GI steel sheet GI steel sheet GI steel sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

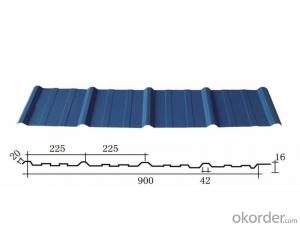

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC | Thickness: | 0.12~1.5mm |

| Place of Origin: |

| Brand Name: |

| Model Number: | 0.12-1.2mm*1250mm or under |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Galvanized |

| Application: | build/appliance/car | Special Use: | Wear Resistant Steel | Width: | 1000mm, 1200mm, 1219mm, 1250mm. |

| Length: | 200~1000m/ton | Base metal: | hot dipped galvanized steel | Coil ID: | 508mm/610mm |

| Feature: | anti-erosion |

Packaging & Delivery

| Packaging Detail: | 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection |

| Delivery Detail: | after payment for 30days |

Specifications

1. Entity factory

2. Galvanization or hot dip

3. (0.12-1.5)*1250mm or under

4.SGCC/JIS/G3302/DX51D

5.A competitive price

Galvanized Steel

| Company | |

| Product | Hot dipped galvanized steel coil |

| Standard | ASTM A653/JIS G3302/GB/T2518-2004 |

| Grade | SGCC,SPCC,DX51D,SGCH |

| Thickness | 0.17mm-0.80mm |

| Width | 914/1000/1219/1220/1250mm or as your requirement |

| Technique | Cold rolled,hot dipped galvanized,chromated,unoiled, TENSION LEVELLERT SKIN PASS |

| Applaication | Structure use,roofing,profile,commercial use,household appliance,industry,etc. |

| Type | Steel coil |

| Zinc coating | 40-180g/m2 |

| Coil weight | 4-8metric tons |

| Coil ID | 508/610mm |

| FOB price | US$700-900/metric ton |

| Port | Qingdao/Tianjin,China |

| MOQ | 25metric tons |

| Supply ability | 17,000metric tons per month or more |

| Payment terms | T/T,L/C |

| Delivery time | Within 20days upon receipt of payment |

| Packing detail | Wrapped by plastic film and waterproof paper,then fastened on wooden pallet.Shipped by 20'GP containers. |

- Q: Can steel sheets be used for elevator flooring or platforms?

- Yes, steel sheets can be used for elevator flooring or platforms. Steel is a durable and strong material that can support the weight and traffic typically experienced in elevators. It is commonly used in the construction of elevator floors and platforms due to its resilience and safety features.

- Q: Can steel sheets be used for solar panel structures?

- Yes, steel sheets can be used for solar panel structures. Steel is a durable and strong material that can provide structural support for solar panels. It is commonly used for mounting frames, racking systems, and other components of solar panel structures due to its ability to withstand various weather conditions and provide stability.

- Q: Are steel sheets vulnerable to UV radiation?

- UV radiation generally does not pose a threat to steel sheets. This is because steel is a highly durable and resilient material that can withstand various environmental factors, including UV radiation. Unlike other materials, steel does not weaken or degrade when exposed to prolonged sunlight or UV rays. In fact, many steel structures, such as buildings, bridges, and outdoor equipment, are specifically designed to endure outdoor conditions and can remain undamaged by UV radiation for many decades. However, it is worth noting that certain types of steel, such as galvanized steel, may offer even greater resistance to UV radiation due to additional protective coatings applied during the manufacturing process. All in all, steel sheets are a dependable option for applications that require protection against UV radiation.

- Q: What is the process of etching or engraving on steel sheets?

- The process of etching or engraving on steel sheets involves using various techniques to create designs or patterns on the surface of the steel. Typically, a design is either etched or engraved onto a protective coating applied on the steel sheet using chemicals, tools, or lasers. The protective coating is then removed, revealing the etched or engraved design on the steel surface. This process is commonly used in industries such as manufacturing, jewelry making, and metal art.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets are known for their exceptional weather resistance properties. Due to their composition and protective coatings, steel sheets are highly resistant to various weather conditions such as rain, snow, and wind. They have the ability to withstand extreme temperatures, both hot and cold, without any significant deterioration or damage. Additionally, steel sheets are also highly resistant to corrosion, making them an ideal choice for outdoor applications and areas with high humidity or saltwater exposure. The weather resistance of steel sheets helps to ensure their longevity and durability, making them a reliable option for various construction and industrial purposes.

- Q: How are steel sheets protected during shipping?

- Steel sheets are protected during shipping through various measures to prevent damage and ensure their safe delivery. One common method of protection is the use of packaging materials such as cardboard or wooden crates. These crates are specifically designed to hold the steel sheets securely in place, minimizing the risk of movement and potential damage during transportation. In addition to packaging, steel sheets may also be covered with a protective coating or wrap to safeguard them from moisture, dust, and other environmental factors. This coating could be a thin layer of oil, wax, or a specialized rust inhibitor that acts as a barrier against corrosion. To further enhance protection, steel sheets may be stacked and secured using strapping or banding materials, ensuring that they remain in place and do not shift during transit. This prevents any potential impact or friction from causing damage to the sheets. Moreover, shipping companies often employ special handling procedures to minimize the risk of damage. This includes using equipment like forklifts or cranes to load and unload the steel sheets carefully, avoiding any rough handling or accidental drops that could lead to denting or bending. Overall, the combination of appropriate packaging, protective coatings, secure strapping, and careful handling ensures that steel sheets are adequately protected during shipping, minimizing the possibility of any damage occurring and ensuring they arrive in optimal condition to their destination.

- Q: How are steel sheets stored and transported?

- Steel sheets are typically stored and transported in stacks or bundles, where they are secured using steel strapping or banding. These bundles are often stored in warehouses or outdoor storage yards, with appropriate spacing and support to prevent damage. When being transported, steel sheets are loaded onto trucks or shipping containers, ensuring they are properly secured and protected from external elements.

- Q: What are the different forms of steel sheets (flat, perforated, expanded, etc.)?

- There are various forms of steel sheets available to meet different applications and requirements. Some of the options include the following: 1. Flat Steel Sheets: With a smooth and flat surface, these sheets find common use in the construction, fabrication, and manufacturing industries. They are versatile, allowing for easy cutting, shaping, and forming into different products. 2. Perforated Steel Sheets: These sheets feature evenly spaced small holes or perforations. They are commonly used for filtration, ventilation, and decorative purposes. Perforated steel sheets provide excellent airflow and visibility while maintaining their structural integrity. 3. Expanded Steel Sheets: These sheets are created by cutting and stretching a flat steel sheet, resulting in a mesh-like pattern. They offer lightweight, sturdy construction and excellent ventilation and drainage. They are often used in applications such as walkways, gratings, fencing, and security. 4. Galvanized Steel Sheets: These sheets are coated with a layer of zinc, which provides exceptional corrosion resistance. Galvanized steel sheets are suitable for outdoor applications where exposure to moisture and harsh weather conditions is a concern. 5. Stainless Steel Sheets: Made from an alloy of steel and chromium, these sheets offer excellent corrosion resistance and high tensile strength. They find common use in the food industry, transportation, medical equipment, and architectural applications. 6. Cold Rolled Steel Sheets: These sheets are produced by rolling steel at room temperature, resulting in a smooth and even surface. Cold-rolled steel sheets offer improved surface finish, dimensional accuracy, and strength. They are commonly used in the automotive, appliances, and furniture industries. 7. Hot Rolled Steel Sheets: These sheets are produced by heating steel above its recrystallization temperature and then rolling it. Hot-rolled steel sheets have a rougher surface and are more malleable compared to cold-rolled sheets. They are commonly used in structural components, construction, and general fabrication. These examples represent just a fraction of the available forms of steel sheets. Each type possesses unique properties and advantages that make them suitable for various applications and industries.

- Q: Can steel sheets be formed into corrugated panels?

- Yes, steel sheets can be formed into corrugated panels.

- Q: Are steel sheets suitable for elevator shafts?

- Indeed, elevator shafts can be suitably constructed using steel sheets. Steel, renowned for its robustness, endurance, and fire-resistant qualities, is extensively utilized in the construction sector. Considering the demands of elevator shafts, which necessitate a material capable of enduring substantial weights, maintaining structural integrity, and meeting safety regulations, steel sheets perfectly meet these prerequisites. Opting for steel sheets grants the flexibility to fabricate them into the desired dimensions and contours, facilitating creative design possibilities. Moreover, steel is effortlessly maintainable and repairable, guaranteeing the prolonged lifespan of the elevator shaft.

Send your message to us

GI steel sheet GI steel sheet GI steel sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords