistance to corrosion and damage, as well as a wider range of design choices, while uncoated stainless steel sheets rely on their inherent properties for durability and strength. The choice between the two depends on the specific application and the desired balance between protection, aesthetics, and cost.

- Q: Are steel sheets resistant to warping or bending under load?

- Yes, steel sheets are highly resistant to warping or bending under load due to their inherent strength and rigidity.

- Q: Are steel sheets resistant to graffiti?

- Yes, steel sheets are generally resistant to graffiti due to their smooth and non-porous surface, making it difficult for spray paint or other graffiti materials to adhere. Additionally, steel sheets can be easily cleaned or repainted if graffiti does occur.

- Q: Can steel sheets be used for architectural sculptures?

- Yes, steel sheets can be used for architectural sculptures. Steel sheets are a versatile material that can be shaped, cut, and welded into various forms, making them suitable for creating intricate and durable architectural sculptures. They offer strength, stability, and the ability to withstand outdoor conditions, making them a popular choice for many artists and architects.

- Q: Are steel sheets suitable for outdoor sculptures or artwork?

- Yes, steel sheets are suitable for outdoor sculptures or artwork. Steel is a durable and weather-resistant material that can withstand various environmental conditions, making it ideal for outdoor installations. Additionally, steel sheets offer versatility in terms of shape, form, and texture, allowing artists to create unique and long-lasting outdoor sculptures or artwork.

- Q: What is the maximum size available for steel sheets?

- The maximum size available for steel sheets can vary depending on the specific type and grade of steel being used, as well as the manufacturing capabilities of the steel supplier. However, in general, steel sheets can be manufactured in sizes ranging from small sheets measuring a few inches in width and length, to large sheets measuring several feet or even meters in width and length. The maximum size available for steel sheets can also be influenced by the transportation and handling limitations, as larger sheets may be more difficult to transport and maneuver. It is best to consult with a steel supplier to determine the maximum size available for steel sheets that meet your specific requirements.

- Q: Are steel sheets resistant to staining or discoloration?

- Yes, steel sheets are generally resistant to staining or discoloration due to their inherent corrosion-resistant properties.

- Q: Can the steel sheets be used for fencing or security purposes?

- Yes, steel sheets can be effectively used for fencing or security purposes due to their durability and strength. They provide a reliable barrier, making them suitable for securing properties or creating sturdy fences.

Send your message to us

LZCORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords