Hot Rolled Stainless Steel Coils/Sheets Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

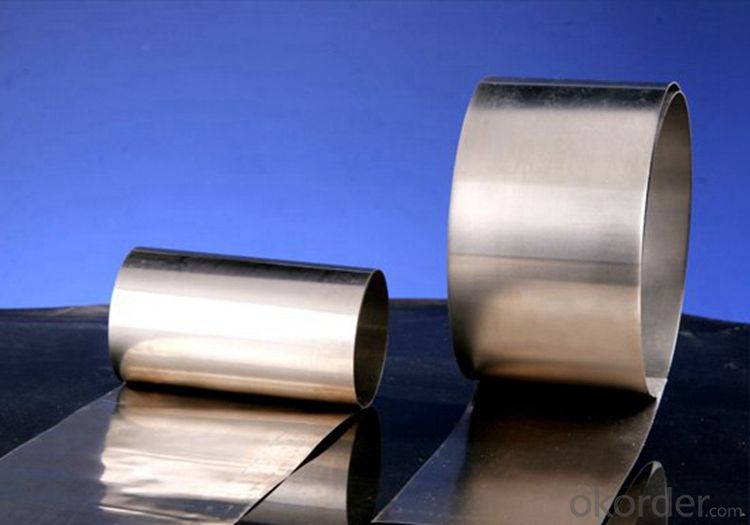

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: What are the different types of etched finishes available for stainless steel sheets?

- Stainless steel sheets come in a range of etched finishes, each with its own unique and distinctive look. Let's explore some of the most common options: 1. Brushed Finish: A popular choice, this etched finish involves using a fine abrasive material to create a smooth and satin-like texture on the surface of the stainless steel sheet. 2. Bead Blasted Finish: For a matte and slightly rough appearance, small glass or ceramic beads are blasted onto the sheet at high pressure, resulting in a non-directional and uniform texture. 3. Mirror Finish: Also known as a No. 8 finish, this etched option gives the stainless steel sheet a flawless and shiny appearance. It involves a series of grinding, buffing, and polishing processes to create a highly reflective and mirror-like surface. 4. Satin Finish: Similar to the brushed finish but with a finer texture, this etched option uses a finer abrasive material during the brushing process, resulting in a soft and elegant appearance. 5. Patterned Finish: This etched finish allows for creative and customizable options, as it involves creating various patterns or designs on the sheet's surface. Techniques such as laser etching, chemical etching, or embossing can be used to achieve this effect. These different etched finishes offer a wide range of aesthetic choices for stainless steel sheets, making them suitable for various architectural, decorative, and industrial applications. The choice of finish depends on the desired appearance, functionality, and intended use of the sheet.

- Q: Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers.

- Q: Can stainless steel sheets be used for electrical applications?

- Certainly, electrical applications can make use of stainless steel sheets. Stainless steel, an alloy comprising chromium, possesses exceptional resistance against corrosion and oxidation. Such resistance proves advantageous in electrical applications that involve exposure to moisture or harsh surroundings. Stainless steel sheets find utility in a range of electrical components, including electrical enclosures, control panels, junction boxes, and electrical connectors. The robustness and durability of stainless steel render it ideal for these applications, ensuring a dependable and enduring solution. Moreover, the non-magnetic properties of stainless steel offer added benefits in specific electrical applications where minimizing magnetic interference is crucial.

- Q: What are the different types of stainless steel sheet thickness tolerances?

- The different types of stainless steel sheet thickness tolerances include standard, tight, and extra tight tolerances. Standard tolerances allow for slight variations in thickness, tight tolerances have lower permissible deviations, and extra tight tolerances have even smaller allowable variations in thickness.

- Q: What are the different types of stainless steel sheet alloys available?

- There are several different types of stainless steel sheet alloys available, each offering unique properties and characteristics. Some of the most common stainless steel sheet alloys include: 1. Austenitic Stainless Steel: This type of stainless steel is the most widely used and versatile. It is non-magnetic and contains high levels of chromium and nickel, offering excellent corrosion resistance and good formability. Austenitic stainless steel alloys include 304 and 316 grades. 2. Ferritic Stainless Steel: Ferritic stainless steel is magnetic and contains high levels of chromium. It has good corrosion resistance and is typically less expensive than austenitic stainless steel. Common ferritic stainless steel alloys include 430 and 446 grades. 3. Martensitic Stainless Steel: Martensitic stainless steel is magnetic and contains high levels of carbon and chromium. It is known for its hardness and strength, making it suitable for applications requiring high wear resistance. Martensitic stainless steel alloys include 410 and 420 grades. 4. Duplex Stainless Steel: Duplex stainless steel is a combination of austenitic and ferritic stainless steels, offering a balance of both their properties. It has increased strength and corrosion resistance compared to austenitic stainless steel. Common duplex stainless steel alloys include 2205 and 2507 grades. 5. Precipitation Hardening Stainless Steel: Precipitation hardening stainless steel alloys are heat treatable and can achieve high strength levels. They contain elements such as copper, aluminum, or titanium, which form precipitates during heat treatment, resulting in increased strength. Common precipitation hardening stainless steel alloys include 17-4PH and 15-5PH grades. It is important to consider the specific requirements of your application when selecting a stainless steel sheet alloy, as each alloy has its own strengths and limitations.

- Q: Lead and stainless steel plate welding together? How do you solder it?

- Lead and stainless steel plate of the two dissimilar metals can be welded together by friction welding or ultrasonic wave can be. Friction welding is a kind of solid phase welding with mechanical energy as energy source. It is caused by mechanical friction between two surfaces of heat to metal connection. The friction welding heat concentrated in the joint surface, so the heat affected zone is narrow. Between the two surfaces to exert pressure, in most cases is increasing pressure at the end of the heating, the hot metal by upsetting combined with general the surface does not melt. Friction welding productivity is relatively high, almost all the forging metal on friction welding principle. Friction welding can also be used for welding dissimilar metals. The workpiece shall be suitable for a circular cross-section with a maximum diameter of 100mm.

- Q: How do I determine the hardness of stainless steel sheets?

- There are various techniques available for determining the hardness of stainless steel sheets. One commonly used method is the Rockwell hardness test, which involves measuring the depth of penetration of an indenter into the material. The Rockwell scale offers different scales for different materials, so it is essential to select the appropriate scale for stainless steel. To conduct the Rockwell hardness test, you will require a Rockwell hardness tester and either a diamond or tungsten carbide indenter. Begin by placing the stainless steel sheet on a stable, flat surface. Next, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. After the load has been applied and released, the hardness value will be displayed on the dial or digital display of the Rockwell hardness tester. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to remember that the Rockwell hardness test provides a relative measurement of hardness and may not accurately reflect the physical properties of the material. Moreover, the hardness of stainless steel can vary depending on factors such as alloy composition, heat treatment, and manufacturing process. Therefore, it is advisable to consult the material's specifications or conduct additional tests to obtain a more accurate and comprehensive understanding of the stainless steel sheet's hardness.

- Q: How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, it is important to clean them regularly using mild soap or detergent and water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Additionally, wipe down the sheets with a soft cloth to remove any fingerprints or smudges. Applying a thin layer of stainless steel cleaner or polish can help maintain the shine and protect against stains. It is also recommended to avoid exposure to harsh chemicals or acidic substances, as they can cause discoloration.

- Q: What is the water absorption rate of stainless steel sheets?

- Stainless steel sheets have a typically very low or negligible rate of water absorption. Renowned for its superb corrosion resistance and impermeability to liquids, including water, stainless steel is extensively acknowledged. Thanks to its distinct composition and surface properties, water absorption and penetration into stainless steel sheets are not easily facilitated. Hence, stainless steel is favored for numerous moisture-sensitive applications, for instance, in the food and beverage sector, medical equipment, and outdoor structures.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Yes, stainless steel sheets are highly suitable for food packaging equipment. Stainless steel is a popular choice in the food industry due to its numerous advantageous properties. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. This makes it safe for direct contact with food products. Additionally, stainless steel is resistant to corrosion, rust, and staining, which ensures the durability and longevity of the equipment. It is also easy to clean and sanitize, making it ideal for maintaining high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process. Furthermore, stainless steel has excellent strength and heat resistance properties, allowing it to withstand high temperatures without deforming or compromising its structural integrity. This is particularly important in food packaging equipment where heat sealing or thermal processing is involved. In conclusion, stainless steel sheets are highly suitable for food packaging equipment due to their non-reactive nature, corrosion resistance, ease of cleaning, and high strength. These qualities make stainless steel a reliable and hygienic choice for ensuring the safety and quality of food products during packaging processes.

Send your message to us

Hot Rolled Stainless Steel Coils/Sheets Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords