Clear Tempered Glass with 3C/CE/ISO Certificate 3mm-19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Clear Tempered Glass:

TEMPERED GLASS is made by heating flat glass to just below its softening temperature (650 °c) and suddenly chilling it with jets of cold air. It results in the outer skins under powerful compressive stress and the interior with severe tensile stress. In consequence, the impact applied to the glass will be overcome by the compressive stress on the surfaces to assure safety of use. It is ideal for areas with high wind loads and areas where human contacts are an important consideration.

2.Main features of Clear Tempered Glass:

.5 times harder than ordinary float glass, stronger resistance to thermal breakage than annealed or heat strengthened glass.

.Once breakage occurs, the glass disintegrates into small cubical fragments, which are relatively harmless to human body.

.It withstands abrupt temperature change of 220 Centigrade.

.Sizes are produced as per customer request. Once tempered, it can not be cut down.

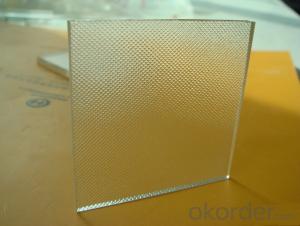

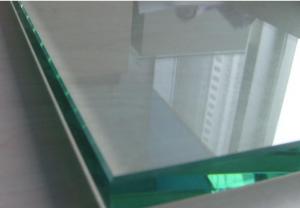

3.Clear Tempered Glass:

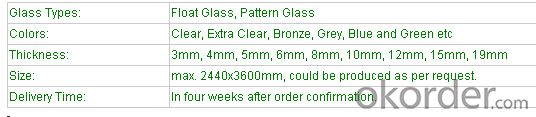

4.Clear Tempered Glass Specification:

5.Our factory

6.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What kind of material is glass made of?

- We know that solid materials can be divided into two categories: organic materials and inorganic materials. Organic materials are wood, plastic, plexiglass, cotton, wool, nylon and so on. Inorganic materials can be divided into three categories: single crystal, polycrystal and glass according to the structure. A single crystal has regular shapes and strict rules, such as the ruby is an alumina single crystal, the crystal is a silica single crystal, and the diamond is a single crystal of carbon. Polycrystal is a collection of large amounts of small single crystals, and all kinds of ceramics and metals are polycrystalline materials. Glass is a noncrystalline solid obtained by melting, cooling, and curing. Its structure has certain rules (short-range order) in the atomic and molecular range, but there is no rule (long-range disorder) in the macroscopic range. It can be made into various shapes by moulds.

- Q: What is the raw material for making glass?

- The raw material of glass is crystal sand, and the chemical component is silica

- Q: Glass fiber raw material price increases, the impact on the glass fiber industry?

- The relative decline in glass products on the market, glass prices higher, due to the decline in productivity, enterprises are also difficult to increase revenue through exports to expand production.

- Q: The main chemical constituents of ordinary glass

- The raw materials for making ordinary glass are soda ash, limestone and quartzThe composition of common glass chemical oxides (Na2O, CaO, 6SiO2), the main component is silica

- Q: What are the raw materials of glass fiber reinforced plastic?

- The concept of composite material means that a material can not meet the use requirements, and needs to be composed of two or more than two materials together to form another material that can meet the requirements of people, that is composite material. For example, a single kind of glass fiber, although high in strength, but the fiber is loose, can only withstand tension, can not bear bending, shear and compressive stress, it is difficult to make a fixed geometry, is loose software.

- Q: What are the materials for car windshields? Is there anything different than ordinary glass?

- At present, the front windshield of the car is mainly made of laminated glass and sandwich area toughened glass, and it can bear strong impact force.

- Q: Are there any materials that need to be tested in curtain work?

- Hidden works, batch inspection of raw materials, report, commencement report, division of engineering, engineering, testing report report is mainly hanging plate before the covert acceptance, including steel keel, anticorrosion material inspection, etc..

- Q: What happens when toughened glass breaks?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: Does the material of sunglasses choose good glass or plastic?

- Now, the most common use of sunglasses is resin lenses. The resin is a phenolic structure of chemicals, characterized by its light, high temperature resistance, impact resistance, and the ability to effectively block ultraviolet light. It should be said that this is a more excellent sunglasses, lens materials, polarized lenses made of this material will see more clearly.

- Q: Samsung LCD panel information

- This screen is indeed the original Samsung screen, Samsung Electronics, Tianjin Corporation assembly production.TSEC is the sign of Tianjin's samsung. So he wrote the MADE IN CHINA (TSEC) behind him

Send your message to us

Clear Tempered Glass with 3C/CE/ISO Certificate 3mm-19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords