Anti-Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

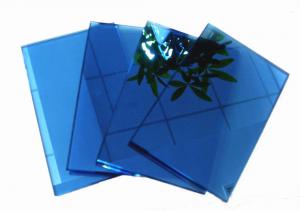

Anti-Reflective Coating Glass, short as AR Glass, is deposited by the hot-dip/immersion plating/dipplating process with anti-reflective coatings on both sides of the glass, making the light transmittance above 98% and reducing largely the reflectivity on the surface of glass compared with the original glass.

Features of Anti-Reflective Coated Glass:

1. Reduce the reflected images, it looks like no glass, greatly enhancing the visual clarity.

2. Make the items true to nature and the colors more beautiful.

3. Further processing (to be tempered, insulated, laminated, etc.) of it is the same as the original glass.

Specifications of Anti-Reflective Coated Glass:

Thickness: 3-12mm (with±0.2mmtolerance)

Max size: 5000*3300mm (with±1mmtolerance)

Applications of Anti-Reflective Coated Glass:

Anti-Reflective Coating Glass is mainly used as flat display panels such as LCD, PDP, outdoor display screen, laptop display and mobile phone display and other electronic display products which need high transmittance and low reflectivity.

AR Glass can also be widely used as building glass, showcase display glass or shopwindow display glass, improving the visual effect significantly.

- Q: Water glass, ceramics, ordinary cement, quartz glass, what are these chemicals?

- Water glass chemical formula is Na2SiO3.9H2O, usually quartz and caustic soda (NaOH) wet production, or with quartz and soda ash (Na2CO3) dry production, both need high temperature.

- Q: What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- First of all, you know what zircon sand is[g o], also known as zirconium sand zircon sand, zircon, is a kind of zirconium silicate (ZrSiO4) as the main mineral composition. Zircon sand pure colorless transparent crystal, often because of quantity and species of different origin and different impurities dyed yellow, orange, red and brown color, crystal structure belongs to tetragonal, a square pyramidal column, the proportion of 4.6 to 4.71, the proportion of the variation with composition and sometimes altered state with zirconium stone incomplete cleavage, uniform Mohs hardness of 7 to 8, the refractive index of 1.93 to 2.01, with the melting point of impurities in different 2190~2420 DEG C wave. The main chemical composition is ZrO2, SiO2, and a small amount of impurities such as Fe2O3, CaO, AI2O3 and so on. The theoretical composition of zircon sand is ZrO2:67.1%; SiO2:32.9%. It is the only compound in the ZrO2-SiO2 system. But natural zircon sand contains only about 57~66%ZrO2.

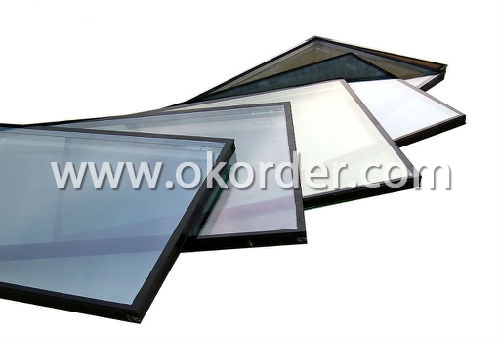

- Q: I want to ask, if the home is already hollow glass, that still need to foil it?

- Insulating glass insulation effect is very good, but insulation, UV effect is not good. If a glass film is attached to the inner glass, the heat insulation effect is more marked, and the harmful ultraviolet ray can be effectively separated from the 99%, and the glass can be prevented from splashing after breaking.

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- The main raw materials for making glass. Generally the sand containing silicon, but in general how much silicon content to differentiate the varieties and quality of silica sand, silica sand with particle size, particle size distribution, particle size distribution is generally good, good quality.

- Q: Acrylic plexiglass rod can be used in what way?

- Plexiglass sticks, which cheap plexiglass bonding is an important process, to enhance product quality and taste, affected by two aspects, one is adhesive; two is adhesive skills.

- Q: What's the raw material for organic glass fiber reinforced plastic? Thank you.

- Fiber reinforced epoxy resin composites are made from resins (unsaturated polyester resin, alkenyl ester resin, epoxy resin, phenolic resin, etc.) Fiber (glass fiber, carbon fiber, aramid fiber, etc.) Made by special process

- Q: How is glass made? What is its raw material?

- Glass is formed by the melting of sand with other chemicals. Glass raw materials for natural ore, the ore will be crushed first, processed into powder, according to the type of glass, according to the formula made of ingredients, into the glass furnace for melting, forming glass liquid. The glass passes through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q: What material is the automobile glass made of?

- The area of toughened glass is a new type of toughened glass, it through special treatment, can impact rupture, crack the glass can still maintain a certain clarity, ensure the driver's field of vision is not affected. At present, the front windshield of the car is mainly made of laminated tempered glass and sandwich area toughened glass, and it can bear strong impact force.

- Q: What kind of glass is smoked glass?

- * clarifierIn the process of making glass, some bubbles will appear. Reducing the bubbles is the use of fining agents, mainly arsenic trioxide, antimony oxide and nitrating salt

- Q: Is the price of glass raw material the biggest proportion of quartz?

- The price of raw materials is the largest proportion of quartz sand.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Anti-Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords