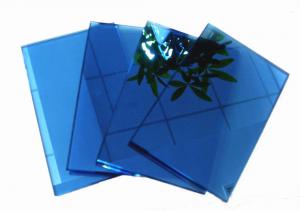

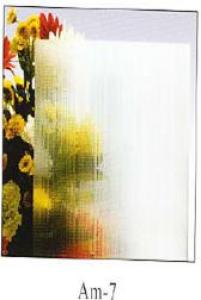

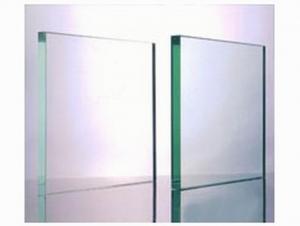

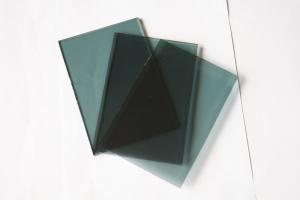

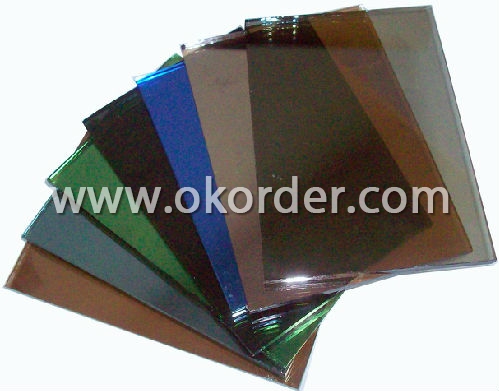

Colored Heat Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Heat-Reflective Coating Glass, also called Solar Control Coating Glass, is a kind of coated glass which has a specific coating deposited by online CVD (Chemical Vapor Deposition) or offline PVD (Physical Vapor Deposition), making the optical performances of the glass change and producing the required reflective color.

Features of Colored Heat Reflective Coated Glass:

1. Effectively limit the incident amount/incidence of the solar radiation with obvious shading effect.

2. Have a good view-obscured function for indoor objects and building components.

3. Save energy and reduce the running expenses of air conditioners.

4. Have a good decorative effect for the external walls of buildings.

5. Have a fine view-shielding function for indoor objects and construction components.

6. Designed for single use or composite use into coated laminated glass, coated tempered glass, coated insulating glass or other coated composite glass.

Specifications of Colored Heat Reflective Coated Glass:

Thickness: 3mm;4mm;5mm;5.5mm;6mm;8mm;10mm;12mm;15mm;19mm

Color: Dark Grey,Euro Grey,Ford Blue,Dark Blue,Ocean Blue,Pink, Clear,Dark Green, French Green,Bronze,etc.

Size:

2440*3660mm

2400*3300mm

2100*3300

customized size

Applications of Colored Heat Reflective Coated Glass:

Heat-Reflective Coating Glass is mainly used for curtain walls.

- Q: What kind of material is glass made of?

- We know that solid materials can be divided into two categories: organic materials and inorganic materials. Organic materials are wood, plastic, plexiglass, cotton, wool, nylon and so on. Inorganic materials can be divided into three categories: single crystal, polycrystal and glass according to the structure. A single crystal has regular shapes and strict rules, such as the ruby is an alumina single crystal, the crystal is a silica single crystal, and the diamond is a single crystal of carbon. Polycrystal is a collection of large amounts of small single crystals, and all kinds of ceramics and metals are polycrystalline materials. Glass is a noncrystalline solid obtained by melting, cooling, and curing. Its structure has certain rules (short-range order) in the atomic and molecular range, but there is no rule (long-range disorder) in the macroscopic range. It can be made into various shapes by moulds.

- Q: Ask the glass making processWhat kind of material is the glass made of? What material is good?

- The main raw materials of glass production with glass forming body, glass and other glass intermediate adjustment, as the auxiliary material. The main raw materials, intermediate oxide and oxide to network oxides into the glass forming network; auxiliary materials including clarifying agent, fluxing agent, emulsifying agent, coloring agent, bleaching agent, oxidant and reductant.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Curtain walls shall be tested for raw materials and field inspection shall be carried out at the construction site. Including pullout test, water resistance test, etc., in details, you just need to read the data form

- Q: Glass factory raw materials specific to do?

- Glass is formed by melting sand with other chemicals (the main ingredients are: soda ash, limestone, quartz). A continuous network structure is formed during melting, and the silicate like non-metallic material is gradually increased and hardened in the process of cooling. The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and toughened glass made by special methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q: There are several appearances of the quality defects of ordinary flat glass

- The wave bar, also called the water line, is the most vulnerable and the most serious defect in the appearance defects of glass. It can cause optical distortion of glass and cause visual fatigue or visual illusion of the observer. There are many reasons for the wave reinforcement, mainly due to the backward production process and chemical composition and excessive impurity content.

- Q: What material does PCB have?

- The surface of the substrate is covered with a layer of high conductivity, good welding of pure copper foil, commonly used thickness of 35 ~ 50 / Ma; copper foil covered in copper clad laminate substrate side called single copper, copper clad laminate substrate on both sides covered with copper foil called double-sided copper clad laminate; copper foil can securely covered on the substrate. The adhesive to complete. Commonly used CCL thickness of 1.0mm, 1.5mm and 2.0mm three.

- Q: The practice of acid corrosion in tank

- Excellent technical performance, it can meet the corrosion protection requirements in the corrosive environment. Technical indexes are formulated for different coating varieties and matching. Such as chemical resistance medium, salt water resistance, salt fog resistance, heat and humidity resistance, oil resistance, mildew resistance, atmospheric aging, etc.. In addition, heavy duty coating has good adhesion to metal substrate. The coating has good physical and mechanical properties, such as low shrinkage, proper hardness, toughness, wear resistance and temperature resistance.

- Q: What is the raw material of glass fiber reinforced plastics and what is the matching ratio?

- The surface felt contains 90% glue, short cut felt is between 60-70%, square cloth 50., compound felt cloth 55%. Specific depends on the technical level of operators. Hope to be of help to you.

- Q: Will toughened glass break naturally?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: What's the difference between crystal and ordinary glass?

- Feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be. Ordinary glass weight is more self-evident.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Asia; Oceania; Mid East; Eastern Europe; North America; South America; Africa; |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 80% |

| No.of Employees in Trade Department | Above 1000 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Colored Heat Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords