Clear Float Glass Manufacturer 2-19mm Good Quality Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Clear Float Glass:

Clear Float Glass is the highest quality clear float glass with smooth surface. Characterised by its uniform thickness, SGG Clear Float is highly popular in the construction of architectural exteriors and interiors, shop windows, showcases, mirrors, furniture, tabletops, and so on.

2.Main features of Clear Float Glass:

.SGG Clear Float Glass is a high-quality glass with precise surface flatness which ensures 100% distortion-free vision.

.It has a crystal clear finish which ensures perfect clarity of vision, with both true and reflected images appearing very bright and clear with this glass.

.Due to its superior quality of manufacture, SGG Clear Float Glass has a sparkling and brilliant luster.

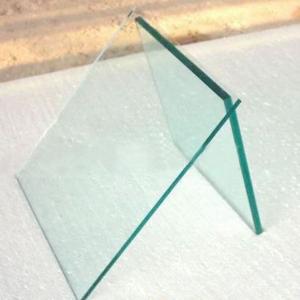

3.Clear Tempered Glass:

4.Clear Tempered Glass Specification:

5.Our factory

6.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Ceramic crystallization: glass ceramic composite board is the product of "three in one" of glass, ceramic and stone craft. It combines the glass melting process, ceramic brick molding and crystallization sintering process, stone polishing, cutting process as a whole. In short, microcrystalline glass frit is special stalls shop in the special ceramic tile on the roller kiln sintering crystallization, after polishing and cutting timber.

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Acrylic board and plexiglass"Organic glass" from English Organic Glass. in recent years in some areas will be made of transparent plastic sheet all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called the acrylic plate.

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- To have good quality, if the quality of other yarn nets, there may be broken.

- Q: Glass factory raw materials specific to do?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history. The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value. The main difference is that the raw material used in the quartz sand is superior and the iron content is very low (usually under 3/10000)

- Q: Why a broken glass film

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: How is glass made? What is its raw material?

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and toughened glass made by special methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q: What does GF30 represent in plastic PP GF30?

- (PP) polypropylenePP-GF30 glass fiber reinforced polypropylene content of glass fiber 30%

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- Ordinary glass float line cooling is a long process, the glass also has compressive stress, but the compressive stress is small, uneven distribution

- Q: Will toughened glass break naturally?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: Why is the process of glass toughened always broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

Send your message to us

Clear Float Glass Manufacturer 2-19mm Good Quality Competitive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches