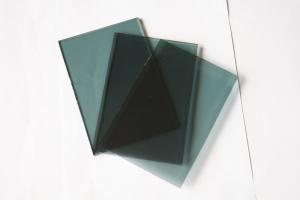

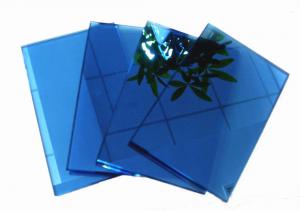

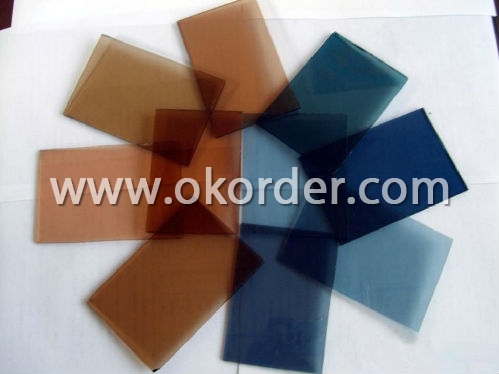

Colored Sheet Glass

- Loading Port:

- Shenzhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 5000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sheet Glass is a kind of ultra thin glass, whose thickness is less than 3mm.

Features of Colored Sheet Glass:

1. good planeness

2. little tolerance on thickness

3. excellent quality

Specifications of Colored Sheet Glass:

Thickness: 2.7mm

Size:

500*700mm; 600*900mm

610*914mm; 1220*914mm

1830*1220mm; 1830*2440mm

customized size

Applications of Colored Sheet Glass:

Sheet Glass is mainly used in picture frames, mirrors, windows, building, arts and crafts, instruments, etc.

- Q: What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q: The main chemical constituents of ordinary glass

- Glass is a silicate product that we can see every dayThe window glass is the most common glass, the glass is called ordinary glass. Manufacture of ordinary glass raw material is sodium carbonate, limestone and quartz. The production, the raw materials are crushed and mixed in proper ratio, add heat strengthened glass kiln. Raw material melting happened after the complex physical and chemical changes. Which is the main reaction:Na2CO3SiO2 Na2SiO3CO2 hav'eCaCO3SiO2 CaSiO3CO2 hav'e

- Q: There are several appearances of the quality defects of ordinary flat glass

- If molten glass contains gas, it forms bubbles when it is formed. Bubbles mainly affect the transmittance of glass, reduce the mechanical properties of glass, but also affect people's vision, resulting in deformation of the biological image, the main reason is that the purity of raw materials is not enough.

- Q: Who has information about power plants chimneys, water glass, acid resistant concrete?

- Acid resistant coarse aggregate: commonly used coarse aggregate are quartzite, Xuan Wuyan, granite, andesite and other made of crushed stones and acid bricks. Quality requirements: acid resistance is not less than 95%; water content is not greater than 0.5%; water absorption rate is not more than 1.5%; 3, not allowed to contain soil. The maximum particle size shall not exceed 1 / 4 of the minimum size of the structure and the net distance between the steel bars 3 / 4, and shall not exceed 25mm for the floor (platform surface) of the building, and less than 213 of the surface thickness.

- Q: What material is the automobile glass made of?

- General automotive glass by silicon glass, the main components of silica content more than 70%, the rest by sodium oxide, calcium oxide, magnesium and other components, made by the float process.. The glass is then further processed into tempered glass (TSG) or laminated glass (LSG).

- Q: What are the Department of mobile phone lens?

- Well, yes, coating is coated, but not what you said, the film, this forgot to say, but generally speaking, is this, in fact, is not very complicated process, as long as there is equipment, it is easy to handle!

- Q: How to choose floor tiles?

- The tiles (or tiles) is the use of earth embryo (or earth embryo to add some ore powder) after high temperature and high pressure one-time firing, using the surface and bottom of embryo material basically identical (except for the special process such as tiles, tiles in the new fill glaze series).

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- The cooling process of tempered glass is the glass internal pressure generated quickly and uniformly high stress and uniform DB toughened glass broken small particles (tempered glass inner stress is greater than or equal to 90 kg / cm2)

- Q: Samsung LCD panel information

- The power supply needs to look at the output power, the output voltage, such as the 26 inch and 32 inch power supply on the market. Other sizes of LCD, or need to consult manufacturers of power supply, specific parameters

- Q: What kind of film is toughened glass film?

- How to identify good protective film for toughened glass:1., bad exhaust surface residual bubble phenomenon;2., toughened glass can not stick around the corner, bubble phenomenon;3., toughened glass and mobile phone adhesion, easy to fall off phenomenon;4., toughened glass is too thick, affecting transmittance, and thickening of mobile phone thickness;5., toughened glass sticking glue is too thick, affect the mobile phone display transmittance;6. toughened glass is pasted on the mobile phone, and the surface of the mobile phone has a watermark phenomenon.7., toughened glass film is also straight edge and arc edge, arc edge relative to the more rounded, not easy to hurt hand

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1993 |

| Annual Output Value | US$ 10 Million - US$ 50 Million |

| Main Markets | North America; Europe; Australia; Japan; South East Asia; Middle East; Hong Kong; Macao |

| Company Certifications | ISO 9001:2000;ISO14001:2004;OHSAS 18001 system;3C safety Certificate;SGCC (USA);CE (EU);UL (USA) |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Colored Sheet Glass

- Loading Port:

- Shenzhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 5000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords