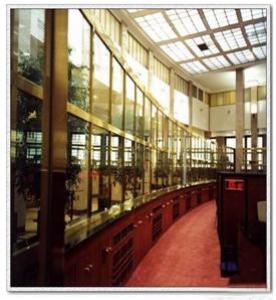

Fire-resistant Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire-resistant Glass is produced adopting new technology. After test analysis, the property of it can be compared with foreign products. What’s more, the processing technology and the product performance take the lead at home in China. It includes wired glass.

Features:

1、Good optical property: the transmittance is the same as float glass.

2、High strength: its strength is 6-12 times the strength of common float glass, it belongs to a kind of safety glass.

3、It can be incorporated into insulating glass with the functions of energy saving, sound insulation and heat insulation. It can also be used to process coating glass with the effect of heat reflection and artistic beauty.

Specifications:

Thickness: 3-19mm

Size:

3660*2440mm

300*300mm

customized size

Applications:

Fire-resistant Glass is mainly used in construction such as curtain walls, doors and windows, partitions, etc.

- Q: How is the glass made?

- The shape of each vessel is irregular. It is shining like a holy lotus under the light. It was introduced that the vessel was blown through a wooden mold. In the 30s of the last century, Artaud also successfully designed many glassware, this free form of utensils is still in production, has become one of Artaud's masterpiece.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Do material testing (including stone moisture content, strength, steel and aluminum, chemical anchor pullout test, compatibility test of sealant, epoxy resin structural adhesive test), four test (water tightness, air tightness, wind pressure, plane deformation etc.)

- Q: What material does PCB have?

- There are many kinds of copper clad laminates. According to different material can be divided into paper substrate, glass cloth substrate and synthetic fiber board; according to the different binder resin is divided into phenolic, epoxy, polyester and polytetrafluoroethylene; use can be divided into general and special type.

- Q: What kind of material is the glass made of?

- The glass is made of glass and the glass is made of silicon dioxide.

- Q: How to choose floor tiles?

- The tiles (or tiles) is the use of earth embryo (or earth embryo to add some ore powder) after high temperature and high pressure one-time firing, using the surface and bottom of embryo material basically identical (except for the special process such as tiles, tiles in the new fill glaze series).

- Q: What are the characteristics of the gas flow in the flame space of a glass furnace?

- Melting: mix into the glass melting furnace, at 1700 degrees of melting into glass liquid; 5, molding: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass; 6, annealing: the glass forming into the annealing furnace annealing, stress balance, prevent from breaking crack. Finally, inspection and packing.

- Q: Is glass fiber reinforced metal material?

- Glass steel (English: Glass Reinforced Plastic, GRP, or Fiber Reinforced Plastic, English: FRP) also known as glass steel or glass fiber reinforced plastic, is a kind of polymer with epoxy resin as matrix, glass steel or carbon fiber reinforced composite material by composite technology and made.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- In the sun or under the light, look at the projection, float shadow is very weak, light transmission of good, lattice black lines, one by one

- Q: What is the raw material of glass?.

- 1. the main raw material of glass(1): the main component of silica sand or borax borax glass is introduced into silica or silica or boron oxide, which alone can melt into a glass body in the combustion, determines the main properties of glass, appropriately called silicate glass or borosilicate glass.(2): the main ingredients of soda soda or salt and mirabilite into glass is sodium, they can with silica sand and other acidic oxides formed in the fusible salt calcination, the fluxing action, the glass is easy to mold. But if the content is too much, the thermal expansion rate of glass will increase, and the tensile strength will decrease.(3) limestone, dolomite, feldspar, etc.: the main component of limestone introduced into glass is calcium oxide, which enhances the chemical stability and mechanical strength of glass. But the content is too much, which makes the glass break and reduce the heat resistance.As a raw material for introduction of Magnesium Oxide, dolomite can improve the transparency of glass, reduce thermal expansion and improve water resistance.Feldspar, as a raw material for introduction of alumina, can control the melting temperature and increase durability. In addition, potassium feldspar can also provide components, improve the thermal properties of glass.(4) broken glass: Generally speaking, not all new materials are used in the manufacture of glass, but the broken glass of 15%--30%.

- Q: Failure reasons and solutions of insulating glass.

- The production of hollow glass raw material quality; key factors affect the service life of hollow glass sealant is ageing resistance and desiccant adsorption capacity, and the determining factor is the performance of sealant. Because no matter how much the desiccant adsorption capacity, inside the hollow glass after a certain limit, when the hollow glass desiccant completely saturated, again good desiccant also unable to water vapor adsorption, then the hollow glass is invalid. Only when the sealant has good sealing performance, moisture permeability coefficient is low, the amount of water vapor into the hollow glass rarely, and keep this state, only rarely can guarantee the hollow glass desiccant inside gas drying, so as to ensure the effect of hollow glass.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2008 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | Northern Europe, Africa |

| Company Certifications | Certificate for China Compulsory Product Certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Fire-resistant Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords