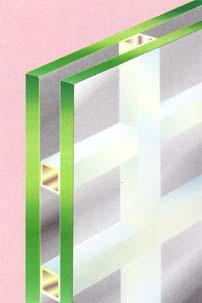

Good Quality Insulating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Glass is made up of two or more pieces of glass which are separated by metal frames, its edge is sealed with the glue by way of jointing and welding.

Features:

1. Heat preservation and energy conservation

2. Anti-frost and anti-dewing

3. Sound insulation

4. The aluminum bar is bent automatically. Automatic molecular-sieve filling system, vertical coupling and vertical automatic sealing can guarantee the production of high-quality insulating glass technically.

5. Compared with common insulating glass, the sealing is reliable for homogenous coating with no bulbs between the layers.

6. good appearance, good dew point

Specifications:

Thickness: 2-19mm

Size:

2500*5000mm(Max)

250*300mm(Min)

Applications:

Insulating Glass is mainly used as building glass in curtain wall, glass doors and windows, etc.

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- To have good quality, if the quality of other yarn nets, there may be broken.

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: What's the price of 0.85mm thick plexiglass, please?

- Import plate material is better, about 900, but the price is more expensive, generally do not consider adopting, unless their own customers request, and canAt an accepted price.

- Q: The difference between glass wool, rock wool, mineral wool

- Mineral woolCotton like short staple fibers made from silicate melts, including slag cotton, rock wool, glass wool and ceramic fibers, generally only refer to the first two.By the above two concepts, we should compare the difference between rock wool and slag cotton.

- Q: What material is the automobile glass made of?

- Among them, laminated glass refers to a transparent adhesive plastic film affixed to the two or three layers of glass, the plastic strength and toughness of glass and hard to combine together, increasing the glass's crushing resistance. Toughened glass refers to ordinary glass quenching. Internal stress was formed to some extent, so that the strength of the glass has been strengthened, the impact is broken, the glass will split into small pieces with a blunt edge, not easy to damage the occupant.

- Q: What is the difference between FRP and carbon fiber?

- Carbon fiber (carbon fiber, referred to as CF) is a new kind of fiber material with high strength and high modulus fiber with carbon content of more than 95%. It is a flaky graphite, microcrystalline and other organic fibers stacked along the axial direction of the fiber, obtained by carbonization and graphitization of microcrystalline graphite material. Carbon fiber "an hand in a velvet glove lighter than aluminum," the quality, but the strength is higher than that of steel, and has the characteristics of corrosion resistance, high modulus, in the national defense and civilian areas are important materials. It has not only the intrinsic characteristics of carbon materials, but also the softness and processability of textile fibers. It is a new generation of reinforced fiber.

- Q: What are the raw materials of water glass?

- The wet production of quartzite powder and caustic soda as raw materials in autoclave, 2 - 3 atmospheric pressure steam reaction, generating liquid water glass.

- Q: FRP process piping manufacturing process?

- A, lined with resin preparation. According to the quality control department according to the work environment, temperature conditions made resin formula system for lining resin matching, batching quantity according to the manufacturing schedule reasonable grasp. When the situation changes, the quality inspection department and the manufacturing department shall adjust the formulation in time, and prepare the resin according to the new formula;B, material preparation. According to the design requirements, the material needed for making the lining is transported to the designated position, and some wide width reinforcement materials are firstly cut and processed to the design width;C, lining production. According to the design requirements of the paving layer step liners, each layer in the process of laying under reasonable tension between the amount of overlap, and combined pressure roller rolling repeatedly from bubble to ensure fiber soaked completely. And requests each enhancement material layer to achieve the design resin content request;D, preliminary self check. According to the design requirements of overlay end of each layer, the operation requirements for quality testing of workers: whether the design meets the lining thickness, whether there is a local poor glue, hanging glue phenomenon, whether there is a white spot, whether there is a bubble, etc., if the occurrence of the above situation timely report and take measures;

- Q: What are the construction principles and raw materials of tempered glass?

- Tempered glass, also called toughened glass, is a kind of prestressed glass. It uses physical or chemical methods to form a compressive stress layer on the surface of glass. The glass itself has a higher compressive strength and will not cause damage. When the glass is subjected to external force, the pressure layer may be part of the tensile stress offset, avoid broken glass, although tempered glass is in large internal stress state, but the glass no internal defects, without causing damage, so as to achieve the purpose of improving the strength of glass. It is well known that microcracks on the surface of materials are the main causes of material rupture. Because the microcrack will expand gradually under the action of tension, and finally crack along the crack. And because of the large compressive stress on the surface of the glass, the microcracks on the glass surface become more fine and even heal under the action of extrusion".

- Q: Use of glass flake cement

- It has good compatibility and can be used as anticorrosive paint with various resins. Word of mouth

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1996 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 101 - 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Good Quality Insulating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches