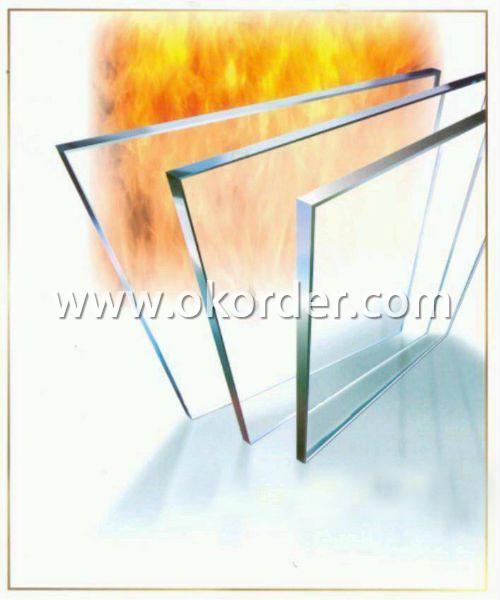

Fire-rated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire-rated Glass is produced adopting new technology. After test analysis, the property of it can be compared with foreign products. What’s more, the processing technology and the product performance take the lead at home in China. It includes wired glass.

Features of Fire-rated Glass:

1、Good optical property: the transmittance is the same as float glass.

2、High strength: its strength is 6-12 times the strength of common float glass, it belongs to a kind of safety glass.

3、It can be incorporated into insulating glass with the functions of energy saving, sound insulation and heat insulation. It can also be used to process coating glass with the effect of heat reflection and artistic beauty.

Specifications of Fire-rated Glass:

Thickness: 3-19mm

Size:

3660*2440mm

300*300mm

customized size

Applications of Fire-rated Glass:

Fire-resistant Glass is mainly used in construction such as curtain walls, doors and windows, partitions, etc.

- Q:What kind of raw materials should be used in making FRP?

- The raw material of glass fiber reinforced plastic is divided into two kinds: reinforced material and base materialThe reinforced material of glass fiber reinforced plastic is composed of glass fiber and its fabric. It is the main load-bearing component material of glass fiber reinforced plastics, and has a direct impact on the strength and stiffness of FRP

- Q:What are the chemicals in glass?

- (some of these ingredients are repeated, and the content of the active ingredients should be carefully calculated when firing the glass) In addition, there are some trace elements, such as metal oxides, used for colored glass, shielding electromagnetic, optical glass and so on. Some other types of special glass materials account for a large proportion of raw materials, and may even contain quartz sand.

- Q:What does GF30 represent in plastic PP GF30?

- (PP) polypropylenePP-GF30 glass fiber reinforced polypropylene content of glass fiber 30%

- Q:What's the name of the transparent plastic board in the market?

- Acrylic is a transliteration word, English is ACRYLIC. It is a chemical material. Chemistry called "PMMA" is a polyacrylate, commonly known as "after the special treatment of plexiglass", in the application industry, acrylic raw materials in general in the form of particles, plates, pipes and other forms.

- Q:A fireproof material is? Except glass wool, rock wool? Please tell me what is the raw material of these materials is?

- Application of phenolic insulation board: the polystyrene foam and polyurethane foam are flammable, no high temperature in some industries in developed countries are restricting the use of the fire department, the fire place of strict requirements, government departments have been expressly provided only with phenolic insulation board. Therefore, phenolic foam is more suitable for high performance materials demanding conditions of use, has good prospects for development. Such as steel structure workshop, large industrial plants, activity room, cold storage, clean workshop, building storey, temporary housing, gymnasium, supermarket and other needs of fire insulation requirements of buildings.

- Q:How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- To have good quality, if the quality of other yarn nets, there may be broken.

- Q:The main reasons for failure of air glass are outlined

- The requirements of the desiccant performance must have low initial adsorption capacity, easy production and operation, while the remaining strong adsorption capacity, ensure the sealing hollow glass has more adsorption capacity and only adsorption, water molecules with wear strength, usually choose 3A molecular sieve as a special adsorption of hollow glass as for the special agent, contain volatile sealant, special ability requirements of desiccant adsorption of organic molecules, the general choice of 13X molecular sieve, molecular adsorption as water and adsorption of organic compounds by sieve. The desiccant absorption capacity of the water vapor as the desiccant temperature varies, different desiccant absorbs water vapor in a given number of different temperature conditions, depending on the hollow glass cavity obtained rate of water vapor, water vapor growth rate is a function of several factors

- Q:What is the density of glass flake cement?

- Glass flake is an important raw material for producing heavy anti-corrosion coatings, pearlescent pigments and plastic products indispensable, used in anti-corrosion field, can significantly improve the anticorrosive performance of the coatings, prolong the service life of the object; used in the manufacture of glass flake pearlescent pigment, pearlescent pigment luster far better than natural mica, synthetic mica pearlescent pigment production, and has antiseptic and anti ultraviolet function; used in plastics industry, plastic products can increase the strength, prevent thermoplastic plastic precision parts made of thermal deformation, improve the stability of space.

- Q:Long plastic soft glass is a food grade raw materials?

- No, this is the PVC material processing process, there will be plasticizers, etc., although non-toxic, harmless, but the food grade standards or worse.

- Q:What is acrylic material?

- Acrylic production process;Acrylic sheet according to the production process can be divided into casting and extrusion, better than the properties of casting sheet extrusion, the price is expensive, the plate casting is mainly used for carving, decoration, arts and crafts, extrusion type is usually used for advertising signs, light boxes and other production.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 1994 |

| Annual Output Value | |

| Main Markets | Japan; Singapore; Southeast Asia |

| Company Certifications | ISO9001;ISO14001;OHSAS18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shantou; Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 54000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fire-rated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords