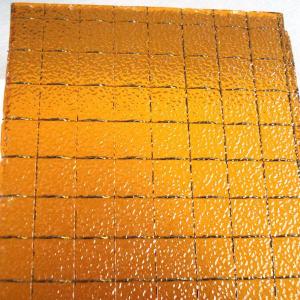

Fire-resistant Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire-resistant Glass is produced adopting new technology. After test analysis, the property of it can be compared with foreign products. What’s more, the processing technology and the product performance take the lead at home in China. It includes wired glass.

Features:

1、Good optical property: the transmittance is the same as float glass.

2、High strength: its strength is 6-12 times the strength of common float glass, it belongs to a kind of safety glass.

3、It can be incorporated into insulating glass with the functions of energy saving, sound insulation and heat insulation. It can also be used to process coating glass with the effect of heat reflection and artistic beauty.

Specifications:

Thickness: 3-19mm

Size:

3660*2440mm

300*300mm

customized size

Applications:

Fire-resistant Glass is mainly used in construction such as curtain walls, doors and windows, partitions, etc.

- Q: What kind of material is glass made of?

- 1. isotropic particles of glass are arranged irregularly in general, but are statistically uniform, so that their physical and chemical properties are the same in any direction. The crystal is anisotropic. Examples: resistivity, thermal conductivity, transmissivity, refractive index, etc..2. there is no fixed melting point. Glass changes from solid to liquid and varies gradually over a range of temperatures. The crystal is determined by melting point, for example, (water ice crystals) in C melt 0 Eve joy. This property of glass makes it possible to be shaped by blowing, pulling, pressing, and other methods.3. tunability of composition and properties. The properties of the glass may vary continuously and gradually within a certain range with their properties. The crystal has a fixed component and a definite performance. In this way, we can adjust the composition of the glass, so that its performance meets the requirements of the use.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Spray glaze workshop generally volatile material is relatively small, so, as long as a good protection, do not spray out of the glaze and lungs can be. Ceramic factory occupational disease is mainly pneumoconiosis, but now most of the ceramic dust prevention in this area is much better than before.

- Q: What material is made of bullet proof glass?

- Bulletproof glass is made of glass (or organic glass) of a composite material and the quality of engineering plastics through special processing is obtained, it is usually transparent material, usually including polycarbonate layer on glass layer.

- Q: Is the production of glass materials as thin as possible? Why?

- Superfine powder in water, stirring, mixing will form a group, how big a mass is equivalent to how much a grain of sand, that is not melting, and eventually in the glass liquid to leave stones, become impurities.

- Q: Is the balance pad the raw material in the motor?

- Commonly used materials: 1 steel motor is divided into two major categories of carbon steel and alloy steel, cast iron can be divided into pig iron for steelmaking, casting iron and iron alloy; the organic material acetal, polyester, polyurethane, polyester imide resin and inorganic material such as glass Lisi etc.; the conductor material: copper, aluminum, copper, Aluminum Alloy silver; the insulation material: glass fiber, PVC, non vulcanized rubber or plastic mixture; the gas insulation material: nitrogen, hydrogen, carbon dioxide, six sulfur hexafluoride; insulating materials such as: liquid oil, transformer oil, switch capacitor oil, cable oil, silicone oil, synthetic oil etc.;, solid insulating materials: such as insulation paint, resin and rubber; impregnated fiber products; laminated material; plastics; mica products; 8 film, adhesive tape and composite materials; thermosetting plastics and thermoplastic adhesive.

- Q: The preparation process of glass and the basic material and the function of raw materials

- Silica sand, quartz sand or sandstone with SiO2 framework structure for glass, glass forming;The role of soda to help melting sand;

- Q: Medium temperature glass flake clay products

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale, which is made of c- glass, has excellent chemical durability.

- Q: What are the materials for car windshields? Is there anything different than ordinary glass?

- Area of toughened glass is a new type of toughened glass, it through special treatment, can impact rupture, crack the glass can still maintain a certain clarity, ensure the driver's field of vision is not affected, has been widely used in the front windshield of the car, but with the demand for vehicle safety and the car environment continues to improve, with the safety performance of laminated glass with good heat insulation and sound insulation performance has gradually become the mainstream of the front windshield.

- Q: What's the difference between plexiglass PS boards and toughened glass? What's the difference between them?

- Suggest that you use semi tempered glass for bathroom glass, do not use non tempered, and the other two are not high prices, that is, shock resistance, heat resistance is not good, very crispThere is this, now you can choose several materials made of transparent or translucent, (the simplest is to take a rub, ha ha)

- Q: As the raw material for glass wool is what

- Collectively, the fibrous silicate glass wool can be split into thin and flexible fiber and available.Glass wool has been used for thousands of years of history.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2008 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | Northern Europe, Africa |

| Company Certifications | Certificate for China Compulsory Product Certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Fire-resistant Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords