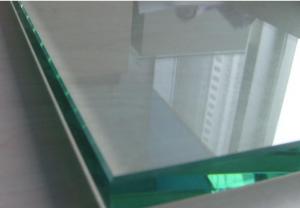

Tempered Glass 8/10/12/19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 2000 Tons per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Characteristics of Tempered Glass:

Safety: once breakage occurs, the glass disintegrates into small cubical fragements which are relatively harmless to human body.

High strength: 5 times stronger than annealed glass.

Excellent thermal stability: it withstands abrupt change of temperature.

2. Applications of Tempered Glass:

Window and door, Facades and curtain walls, Automobile, train, vessel, Furniture and decoration

3. Specifications of Tempered Glass:

Thickness: 3-19mm

Max size: 3660*9000mm, 2500*12800mm.

- Q: How is glass made?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q: Why is toughened glass broken?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: Who has information about power plants chimneys, water glass, acid resistant concrete?

- Water glass acid resistant concrete raw material: water glass, acid resistant concrete raw materials, including cementation material, curing agent, acid resistant aggregate and admixture. The composition of water glass and acid resistant soil is different, and the prepared concrete will have different properties and range of application. 1) cement material - water glass: building engineering usually use sodium silicate glass (including Na20). Divided into powder water glass and liquid water glass according to their different states. Liquid water glass is a fine quartz sand, S102 (or quartzite) mixed with sodium carbonate in a certain proportion, placed in a furnace of 1350 - 1400 DEG C, and cooled by melting reaction to be a semi-finished product of solid water glass. The solid water glass is put into the autoclave, and the water vapor is dissolved into water so that a practical liquid water glass can be obtained. The liquid water glass can be obtained by two times of spray drying, which is usually called sodium silicate powder. The modulus and specific density of water glass have great influence on the properties of concrete. In order to guarantee the technical performance of acid proof concrete, the water glass of suitable modulus and specific density must be chosen. According to the experience of acid proof construction, water glass modulus 2 is recommended. From 6 to 3.O, the corresponding specific density is from 1.38 to 1.40. Water glass appearance is colorless, slightly blue transparent or translucent viscous liquid.

- Q: What is the ratio of raw materials for glass mildew proof powder?

- Coconut shell plant essence ("compendium") from endocarp for palm plants in coconut. Coconut palm in plant form. The chemical composition of coconut shell containing 0.61% ash, 36.51% lignin, cellulose 53.06%, pentosan (29.27% total). Cellulose containing 20.54% pentosan, principal components in the ash and koh.

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- I do PVC mesh fabric, and it should be used on the hull of your yacht

- Q: What is the difference between FRP and carbon fiber?

- Glass fiber (formerly known as English: glass fiber or fiberglass) is a kind of excellent inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance. It is a glass ball or waste glass as raw materials by high temperature melting, wire drawing, winding and weaving process for production, the filament diameter of several microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers by hundreds or even thousands of root root filaments. Glass fiber is usually used as reinforcing material in composite materials, electrical insulation materials and insulation materials, circuit boards and other fields of national economy.

- Q: Does fiberglass contain formaldehyde? I'm a hair salon. Buy a glass fiber reinforced plastic shampoo bed, there is always a pungent smell of the body, there is no harm to it, including formaldehyde free

- The pungent smell is not necessarily formaldehyde, and FRP is also called GRP, that is, fiber reinforced plastics, generally refers to glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix.

- Q: What happens when toughened glass breaks?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.

- Q: Does the material of sunglasses choose good glass or plastic?

- Now, the most common use of sunglasses is resin lenses. The resin is a phenolic structure of chemicals, characterized by its light, high temperature resistance, impact resistance, and the ability to effectively block ultraviolet light. It should be said that this is a more excellent sunglasses, lens materials, polarized lenses made of this material will see more clearly.

- Q: Why is the process of glass toughened always broken?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | South America 28.97 Eastern Europe T 9.66 Southeast Asia 0.63 Africa19.31 Oceania 1.45 Mid East 14.49 Eastern Asia14.49 Western Europe 1.11 Central America 4.83 Northern Europe 0.96 Southern Europe 1.59 South Asia 0.48 North America 2.03 |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | percent of export |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tempered Glass 8/10/12/19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters m²

- Supply Capability:

- 2000 Tons per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords