All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the considerations for using steel sheets in the design of off-road and heavy-duty construction equipment?

There are several key considerations when using steel sheets in the design of off-road and heavy-duty construction equipment. Firstly, the strength and durability of steel make it an ideal material for withstanding the harsh conditions and heavy loads typically encountered in these applications. Steel sheets offer high tensile strength, impact resistance, and structural integrity, ensuring the equipment can withstand rough terrains and challenging environments.

Additionally, the formability and versatility of steel sheets allow for complex shapes and structures to be easily fabricated, enabling designers to optimize the equipment's functionality and performance. This versatility also facilitates customization and adaptation to specific project requirements.

Furthermore, steel sheets can be effectively welded and joined, providing strong and reliable connections between components. This is crucial for ensuring the overall stability and safety of the equipment during operation.

Another consideration is the corrosion resistance of steel sheets. Off-road and heavy-duty construction equipment is often exposed to moisture, chemicals, and other corrosive elements. By selecting appropriate steel grades and implementing protective coatings, designers can enhance the equipment's resistance to rust and corrosion, prolonging its lifespan.

Lastly, the cost-effectiveness of steel sheets is a significant consideration. Steel is widely available and relatively affordable compared to other materials with similar properties. Its durability and long-term performance make it a cost-effective choice for off-road and heavy-duty construction equipment, as it reduces maintenance and replacement costs over time.

Overall, the considerations for using steel sheets in the design of off-road and heavy-duty construction equipment encompass strength, durability, formability, weldability, corrosion resistance, and cost-effectiveness. By carefully evaluating these factors, designers can ensure the equipment meets the demanding requirements of these applications while maximizing performance and longevity.

What is the difference between cold-rolled and hot-rolled steel sheets?

The main difference between cold-rolled and hot-rolled steel sheets lies in the manufacturing process. Cold-rolled steel sheets are produced by cooling down hot-rolled steel and passing it through a series of rollers at room temperature. This process results in a smoother and more precise finish, as well as improved strength and dimensional accuracy. On the other hand, hot-rolled steel sheets are made by heating steel above its recrystallization temperature and then rolling it into the desired shape. This process creates a rougher surface and can lead to larger tolerances and variations in dimensions. Additionally, hot-rolled steel sheets are generally cheaper and easier to produce in large quantities, whereas cold-rolled steel sheets offer higher quality and better suitability for certain applications.

How do you join two steel sheets without welding?

One way to join two steel sheets without welding is by using mechanical fasteners such as bolts, screws, or rivets. These fasteners can be drilled through the sheets and tightened to create a secure connection. Additionally, adhesive bonding can be used to join the steel sheets, where a strong industrial adhesive is applied between the surfaces and allowed to cure, creating a strong bond.

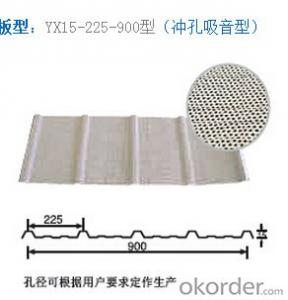

Can steel sheets be used in exterior cladding for buildings?

Yes, steel sheets can be used in exterior cladding for buildings. Steel is a durable and versatile material that offers strength, weather resistance, and design flexibility. It can be used in various forms, such as corrugated or flat sheets, and can provide an attractive and modern look to a building's exterior. Additionally, steel cladding offers benefits such as fire resistance, low maintenance, and long-term durability, making it a popular choice for exterior applications.

Wholesale Steel Sheets from supplier in South Korea

Our team of experts is knowledgeable about the latest industry trends and can provide you with the best solutions for your specific requirements. We offer a wide range of Steel Sheets products, including hot-rolled steel sheets, cold-rolled steel sheets, galvanized steel sheets, and more.

We understand the importance of quality and reliability in the steel industry, which is why we only source our products from trusted manufacturers. Our Steel Sheets are known for their durability, strength, and corrosion resistance, making them suitable for various applications such as construction, automotive, and manufacturing.

In addition to our high-quality products, we also offer competitive prices and flexible payment options to ensure that our customers get the best value for their money. Our dedicated sales team is always available to provide you with accurate quotations and answer any technical questions you may have.

Furthermore, we provide comprehensive technical support to our customers. Our team of engineers is ready to assist you with any design or installation challenges you may face. We can provide guidance on selecting the right Steel Sheets for your project, as well as offer recommendations on the best practices for handling and maintaining the products.

At our company, customer satisfaction is our top priority. We strive to deliver exceptional service and support to our customers in South Korea. Whether you are a small business or a large corporation, we are committed to meeting your needs and exceeding your expectations.

Contact us today to discuss your Steel Sheets requirements and let us help you find the perfect solution for your projects in South Korea.

We understand the importance of quality and reliability in the steel industry, which is why we only source our products from trusted manufacturers. Our Steel Sheets are known for their durability, strength, and corrosion resistance, making them suitable for various applications such as construction, automotive, and manufacturing.

In addition to our high-quality products, we also offer competitive prices and flexible payment options to ensure that our customers get the best value for their money. Our dedicated sales team is always available to provide you with accurate quotations and answer any technical questions you may have.

Furthermore, we provide comprehensive technical support to our customers. Our team of engineers is ready to assist you with any design or installation challenges you may face. We can provide guidance on selecting the right Steel Sheets for your project, as well as offer recommendations on the best practices for handling and maintaining the products.

At our company, customer satisfaction is our top priority. We strive to deliver exceptional service and support to our customers in South Korea. Whether you are a small business or a large corporation, we are committed to meeting your needs and exceeding your expectations.

Contact us today to discuss your Steel Sheets requirements and let us help you find the perfect solution for your projects in South Korea.