All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What challenges and solutions are associated with managing groundwater during deep excavations in earthwork?

Managing groundwater during deep excavations in earthwork poses several challenges. One major challenge is the potential for water infiltration into the excavation, which can lead to instability of the surrounding soil and pose a safety risk. Another challenge is the need to control and lower the groundwater level to create a stable working environment.

To address these challenges, various solutions can be employed. One common solution is the installation of dewatering systems, such as wellpoints or deep wells, to lower the groundwater level and maintain it below the excavation level. These systems help to stabilize the soil and prevent water from infiltrating the excavation.

Another solution is the use of watertight barriers, such as sheet piles or diaphragm walls, to prevent water from seeping into the excavation. These barriers act as a physical barrier between the groundwater and the excavation, ensuring a dry working environment.

Additionally, monitoring and regular assessment of groundwater levels and soil conditions are crucial in managing groundwater during deep excavations. This helps in identifying any potential issues or changes in groundwater levels and allows for necessary adjustments to be made in the dewatering systems or barrier installations.

Overall, effective groundwater management during deep excavations requires a combination of dewatering systems, watertight barriers, and continuous monitoring to ensure a safe and stable working environment.

How is cut and fill balance achieved in earthwork projects, and why is it important?

Cut and fill balance in earthwork projects is achieved by carefully calculating the volume of soil to be cut or removed from the site and the volume of soil to be added, or filled, to achieve the desired grade or elevation. This is done by conducting a topographic survey of the site and using computer-aided design (CAD) software to determine the optimal balance.

Achieving cut and fill balance is important for several reasons. First, it helps to minimize the cost and time associated with earthwork projects. By balancing the amount of excavation and fill required, we can reduce the need for costly and time-consuming processes such as importing or exporting large amounts of soil.

Second, cut and fill balance ensures that the site is properly graded, ensuring the stability and safety of structures to be built on it. By achieving a balanced cut and fill, we can avoid excessive slopes, erosion, or uneven settling that could lead to structural failures or other geotechnical issues.

Finally, achieving cut and fill balance is important for environmental reasons. Excessive excavation or fill can result in the removal or displacement of natural habitats, vegetation, and topsoil. By achieving a balance, we can minimize the impact on the environment and preserve the natural features of the site as much as possible.

In summary, achieving cut and fill balance in earthwork projects is crucial to minimize costs, ensure structural stability, and reduce environmental impact. It requires careful planning, surveying, and design to achieve the optimal balance of excavation and fill, resulting in a successful and sustainable project.

What are the key differences between strip mining and conventional earthwork?

The key differences between strip mining and conventional earthwork lie in their objectives and methods. Strip mining is primarily used for extracting valuable minerals or resources from the earth's surface, often involving the removal of large amounts of soil and rock to access the desired material. On the other hand, conventional earthwork typically refers to excavation and grading activities that shape the land for construction purposes, such as building roads or leveling a site.

In terms of methods, strip mining involves the systematic removal of layers of soil and rock to expose the mineral deposit, often resulting in large open pits or trenches. This process can cause significant environmental impacts, including deforestation, soil erosion, and water pollution. Conversely, conventional earthwork focuses on moving and shaping the earth's surface using heavy machinery like excavators and bulldozers, aiming to create a desired topography while minimizing environmental disruption.

Overall, strip mining is driven by the extraction of valuable resources, while conventional earthwork is focused on preparing land for construction projects. The environmental impacts associated with strip mining are often more severe compared to conventional earthwork, which is typically performed with more care and attention to environmental conservation.

Wholesale Earthwork from supplier in South Korea

With a commitment to excellence, we strive to provide the highest quality Earthwork products to our clients in South Korea. Our sales team is well-equipped to understand your specific needs and offer tailored solutions that meet your project requirements.

In addition to sales, our quotation team ensures that you receive competitive pricing for all our Earthwork products. We understand the importance of cost-efficiency in your projects and work closely with you to provide accurate and timely quotations.

Furthermore, our technical support team is always available to assist you with any queries or concerns you may have regarding our Earthwork products. We have a deep understanding of the local market and regulations, allowing us to provide expert advice and guidance throughout the project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry-leading expertise. This enables us to offer comprehensive Earthwork procurement services, ensuring that you have access to the best products and solutions for your projects in South Korea.

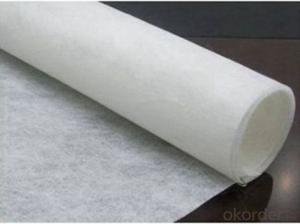

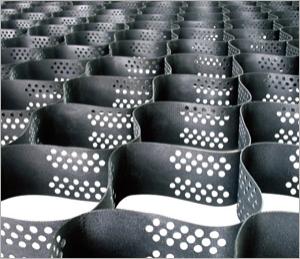

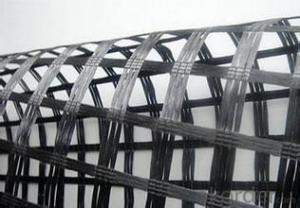

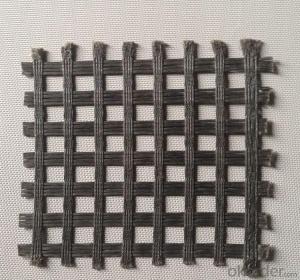

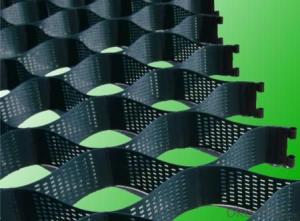

We take pride in our extensive portfolio of Earthwork products, which includes geosynthetics, geomembranes, geotextiles, and geogrids, among others. These products are sourced from trusted manufacturers and are known for their quality, durability, and compliance with international standards.

Our years of experience and market development in South Korea have given us invaluable insights into the local industry. This allows us to provide unparalleled support and guidance, ensuring the success of your Earthwork projects.

In conclusion, as a prominent Earthwork supplier catering to South Korea, we are committed to delivering top-notch sales, quotation, and technical support services. With our comprehensive procurement services, extensive portfolio of Earthwork products, and industry-leading expertise, we are confident in our ability to meet and exceed your expectations.

In addition to sales, our quotation team ensures that you receive competitive pricing for all our Earthwork products. We understand the importance of cost-efficiency in your projects and work closely with you to provide accurate and timely quotations.

Furthermore, our technical support team is always available to assist you with any queries or concerns you may have regarding our Earthwork products. We have a deep understanding of the local market and regulations, allowing us to provide expert advice and guidance throughout the project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry-leading expertise. This enables us to offer comprehensive Earthwork procurement services, ensuring that you have access to the best products and solutions for your projects in South Korea.

We take pride in our extensive portfolio of Earthwork products, which includes geosynthetics, geomembranes, geotextiles, and geogrids, among others. These products are sourced from trusted manufacturers and are known for their quality, durability, and compliance with international standards.

Our years of experience and market development in South Korea have given us invaluable insights into the local industry. This allows us to provide unparalleled support and guidance, ensuring the success of your Earthwork projects.

In conclusion, as a prominent Earthwork supplier catering to South Korea, we are committed to delivering top-notch sales, quotation, and technical support services. With our comprehensive procurement services, extensive portfolio of Earthwork products, and industry-leading expertise, we are confident in our ability to meet and exceed your expectations.