Thermal Conductivity Glass

Thermal Conductivity Glass Related Searches

Glass Wool Thermal Conductivity Fiberglass Thermal Insulation Construction Glass Fiberglass Temperature Resistance Glass Reinforced Epoxy Electrical Conductivity Of Fiberglass Computer Reading Glasses High Thermal Insulation Direct Roving Fiberglass Woven Fibreglass High Temperature Refractory Cement High Pressure Fiberglass Pipe Emulsion And Chopped Glass Chrome Magnesite Refractory Thermal Expansion Lamp Post Replacement Glass Refractories And Industrial Ceramics Glass Wool Tape Fibreglass Pipes Car Fiberglass Black Glass Fiber Tissue Frosted Plexiglass Ceramic Microfiltration High Temperature Plastic Ceramic Sheet Insulation Heating Thermostat Glass Wool Temperature Range Telescoping Hydraulic Cylinder Fiberglass Roving Model Glass Block Fiber Glass MatThermal Conductivity Glass Supplier & Manufacturer from China

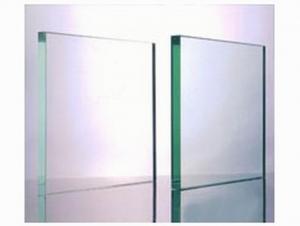

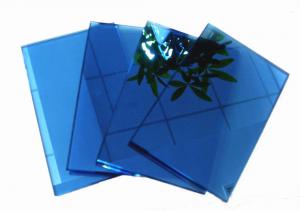

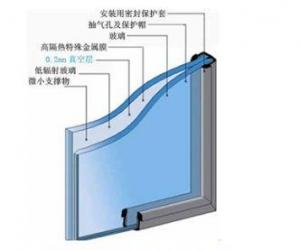

Thermal Conductivity Glass is a specialized type of glass engineered to possess superior thermal conductivity properties. This unique characteristic allows it to efficiently transfer heat, making it an ideal material for various applications where heat management is crucial. The product is designed to maintain its structural integrity and performance even under extreme temperature conditions, ensuring reliable and consistent results.Thermal Conductivity Glass finds its application in a wide range of industries, including electronics, aerospace, and automotive, where heat dissipation and temperature control are of paramount importance. It is used in the manufacturing of heat sinks, windows for high-temperature environments, and as a component in various thermal management systems. The product's ability to conduct heat effectively helps in maintaining optimal operating temperatures, thereby enhancing the performance and longevity of equipment and systems.

Okorder.com is a leading wholesale supplier of Thermal Conductivity Glass, boasting a vast inventory to cater to the diverse needs of clients across different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Thermal Conductivity Glass supplied meets the highest industry standards. By offering competitive prices and efficient delivery, Okorder.com has established itself as a trusted source for this essential product, helping businesses optimize their heat management solutions and achieve better performance.

Hot Products