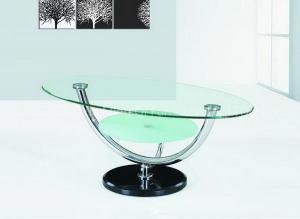

Low Temperature Painted Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Painting Glass is made by printing ceramic frit on float glass and by melting the colorant into the glass surface in the tempering furnace, in this way painted glass is manufactured with the performance of non-fading and multi-color.

Features of Low Temperature Painted Glass:

1、Various colors, stable and durable: Painted glass offers designers a wide range of color possibility, aesthetic value and variety and ceramic frit assures stable color.

2、Energy-saving: Painted glass can reduce air-conditioning cost by insulating solar heat.

3、Light building materials: Painted glass serves as a substitute for stone, tile, metal plate and reduces structural load on the external wall, making glazing easy.

4、High wind pressure resistance: Painted glass can be processed into laminated tempered glass or laminated heat-strengthened glass products.

Specifications of Low Temperature Painted Glass:

Thickness: 4-19mm

Max Size: 2500*4500mm

Min Size: 305*305mm

Applications of Low Temperature Painted Glass:

Painted Glass is widely used in façade, stained glass for interior partition, automotive glass, furniture and art glass, etc.

- Q: Is the production of glass materials as thin as possible? Why?

- Absolutely not!

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q: What is a hollow glass?

- The technical level of manufacturing hollow glass must be very high, to be also more difficult. The key lies in the quality of processing factories, high visibility point will do better. Hongguang glass company owns the most advanced glass processing equipment, equipment type complete automatic production line with hollow glass, has a professional R & D team, senior. In the manufacture of hollow glass which is an industry in the brothers ahead.

- Q: What are the cutting and cutting of acrylic and aluminum-plastic plates?

- Acrylic comes from English Acrylic, generic name for Acrylic acrylic and methacrylic acids chemicals. Including monomers, plates, aggregates, resin and composite material, acrylic acid methyl ester by methyl monomer (MMA) polymerization, namely polymethylmethacrylate (PMMA) organic glass plate, "organic glass" from the name "Oroglas" (a PMMA), from the "Organic Glass" (organic glass).

- Q: Comparison of plexiglass steel bridge and inorganic glass steel bridge

- 4, can release harmful gases, human health and environmental protection have a certain impact. 5, high cost, but also a larger fluctuation of raw material prices. 6, after the waste is not easy to handle. Two, inorganic glass fiber reinforced plastics (referred to as Magnesium Oxide) advantages: 1, high temperature. (under normal circumstances, Fahrenheit temperature of 400 degrees Celsius, to maintain the product is not deformed), 2, anti-aging, 20 years without deformation of the product. 3. Purify the air and absorb carbon dioxide from the air. 4, high strength. 5, waterproof performance is good. 6, light weight, only in plexiglass.

- Q: Can ordinary white glass (Bai Jiuping) replace quartz glass?

- Quartz glass has a series of excellent physical and chemical properties, such as: 1, high temperature resistance. The softening point temperature of quartz glass is about 1730 DEG C, which can be used for a long time at 1100 DEG C, and the maximum temperature can reach 1450 DEG C for a short time. 2, corrosion resistance. Except hydrofluoric acid, quartz glass and other acids almost no chemical reaction, the acid resistance is 30 times 150 times of ceramic, stainless steel, especially the chemical stability at high temperatures, any other engineering materials are incomparable. 3. Good thermal stability. The quartz glass thermal expansion coefficient is extremely small, can withstand the temperature changes, the quartz glass is heated to 1100 degrees Celsius, the water will not burst into the room. 4, good light transmission performance. The quartz glass has better transmittance in the whole spectral range from ultraviolet to infrared, and the transmittance of visible light is above 93%. Especially in the ultraviolet spectrum region, the maximum transmittance is above 80%. 5 、 good electrical insulation performance. The resistance of quartz glass is equal to ten thousand times of that of ordinary glass. It is an excellent insulating material. It has good electrical properties even at high temperature.

- Q: What is the raw material of glass?

- We know that solid materials can be divided into two categories: organic materials and inorganic materials. Organic materials are wood, plastic, plexiglass, cotton, wool, nylon and so on. Inorganic materials can be divided into three categories: single crystal, polycrystal and glass according to the structure. A single crystal has regular shapes and strict rules, such as the ruby is an alumina single crystal, the crystal is a silica single crystal, and the diamond is a single crystal of carbon. Polycrystal is a collection of large amounts of small single crystals, and all kinds of ceramics and metals are polycrystalline materials. Glass is a noncrystalline solid obtained by melting, cooling, and curing. Its structure has certain rules (short-range order) in the atomic and molecular range, but there is no rule (long-range disorder) in the macroscopic range.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- Float glass: float glass surface flat, good brightness, no bubble and tumorLattice glass: the surface of the lattice is not very smooth, and the ripples can be seen from the side. Uneven thickness

- Q: What is the density of glass flake cement?

- The bulk density of glass flake increases with the decrease of particle size.Glass flake resin (Glass flake mastic) is made of resin as binder, glass flake and powder, etc. it can be scraped and mixed with construction materials.

- Q: May I ask what specific aspects of German foam glass and foam glass made in China are?

- The domestic production line (excluding the line), you can imagine the bread, a fixed container, the raw material grinding and mixing placed in the container, into the furnace after foaming, molding and demoulding, manual cutting required size (note here will produce a large number of loss; 100%) not using waste glass.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai; Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 12000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Low Temperature Painted Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords