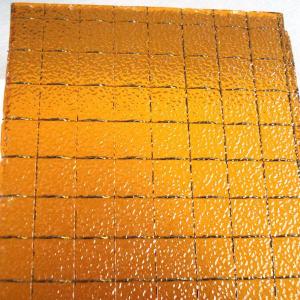

Fire-resistant Wired Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m.t.

- Supply Capability:

- 3000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

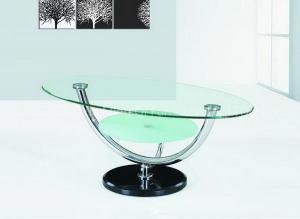

Wire glass is a kind of reinforced safe and decorative flat glass with wired mesh embedded in the glass by a special mesh unwinding system during glass forming.

Features of Fire-resistant Wired Glass:

Good optical property: the transmittance is the same as float glass.

High strength: its strength is 6-12 times the strength of common float glass, it belongs to a

kind of safety glass.It can be incorporated into insulating glass with the functions of energy saving, sound

insulation and heat insulation. It can also be used to process coating glass with the effect of

heat reflection and artistic beauty.

Specifications of Fire-resistant Wired Glass:

Thickness: 3-19mm

Size: 3660*2440mm

300*300mm

customized size

Applications of Fire-resistant Wired Glass:

Wired Glass is mainly used in construction such as curtain walls, doors and windows,

partitions, etc.

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Common is soda ash. Glass has silica, soda ash, sodium carbonate, high temperature heating. Paper generally use cellulose, bleaching powder. Detergent (mainly soap), usually sodium stearate

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so that the hollow {TodayHot} glass gradually eliminated.

- Q: What's the raw material for goldfish bowl?

- As for other containers: as long as you can hold water, do not fade, no smell, no harmful substances can be raised

- Q: What is the glass DV board made of?.

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and toughened glass made by special methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- General purchases of raw materials are their own, the general yacht above the bottom of the ship is a manufacturer, the ship is also a cloth manufacturers, as well as small boats on the yacht is also a manufacturer

- Q: Tempered and reinforced glass

- Enterprises producing safety glass must pass compulsory certification by the state, otherwise they are not allowed to appear on the market. Therefore, toughened glass has the following signs:Tempered glass, if made into reinforced glass, is substandard products.10mm toughened glass generally costs less than 100 yuan. Paint and not much money, but if the price is higher glaze.

- Q: Is glass fiber reinforced metal material?

- Not metal material. Glass steel (also known as glass fibre reinforced plastics, abbreviations and symbols internationally recognized as GFRP or FRP) is a variety of properties of the composite materials widely used separately. It is a new type of functional material made of synthetic resin and glass fiber by composite process. Glass fiber reinforced plastic material has the characteristics of light weight, high specific strength, corrosion resistance, good electrical insulation performance, slow heat transfer, good thermal insulation, good transient and ultra high temperature performance, and easy coloring, and can pass through electromagnetic wave and so on.

- Q: What material is used in the protective film in the middle of glass?

- At present, toughened glass membrane of glass raw materials generally have these brands. High end: Corelle & Schott. In the end: asahi. In the low-end: banxiaozi & luoyang.Just look different brands? The difference between JEANSWEST and Reaves? No, focusing on different materials.The same glass, medium and high-end glass called "aluminum silicon glass" in the low-end known as [sodium calcium glass]

- Q: The difference between natural crystal and crystal glass, merits and demerits!

- There are three distinct differences between crystal and glass:1. Sound: tap lightly or hit with your fingers. Crystal glass can produce metal crisp sound, accompanied by beautiful lingering. We will see in the clink reception, banquet scenes in the movie, crystal glasses collided with a clear voice will. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.2, feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be.3 gloss: turn a high grade crystal glass against the light, and you will find it is like a beautiful handicraft. White, glittering and translucent, and reflects the charming multicolored light, and low-end crystal or ordinary glassware in these areas there will be a big gap. What's more, in some ordinary glass containers, there are a lot of bubbles, and the color will be dirty and dark.

- Q: Use of glass flake cement

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale made of C- glass has excellent chemical durability.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | Nov. 30th, 2013 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Fire-resistant Wired Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m.t.

- Supply Capability:

- 3000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords