Curved Tempered Glass 4-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters Bent tempered glass sample is available m²

- Supply Capability:

- 10000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Curved Tempered Glass

Packaging Details: Wooden crates with paper between each two sheets

Delivery Detail: Within 15 days after received deposit or L/C at sight

Specifications of Curved Tempered Glass

1.Bent Tempered Glass

2.10 years' experience

3.Best quality with CE & ISO9001

4.Competitive price and quick delivery

Bent Tempered Glass adopts the similar process with tempered glass, but before the cooling process, using the external power bent the glass to a proper radian according to the requirement, its wind pressure resistance is better than flat tempered glass and other kinds of glass for the special shape. It widely use in esthetics architecture field for the beautiful appearance.

Application of Curved Tempered Glass:

Facades and curtain walls

External walls of revolving doors and exposed elevators

Stairs, handrails, skylights

Partions, display shelves and furniture

Specifications of Curved Tempered Glass:

Thickness: 4-19mm

Min. Size: 220*430mm

Max. Size: 2440*4200mm

Curve depth: up to 500mm

Bending angle: up to 90’’

Quality Standards:

GB 15763.2, Chinese standard.

EN 12150.1, European Standard.

AS/NZS 2208, Australian standard.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Spray glaze workshop generally volatile material is relatively small, so, as long as a good protection, do not spray out of the glaze and lungs can be. Ceramic factory occupational disease is mainly pneumoconiosis, but now most of the ceramic dust prevention in this area is much better than before.

- Q: Glass fiber raw material price increases, the impact on the glass fiber industry?

- The relative decline in glass products on the market, glass prices higher, due to the decline in productivity, enterprises are also difficult to increase revenue through exports to expand production.

- Q: What material is the simulation tree made of?

- Usually according to different kinds of trees, there are many kinds of trees. Such as banyan cement, glass steel, really, there is fresh coconut tree trunk type is a reference material preservation, as we & apos. Therefore, the simulation tree generally does not specify a certain material.

- Q: The benefits of natural thin wood planks

- Sheet material means a flat rectangular building material plate with a width of more than 2 times its thickness, usually made of flat rectangular building material, used as a wall, ceiling, or floor member. Also refers to the forging, rolling or casting of the metal plate, divided into thin plate, medium plate, thick plate, thick plate, usually made of standard size flat rectangular building material board.

- Q: There are several appearances of the quality defects of ordinary flat glass

- There in the flat glass some prominent particles, called big lump or small stones, called sand. It mainly affects the optical properties of glass and makes it difficult to cut glass.

- Q: Comparison of plexiglass steel bridge and inorganic glass steel bridge

- Organic glass fiber reinforced plastics and inorganic glass fiber reinforced plastic properties of one, plexiglass resin (referred to as resin) advantages: 1, good toughness; 2, high strength; 3, waterproof performance is good; 4, light weight. (the weight of inorganic glass of the same size is about 1.2 times of that of plexiglass) and the disadvantages of organic glass fiber reinforced plastics: 1. Not high temperature resistant. (in general, the temperature is 70 degrees Celsius, it has begun to deform) 2, no aging resistance. (affected by ultraviolet light, easy to deformation, fade) 3, easy to burn.

- Q: Glass fiber reinforced plastic (FRP) is a new type of composite material. What is the raw material?

- Glass fiber reinforced plastics have the advantage of high strength:Ordinary glass is a brittle material of low strength. If fused glass is made into very fine glass fiber, its properties change greatly. Glass fibers are soft and can even be woven into cloth. At the same time, the thinner the glass fiber, the higher its strength. The strength of GRP can be compared to that of reinforced concrete. In reinforced concrete, the main force to bear external force is steel, but concrete is indispensable, it will bond the steel as a whole, not only gives the building components in a definite shape, but also increase the strength. In glass fiber reinforced plastics, glass acts as reinforcing steel, while bakelite acts as concrete. The combination of the two makes glass fiber steel an amazing strength.Glass fiber reinforced plastics not only has high strength, but also has excellent corrosion resistance, thus becoming an important corrosion-resistant material. Lead, once a corrosion resistant metal material, is resistant to sulfuric acid, which is highly corrosive. The reason is that the formation of Pb and concentrated sulfuric acid to dissolve lead sulfate, become a kind of protective film on the surface of the dense metallic lead, so the chemical reaction kettle and lead lined pipes used, can also be used for enamel liner. If fiberglass is used, the corrosion resistance meets the requirements. Also used for glass steel valves, pumps, fans, suitable for the transport of corrosive liquid tank car and train tanker, waste acid waste liquid pool in the village and a large area in the storage tank, chemical plant production storage corrosive liquid corrosion on the ground. The corrosion of petroleum is also very strong, and glass fiber reinforced plastics can be used instead of steel pipes to make oil pipelines and oil trucks, which greatly saves the steel.

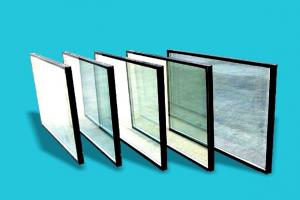

- Q: How to identify and select high quality insulating glass?

- The raw materials of the latter two kinds of insulating glass are glass, aluminium strip, insert angle, butyl glue, double component polysulfide glue or silicone rubber, drying agent and compound sealant.Jieyang Hongguang glass is a special glass, customer service very detailed answer.

- Q: What does GF30 represent in plastic PP GF30?

- The rigidity is better. It is suitable for producing pressure plate frame, chemical container, accumulator shell, fan blade, automobile lamp housing, automobile steering wheel, electric appliance coil frame and so onHope to be of some help to you

- Q: How do you pack something into (Qian Jin) plexiglass?

- The material is called a cold gel. First, some cold gel is injected into the mold, and then put into the specimen or other objects (Photos), then injected with cold gel, sealed, and then polished. Cold gels can be colored as needed. Cold gel products the biggest feature is not parting, what the image of the enclosure.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | South America 28.97 Eastern Europe T 9.66 Southeast Asia 0.63 Africa19.31 Oceania 1.45 Mid East 14.49 Eastern Asia14.49 Western Europe 1.11 Central America 4.83 Northern Europe 0.96 Southern Europe 1.59 South Asia 0.48 North America 2.03 |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | percent of export |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Curved Tempered Glass 4-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters Bent tempered glass sample is available m²

- Supply Capability:

- 10000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords