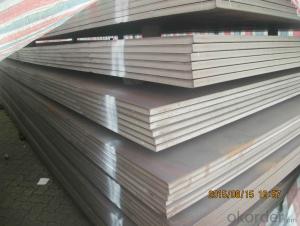

Hot Rolled Steel Plates Made in China WIth Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

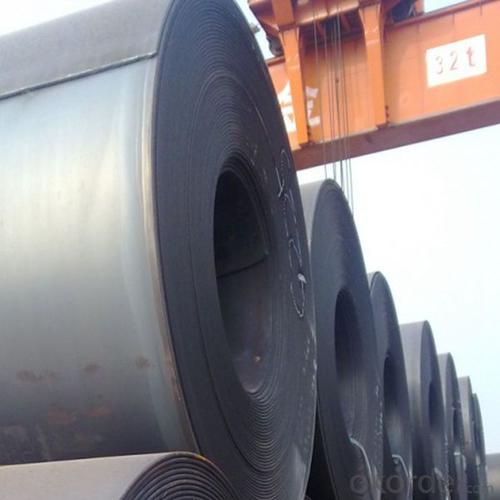

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: How do you prevent scratching on stainless steel sheets during handling and installation?

- To avoid scratching stainless steel sheets while handling and installing them, there are several precautions you can take: 1. Apply protective covering: Prior to handling or installation, it is advisable to apply a protective film or covering on the surface of the stainless steel sheets. This covering acts as a barrier, safeguarding against scratches and scuff marks during transportation and installation. It is important to ensure that the chosen covering is suitable for stainless steel and leaves no residue when removed. 2. Handle with caution: It is crucial to be mindful of how you handle the stainless steel sheets. Avoid dragging or sliding them against rough surfaces or each other, as this can result in scratches. Instead, use appropriate lifting techniques and handle the sheets with clean, dry hands or gloves to minimize the risk of leaving marks. 3. Utilize suitable tools: When working with stainless steel sheets, ensure that you use tools specifically designed for this purpose. Refrain from using tools with rough or abrasive surfaces that could potentially scratch the stainless steel. Opt for tools made from soft materials or those with protective coatings to reduce the chances of surface damage. 4. Keep work areas clean: Before installing stainless steel sheets, it is essential to ensure that the work area is clean and free from any debris or particles that could potentially scratch the surface. Use a clean cloth or soft brush to wipe down the area, removing any dirt, dust, or loose materials that could cause scratches during the installation process. 5. Secure sheets during transportation: If you need to transport stainless steel sheets, it is crucial to secure them properly to prevent any movement or shifting that could lead to scratches. Utilize appropriate packaging materials such as foam inserts, edge protectors, or straps to keep the sheets in place and minimize the risk of damage. By adhering to these preventive measures, you can significantly reduce the likelihood of scratching stainless steel sheets during handling and installation, ensuring a flawless finish and preserving the quality of the material.

- Q: How do stainless steel sheets resist corrosion?

- Stainless steel sheets resist corrosion due to the presence of chromium, which forms a protective layer on the surface of the material. This layer, known as chromium oxide, acts as a barrier against moisture, oxygen, and other corrosive substances, preventing them from reaching the underlying steel and causing corrosion.

- Q: What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q: What's the drill for stainless steel?

- And the feed amount is greater than 0.15mm, so as not to cut the cold work hardening layer as much as possible. The cutting speed is as low as possible to reduce the cutting temperature.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of both size and shape. They can be cut, bent, or shaped according to specific requirements, allowing for a wide range of customization options.

- Q: Can stainless steel sheets be used for elevator handrails?

- Yes, stainless steel sheets can be used for elevator handrails. Stainless steel is a popular choice for handrails due to its durability, corrosion resistance, and aesthetic appeal. It provides a sleek and modern look, making it a suitable material for elevator handrails.

- Q: What are the common methods of cutting stainless steel sheets?

- There are several common methods of cutting stainless steel sheets, each with its own advantages and limitations. Here are a few commonly used methods: 1. Shearing: Shearing involves using a machine with two blades to slice through the stainless steel sheet. This method is suitable for thinner sheets and produces clean, straight cuts. However, it may leave a slight burr on the edge of the cut. 2. Plasma cutting: Plasma cutting is a versatile method that uses a high-temperature plasma arc to melt and blow away the metal. It is effective for cutting stainless steel sheets of various thicknesses and shapes. Plasma cutting provides fast, precise cuts and can handle both straight and curved lines. 3. Laser cutting: Laser cutting uses a focused laser beam to cut through stainless steel sheets. It is highly accurate and produces smooth, precise cuts with minimal distortion. Laser cutting is suitable for both thin and thick sheets, but it can be slower than other methods for thicker materials. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive particles to cut through stainless steel. This method is precise and can handle various thicknesses and shapes. Waterjet cutting is known for its clean edges and the ability to cut without heat-affected zones. However, it may be slower than other methods and can be more expensive. 5. Sawing: Sawing is a traditional method that involves using a saw blade to cut through stainless steel sheets. It is suitable for thicker sheets and can handle both straight and curved cuts. Sawing produces relatively clean cuts but may result in more material waste compared to other methods. These are just a few of the common methods used to cut stainless steel sheets. The choice of method depends on factors such as the thickness of the sheet, desired cut quality, shape complexity, and budget. It is important to consider the specific requirements of the project and consult with professionals to determine the most suitable cutting method.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Yes, stainless steel sheets are highly suitable for food packaging equipment. Stainless steel is a popular choice in the food industry due to its numerous advantageous properties. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. This makes it safe for direct contact with food products. Additionally, stainless steel is resistant to corrosion, rust, and staining, which ensures the durability and longevity of the equipment. It is also easy to clean and sanitize, making it ideal for maintaining high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process. Furthermore, stainless steel has excellent strength and heat resistance properties, allowing it to withstand high temperatures without deforming or compromising its structural integrity. This is particularly important in food packaging equipment where heat sealing or thermal processing is involved. In conclusion, stainless steel sheets are highly suitable for food packaging equipment due to their non-reactive nature, corrosion resistance, ease of cleaning, and high strength. These qualities make stainless steel a reliable and hygienic choice for ensuring the safety and quality of food products during packaging processes.

- Q: What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- Stainless steel sand blasting plates are painted on stainless steel sand blasting plates. Stainless steel sand blasting plate refers to the use of zirconium beads through the mechanical equipment in the stainless steel plate processing, so that the surface of the board presents small beads, grainy sand surface, forming a unique decorative effect. Stainless steel sand blasting decorative board uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities decoration and other stainless steel products.

- Q: Are stainless steel sheets suitable for aerospace applications?

- Stainless steel sheets are well-suited for aerospace applications. This material, known for its versatility and durability, possesses outstanding strength-to-weight ratio, corrosion resistance, and high-temperature resistance. Consequently, it is highly valued within the aerospace industry due to its ability to endure extreme conditions while maintaining structural integrity. Its wide utilization in aircraft structures, engine components, and fuel systems is a testament to its reliability. Furthermore, stainless steel sheets are easily molded, welded, and fabricated, allowing for tailored engineering and precise customization in aerospace applications. Moreover, their resistance to fatigue and erosion ensures their dependability in components that experience constant stress and severe environments. In summary, stainless steel sheets possess the essential qualities necessary to meet the demanding requirements of the aerospace industry, making them an appropriate choice for a variety of applications.

Send your message to us

Hot Rolled Steel Plates Made in China WIth Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords