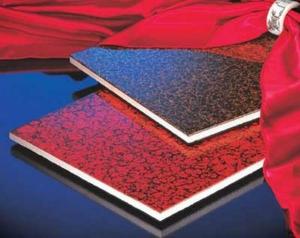

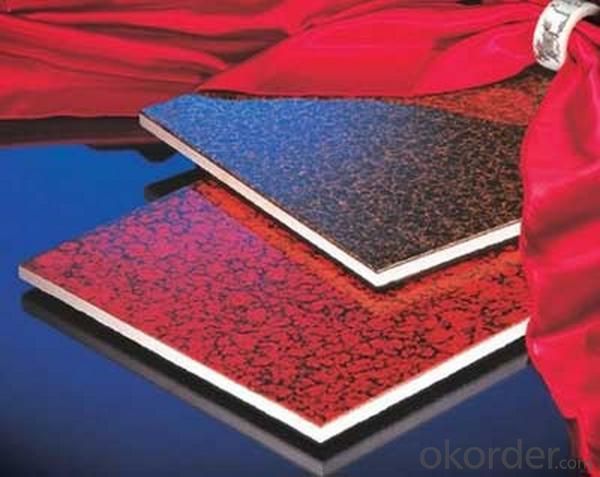

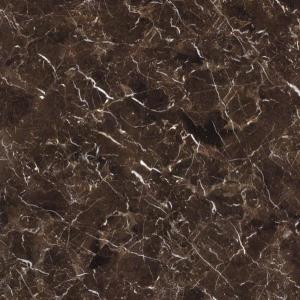

Microcrystalline Glass-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Microcrystalline Glass(Glass-ceramics) are polycrystalline material produced through controlled crystallization of base glass.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Spray glaze workshop generally volatile material is relatively small, so, as long as a good protection, do not spray out of the glaze and lungs can be. Ceramic factory occupational disease is mainly pneumoconiosis, but now most of the ceramic dust prevention in this area is much better than before.

- Q: What kind of glass is alkali free high borosilicate?

- Alkali free borosilicate glass has the characteristics of high surface smoothness, low coefficient of expansion, high temperature resistance, no alkali precipitation and good insulation. Without potassium and nano plasma, it is an important glass raw material for the electronics and Optoelectronics industries. In addition, they do not contain arsenic, antimony, barium, and halides.

- Q: I want to ask, if the home is already hollow glass, that still need to foil it?

- The insulating glass production enterprises are numerous, and the enterprise scale is relatively small. The quality of products is unstable. Products are good and bad, the phenomenon is more serious, even worse, inferior insulating glass is still flooding the market.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Do material testing (including stone moisture content, strength, steel and aluminum, chemical anchor pullout test, compatibility test of sealant, epoxy resin structural adhesive test), four test (water tightness, air tightness, wind pressure, plane deformation etc.)

- Q: What material is the simulation tree made of?

- Usually according to different kinds of trees, there are many kinds of trees. Such as banyan cement, glass steel, really, there is fresh coconut tree trunk type is a reference material preservation, as we & apos. Therefore, the simulation tree generally does not specify a certain material.

- Q: What are the raw materials made of glass and plastics?

- PVC PVC formula (CH - CH) n, is one of the most important types of vinyl polymers, is currently the world's second largest after the polyethylene plastic varieties. In domestic production in the plastic is in the first place. In the printing industry, often with PVC color rolled thin film and transparent glazing film making books, folders, tickets and other packaging decoration cover.

- Q: What is the raw material of glass? How is it converted to glass?

- Formed by converting molten glass to a solid product of a fixed shape. The process must take place within a certain temperature range. This is a cooling process. The glass is first converted from a viscous liquid to a plastic state, and then to a brittle solid. The forming method can be divided into two categories: manual forming and mechanical forming.

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are two kinds of molding process, high temperature molding (SMC molding) and room temperature molding (hand paste or vacuum assisted molding). SMC molded, there is no problem of glass fiber, hand paste or vacuum assisted molding. If it takes a long time, you will see the bare phenomenon of glass fiber. You can look at the back of his shell, and if you see the surface is not smooth, it should be hand shaped, usually if the car's output is very large, with SMC molding more. My humble opinion. I hope I can help you.

- Q: What is the raw material of glass?.

- Glass material is complex, but can be divided into main raw materials and auxiliary raw materials according to its function. The main material constitutes the main body of the glass, and determines the main physical and chemical properties of the glass. The auxiliary material endows the glass with special properties and facilitates the manufacturing process.

- Q: What is the glass industry?

- The glass belongs to the chemical industry, glass production process mainly includes: raw material processed. The massive raw materials (quartz sand, soda ash, limestone, feldspar) grinding, wet material drying, iron containing raw materials for iron removal treatment, in order to ensure the quality of glass batch preparation. 2. The melting of glass batch. High temperature in the furnace or crucible kiln (1550~1600) heating, so as to form uniform, no bubbles, and meet the requirements of molding liquid glass.

We are the professional producer of electronics glass.Our company has advanced technology and equipment.We have a management team rich in professional experiences and one of the top technical teams in the glass industry, and has advanced quality glass manufacturing in China over the past twenty years.

1. Manufacturer Overview

| Location | Zhejiang |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | Taiwan; Southeast Asia |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 70,000 square meters |

| No. of Production Lines | 16 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Microcrystalline Glass-4

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords