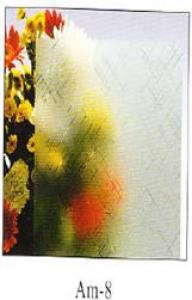

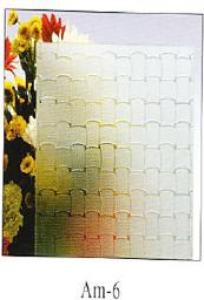

Acid Etching Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Acid Etching Glass, which is fingerprint-proof, can be etched either a single side or both sides.

Features:

A wide range of colors and patterns:

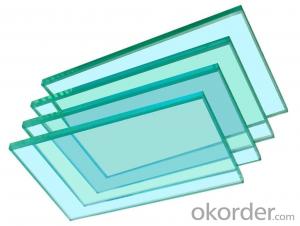

Specifications:

Thickness: 2-12mm

Size:

3300*2440mm

300*300mm

customized size

Applications:

Acid Etching Glass is mainly used for indoor decorations like doors, windows, screens, partitions, furniture, handrails, enclosures, fences, etc.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Because I work in the glass curtain wall project, only know raw materials to do a glass curtain wall material impact strength test before installing the unit model, in a special laboratory, no experimental requirements should be in the process of construction, the construction of the end of may do some water resistance experiment. Hope to be of help to you!

- Q: Polypropylene short fiber and glass fiber if different

- Polypropylene fiber is a high polymer material that can burn. Glass fiber is inorganic material and can not burn.

- Q: Is the balance pad the raw material in the motor?

- An electric machine is an electromagnetic device that converts or transfers electrical energy according to the law of electromagnetic induction. In a circuit, use the letter M (the old standard uses D). Its main function is to generate driving torque, as a power source for electrical appliances or various machines. The generator is represented by the letter G in the circuit.

- Q: What is the difference between white float glass and ordinary float glass?

- The iron oxide content of ultra white float glass is low, so the raw materials (sand or sandstone) to low iron content, iron content can be the best sand control below 0.03%

- Q: Raw material, processing method and ratio of glass fiber reinforced plastic

- The proportion of glass fiber reinforced plastic material is the business secret of each glass fiber reinforced plastic processing enterprise, and will not be easily informed.

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber is divided into different grades according to its composition, properties and uses. According to the provisions of the standard level (see table), E glass fiber is most widely used, widely used in electrical insulating materials; special fiber grade S, while the output is small, but very important, because it has super strength, mainly used for military defense, such as bullet proof box; C level more than E with chemical resistance in the battery isolation plate, chemical filter; a basic glass fiber reinforced materials used in the production.The main component of glass fibre and its main components are silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide, depending on the amount of alkali content in glass, can be divided into non alkali glass fiber (Na2O 0% ~ 2%, which belongs to the aluminum borosilicate glass), glass fiber (8% ~ sodium sodium calcium silicate glass 12%, a boron containing or not containing boron) and high alkali glass fiber (Na2O 13%, sodium calcium silicate glass).

- Q: What is the raw material of glass? How is it converted to glass?

- According to the designed material sheet, the raw materials are weighed and mixed evenly in a mixer. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.

- Q: How is glass made, raw material proportioning?

- The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000)

- Q: What material is used in the protective film in the middle of glass?

- At present, toughened glass membrane of glass raw materials generally have these brands. High end: Corelle & Schott. In the end: asahi. In the low-end: banxiaozi & luoyang.Just look different brands? The difference between JEANSWEST and Reaves? No, focusing on different materials.The same glass, medium and high-end glass called "aluminum silicon glass" in the low-end known as [sodium calcium glass]

- Q: Is flat glass the main material or structural component in raw materials?

- The general case is the principal. Such as doors and windows, glass, glass partition, ceiling, and so on.

Our main product is glass, such as tempered glass, furniture glass, building glass, silkscreen printed glass, painted glass, sandblasted or acid etched glass, and more. Our products are widely used for architecture, electronics, and furniture, such as table tops, coffee tables, LCD TV bases, refrigeratory or air-condition front panels, exchange rate indicators, horologe panels, induction cooker panels, cabinets, shower glass doors, and other furniture.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1989 |

| Annual Output Value | US$ 1.0-1.5 Billion |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Acid Etching Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords