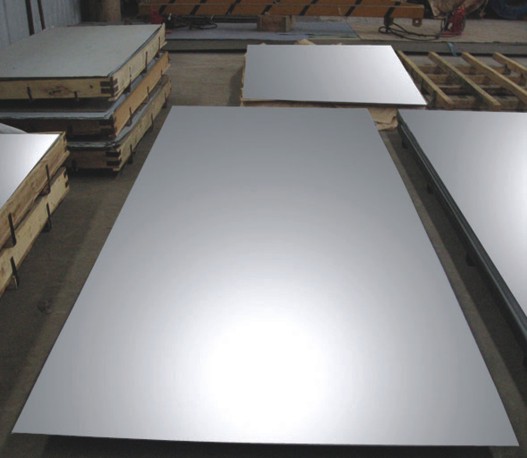

Stainless Steel Sheet 1.0mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction of Stainless Steel Sheet 1.0mmx1220mmx2440mm:

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of Stainless Steel Sheet 1.0mmx1220mmx2440mm: 25 Tons/20FCL.

Grade of Stainless Steel Sheet 1.0mmx1220mmx2440mm: 201, 306, 316 Etc.

Delivery Time of Stainless Steel Sheet 1.0mmx1220mmx2440mm: 20 days Per Container.

Application of Stainless Steel Sheet 1.0mmx1220mmx2440mm:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for Stainless Steel Sheet 1.0mmx1220mmx2440mm are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE Stainless Steel Sheet 1.0mmx1220mmx2440mm samples are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: How do you restore the shine on a stainless steel sheet?

- Achieving a polished appearance for a stainless steel sheet can be accomplished by following a few uncomplicated steps. Initially, it is crucial to ensure the cleanliness of the surface by employing a soft cloth or sponge, as well as a mild detergent mixed with warm water, to wipe away any dirt or debris. Subsequently, the soap residue should be rinsed off and the sheet thoroughly dried. Following this, a minute amount of stainless steel cleaner or polish should be applied to a clean, soft cloth. In a circular motion, gently rub the cleaner onto the stainless steel sheet, paying particular attention to areas that exhibit visible marks or dullness. It is important to adhere to the instructions provided by the manufacturer for the specific cleaner or polish being utilized. After the cleaner has been applied, allow it to remain on the surface for several minutes, permitting it to work its magic. Then, utilizing a fresh section of the cloth, buff the stainless steel sheet by employing circular motions until the shine begins to manifest. This process should be continued until satisfaction with the results is achieved. If a specialized stainless steel cleaner or polish is not available, household items can also be utilized to restore the shine. For instance, a paste can be formed by combining baking soda and water, which can then be applied to the sheet. Gently rub the paste onto the surface using a soft cloth and rinse it off thoroughly. Furthermore, vinegar or lemon juice can be employed to eliminate stains or spots. Applying a small quantity of vinegar or lemon juice to a cloth and rubbing it onto the stainless steel sheet, followed by rinsing and thorough drying, can effectively remove such blemishes. It is imperative to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet before employing it on the entire surface. This will ensure that no damage or discoloration occurs.

- Q: Can stainless steel sheets be used in high-temperature environments?

- Yes, stainless steel sheets can be used in high-temperature environments. Stainless steel is known for its excellent heat resistance properties, making it suitable for various applications in high-temperature environments. The specific grade of stainless steel used and its composition determines its maximum operating temperature. Austenitic stainless steels, such as grades 304 and 316, can withstand temperatures up to 1600°F (870°C) without losing their mechanical strength or corrosion resistance. However, higher alloyed stainless steels, such as grades 309 and 310, are specifically designed to handle even higher temperatures, up to around 2100°F (1150°C). These stainless steel sheets are commonly used in industries like power generation, chemical processing, furnace manufacturing, and aerospace, where exposure to extreme heat is a requirement.

- Q: What is the magnetic permeability of stainless steel sheets?

- The magnetic permeability of stainless steel sheets may vary depending on the specific alloy and processing conditions. Generally, stainless steel is known for its low magnetic permeability, which means it is not a good conductor of magnetic fields. However, certain types of stainless steel, like ferritic stainless steel, have a higher magnetic permeability compared to other grades such as austenitic stainless steel. It's worth mentioning that factors like temperature and the presence of external magnetic fields can also impact the magnetic permeability of stainless steel. Therefore, it is advisable to refer to specific technical data or conduct magnetic permeability testing for precise and detailed information about the magnetic properties of stainless steel sheets.

- Q: Can stainless steel sheets be used in high-temperature applications?

- Indeed, high-temperature applications can utilize stainless steel sheets. Renowned for its superb heat resistance characteristics, stainless steel proves itself adaptable in environments boasting elevated temperatures. Notably, it boasts a formidable melting point, ensuring its durability and structural integrity endure even under extreme conditions. Furthermore, stainless steel showcases commendable oxidation resistance, thwarting scale formation and preserving its surface's sleekness. Consequently, stainless steel sheets rank favorably when considering their widespread employment in diverse high-temperature settings, encompassing heat exchangers, furnaces, boilers, and exhaust systems.

- Q: 304 stainless steel plate price ups and downs affected by what factors?

- That is, inventory relations, supply and demand has been constantly guide prices, and inventory is a good response to the current market supply and demand. Oversupply, stainless steel prices, inventory backlog. Supply falls short of demand, and inventories are very tight as prices rise. If a series of stainless steel prices are too high, then the stainless steel market will appear in this series of alternatives. Substitutes generally have many advantages, such as low prices, cheap materials, superior performance and so on. Therefore, the emergence of substitutes can also cause price fluctuations.

- Q: Advantages and disadvantages of stainless steel

- Stainless steel is the main advantage of corrosion resistance or high temperature, general acid resistant medium, as well as heat resistance, high temperature oxidation (heat resistant skin) of high temperature stainless steel.

- Q: What are the different types of stainless steel sheet edges available?

- There are several types of stainless steel sheet edges available, including mill edge, slit edge, deburred edge, rounded edge, and beveled edge. Each type has its own unique characteristics and is used for specific applications.

- Q: 430 stainless steel plate maximum temperature tolerance is how many degrees?

- 430 stainless steel plate, maximum heat resistance is 900 degrees celsius.

- Q: How do stainless steel sheets compare to other materials, such as aluminum or carbon steel?

- Stainless steel sheets offer distinct advantages when compared to other materials like aluminum or carbon steel. They have superior corrosion resistance, making them ideal for applications in harsh environments or industries like food processing. Stainless steel sheets also possess high heat resistance, strength, and durability, making them suitable for various structural and industrial purposes. While aluminum is lightweight and has good conductivity, it lacks the same level of strength and corrosion resistance. Carbon steel, on the other hand, is strong but more susceptible to corrosion. Overall, stainless steel sheets provide a balance of strength, durability, and corrosion resistance, making them a preferred choice in many industries.

- Q: Are stainless steel sheets suitable for outdoor sculptures or artwork?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or artwork. Stainless steel is known for its durability, corrosion resistance, and ability to withstand harsh weather conditions. It can maintain its appearance and integrity even when exposed to rain, sun, and other environmental factors. Additionally, stainless steel offers a sleek and modern aesthetic, making it a popular choice for outdoor sculptures or artwork.

Send your message to us

Stainless Steel Sheet 1.0mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords