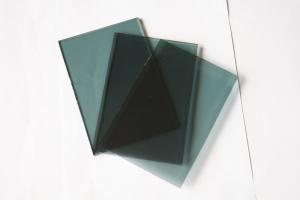

Clear Sheet Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sheet Glass is a kind of ultra thin glass, whose thickness is less than 3mm.

Features of Clear Sheet Glass:

1. good planeness

2. little tolerance on thickness

3. excellent quality

Specifications of Clear Sheet Glass:

Thickness: 2.7mm

Size:

500*700mm; 600*900mm

610*914mm; 1220*914mm

1830*1220mm; 1830*2440mm

customized size

Applications of Clear Sheet Glass:

Sheet Glass is mainly used in picture frames, mirrors, windows, building, arts and crafts, instruments, etc.

- Q: What is the raw material of glass products?

- Ordinary glass raw materials are soda ash (sodium carbonate), limestone (calcium carbonate) and silica, after a high temperature reaction, the products are mainly sodium silicate, calcium silicate and silica

- Q: How can glass frosting be formulated? What raw materials do you use?

- 1. Prepare glass cleaning solution:Pour 6 parts of tap water and 1 parts of hydrofluoric acid into plastic container. Stir well.2. Glass cleaning:The glass will be placed on the cleaning shelf, then use the sponge coke on the glass solution, wipe evenly on the surface of the glass, the glass surface cleaning liquid to stay in 5-10 seconds, and then rinse with water glass, (to ensure the glass surface without stains, so as not to affect the frosting effect.)Please note: in the glass side 3-5 seconds before frosting, the water drained, they bring too much water in the frosting liquid, effect of frosting liquid.

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- The crystal silicon component adopts super white embossed toughened glass; the thin film battery component adopts ultra white float glass (after coating) and ordinary toughened glass.The panel and battery are bonded with EVA film.

- Q: Method for cutting thick glass

- Some glass processing before processing, to the original piece of glass polishing, cutting, edge grinding, drilling, washing and drying process, such as tempered glass, laminated glass etc.; there are some glass processing technology, processing after washing and drying, and then according to the use requirements of cutting, grinding, grinding and polishing drilling and washing as final products, such as glass mirror; in addition to the art glass, such as painting, printmaking, relief, need specific processing technology, these are for cold working glass. The cold processing of glass is to process glass products into the required process by means of a series of processing methods at normal temperature.

- Q: What materials do we need to make glass septic tanks?

- 9., the product covers only 60 ~ 80% of the brick and concrete septic tank, which saves land and improves the flexibility of site selection.10., the comprehensive cost is low, and the overall cost is more economical compared with the brick and concrete septic tank.

- Q: What's the price of 0.85mm thick plexiglass, please?

- Domestic cheapest, about 400 or so, but the thickness is not enough, the material is poor

- Q: What is the raw material of glass? How is it converted to glass?

- Formed by converting molten glass to a solid product of a fixed shape. The process must take place within a certain temperature range. This is a cooling process. The glass is first converted from a viscous liquid to a plastic state, and then to a brittle solid. The forming method can be divided into two categories: manual forming and mechanical forming.

- Q: Which brand of thermos cup is safe, double glass is not really glass, there is no other add, affect health?

- Insulation cup is generally made of ceramic or stainless steel containers with vacuum layer made of water, the top cover, seal, vacuum insulation layer can make the liquid inside the slow cooling, in order to achieve the purpose of preservation.

- Q: What are the raw materials of water glass?

- The wet production of quartzite powder and caustic soda as raw materials in autoclave, 2 - 3 atmospheric pressure steam reaction, generating liquid water glass.

- Q: How to choose floor tiles?

- Vitreous tile belongs to all ceramic product. Its abrasion resistance and flexural strength are very high, the water absorption rate (tile water absorption rate is less than 1 per thousand). Before the tiles mainly used for flooring, tiles, as a wall material is mainly used for high-grade Gaestgiveriet Hotel, office space, but now, with the living standard and the improvement of consumption level, the home use tiles for the kitchen wall materials are more and more family.

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1993 |

| Annual Output Value | US$ 10 Million - US$ 50 Million |

| Main Markets | North America; Europe; Australia; Japan; South East Asia; Middle East; Hong Kong; Macao |

| Company Certifications | ISO 9001:2000;ISO14001:2004;OHSAS 18001 system;3C safety Certificate;SGCC (USA);CE (EU);UL (USA) |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Clear Sheet Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords