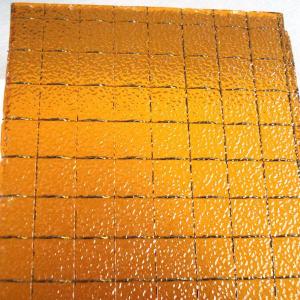

Fireproof Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 10000 Square Meter/Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Sheet Fireproof Glass is a special glass through chemical and physical treatment on the common glass.

Characteristic of Fireproof Glass:

1) Excellent Fire-resistance Performance.

2) It can keep well for more than 90 minutes under the 1000 degrees flame impact, it saves precious time for escape and fire disaster salvation.

3) High Strength Performance

4) It has excellent function of fire-resistance, meanwhile it has the prominent intensity and high rigidity, with the same thickness, the intensity is 6 to 12 times harder than float glass, is 2-3 times harder than tempered glass.Security Performance

5) When broken, the fireproof glass falls into small round granules, smaller than the fragment of the tempered glass, thus it will not hurt people.

6) Weather Ability

7) Comparing with the filling type or laminated fireproof glass, the most obvious characteristic of the single sheet fireproof glass is weather ability, besides the high intensity, under long time irradiation of the ultraviolet radiation, nothing changed on the surface or the function, it maintains bright and transparent for a long time.

Good ProcessabilitySingle-chip Fireproof Glass can be used directly or processed into Fire-resistant Laminated Glass, Fire-resistant Insulating Glass, Fire-resistant Curtain & Wall Glass, Fire-resistant Coated Glass, etc.

Structure | Fireproof Laminated glass | Fireproof Insulating Glass | Single Sheet Fireproof Glass |

Glass Structure | Single Sheet Fireproof Glass +PVB Film +Other Glass | Single fireproof Glass + Aluminum Airspace +Other Glass | Single Sheet Fireproof Glass |

Glass Shape | Flat, Curved, Etc. | ||

Function | Fire-resistance, Heat-Resistance, shield, Ultraviolet Radiation Resistance, Bulletproof, Save For Damage. | Fireproof, Thermal-insulation, Noise-resistance, Shielding, Anti-dew | Fireproof And Heat-insulation |

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so that the hollow {TodayHot} glass gradually eliminated.

- Q: Glass fiber raw material price increases, the impact on the glass fiber industry?

- A group of small and medium enterprises will face great pressure, especially the focus will be on reducing costs and expanding production, often ignoring product quality and marketing strategy, in the market competition in a disadvantageous position.

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- To have good quality, if the quality of other yarn nets, there may be broken.

- Q: Is the balance pad the raw material in the motor?

- Its main function is the use of mechanical energy into electrical energy, the most common is the use of thermal energy, water power, and so on to promote the generator rotor to generate electricity.

- Q: Can the toughened glass be cracked by the sun?

- high strengthThe toughened glass of the same thickness has 3~5 times the impact strength of ordinary glass, and the bending strength is 3~5 times of that of ordinary glass.

- Q: What is glass fiber reinforced nylon?

- With excellent wear resistance, heat resistance and electrical properties, high mechanical strength, self extinguishing, good dimensional stability, widely used in automotive industry products, textile products, pump impeller and first class precision engineering componentsPA6 enhancement series:With good wear resistance, heat resistance, oil resistance and chemical resistance, but also greatly reduce the water absorption and shrinkage of raw materials, with excellent dimensional stability and excellent mechanical strength

- Q: Will toughened glass break naturally?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: How do you pack something into (Qian Jin) plexiglass?

- The material is called a cold gel. First, some cold gel is injected into the mold, and then put into the specimen or other objects (Photos), then injected with cold gel, sealed, and then polished. Cold gels can be colored as needed. Cold gel products the biggest feature is not parting, what the image of the enclosure.

- Q: Samsung LCD panel information

- This screen is indeed the original Samsung screen, Samsung Electronics, Tianjin Corporation assembly production.TSEC is the sign of Tianjin's samsung. So he wrote the MADE IN CHINA (TSEC) behind him

- Q: What's the difference between crystal and ordinary glass?

- Feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be. Ordinary glass weight is more self-evident.

1. Manufacturer Overview

| Location | Zhejiang,China (Mainland) |

| Year Established | 1999 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Northern Europe |

| Company Certifications | TUV(GMC-GLOBAL MANUFACTURER CERTIFICATE); GB/T20041-2004 IDT ISO14001:2004; GB/TI9001-2008 IDT ISO9001:2008; GB/T28001-2001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,Ningbo |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Fireproof Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 10000 Square Meter/Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords