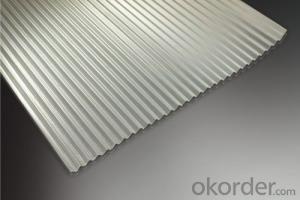

aluminum 4ft x 8ft sheets corrugated roofing sheet roof tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification

| commodity | aluminum 4ft x 8ft sheets corrugated steel roofing sheet color steel roof tile roofing |

Grade | SGCC SGCH DX51D |

Standard | ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008 AS1397-2001, EN10215-1995, ASTM A792M-02, JIS G3321-1998 |

Basal plate | Cold rolled steel coil ,hot dipped galvanized/galvalume steel coil |

Zinc Coating | Z30-Z275G/m2, AZ30-150g/m2 |

Thickness | 0.13-0.9mm |

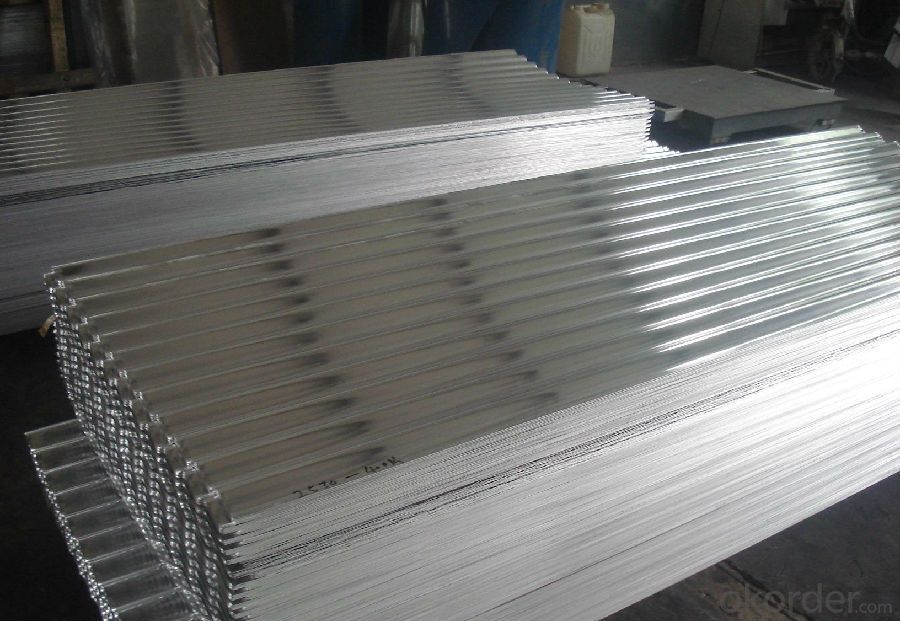

Width | 750-1250mm(before corrugation) 600-1050mm(after corrugation) |

Wave depth | 18(+/-2mm),etc |

Wave distance | 76(+/-2mm),etc |

| color | according to RAL |

| length | as your requestment |

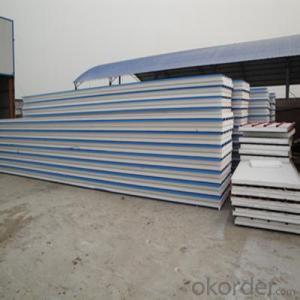

| Product feature | water resistance,light weight,easy installation,aesthetic,high tensile |

| Packing | standard export water-proof package with steel strips fixed |

| Coating | Top:10-25um back:5-10um |

| Application | exterior and interior wall,roofs,and soffits |

| Advantages | 1.Design according to customers 'requirements 2.Production under ISO9001-2008 Quality System 3.Easy to be installed as light weight 4.Z360-275/AZ30-150 is suitable for many application 5.Our products are recyclable materials 6.The less construction period, the more using time. |

Production line

We have six producting line of color aluminum tile. Our annual output is 8000 ton,due to the most advanced and mordern lines

why choose us

our advantage of color steel tile

1.corrosion resistance

2.light weight:Metal covered and metal frame buildings offer the safest possible shelter during the storms. Correctly earthed aluminium, because of its high electrical conductivity, offers excellent protection from lighting damage.

3.High strength:bending and compression resistance, used as building enclosure and bearing structure

4.Easy to install:no need special tools, do not break, crack or leak.

5.Energy-saving:saving of the structural steel by up to 40%.

6.Beautiful design

7.Quake-proof, fire-proof, rain-proof.

8.It can be recycled and good for environments.

our service for you

pre-sale service

1.sample free

2.We have full stock and can deliver within short time

3.Dood quality+factory price+quick response+reliable service

4.All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

After you choose

1.we will count cheapest shipping cost and make invoice to you at once

2.check quality again,then send out to you at 5-10 working day after your payment

3.email you the tracking No,and help to chase the parcels until it arrive you

After sale choose

1.we are very glad that customer give us some suggestion for price and products

2.If any question,please contact with us freely by E-mail or telephone

Our products are very popular to be exported to the Russian market,Korea South-East Asia,India,Middle-East,Africa,North-Europe,South- America,and so on.

- Q: How do you prevent warping of aluminum sheets during bending?

- One way to prevent warping of aluminum sheets during bending is by using proper techniques and tools. This includes using the correct bending radius, ensuring even distribution of pressure along the sheet, and employing a suitable clamping method to hold the sheet in place during the bending process. Additionally, preheating the aluminum sheet can help to reduce the likelihood of warping.

- Q: What are the common applications of aluminum sheets in construction?

- Aluminum sheets are commonly used in construction for a variety of applications. They are used for roofing, siding, and facades due to their lightweight nature and corrosion resistance. Aluminum sheets are also used for window frames, doors, and curtain walls. Additionally, they are utilized for insulation purposes as well as in structural components such as beams and columns.

- Q: How are aluminum sheets different from aluminum plate?

- Aluminum sheets and aluminum plates differ in terms of thickness. Aluminum sheets are usually thinner, ranging from 0.2 mm to 6 mm, while aluminum plates are thicker, typically starting at 6 mm and going up to several inches. Additionally, aluminum plates are often used for structural applications, while aluminum sheets are commonly utilized for decorative or non-structural purposes.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- This Site Might Help You. RE: Steel or aluminum alloy rims? Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100. Should I take it? Or just stick...

- Q: why can aluminum sheet after oxide film removal react quicker with hydrochloric acid?

- the reason is very simple, the original aluminum sheet has a layer of dense oxide film AI2O3, which has prevented the inner aluminum sheet from reacting with hydrochloric acid. but after oxide film removal, aluminum sheet will directly contact hydrochloric acid, generating H2.

- Q: What are the different bending methods for aluminum sheets?

- Aluminum sheets can be bent using different methods, each with its own advantages and limitations. Various bending techniques for aluminum sheets include: 1. Air Bending: By utilizing a punch and die, a bend is formed in the aluminum sheet without direct contact. Compressed air is employed to exert force on the sheet, resulting in the desired bend. Air bending is a versatile method that allows for a range of bend angles and radii. 2. Bottom Bending: This method involves clamping the aluminum sheet between a V-shaped die and a flat die. A punch is then used to press the sheet into the V-shaped die, creating the desired bend. Bottom bending is suitable for achieving sharp bends with small radii. 3. Coining: Precise and crisp bends are formed by applying high pressure to the aluminum sheet between a punch and a die. Coined bends exhibit minimal springback. However, this method requires specialized equipment and is typically utilized for high-volume production. 4. Roll Bending: By passing the aluminum sheet between a set of rollers, it is gradually bent into the desired shape. Roll bending is commonly employed for creating cylindrical or conical shapes. This technique can achieve large radii and is suitable for thicker aluminum sheets. 5. Press Brake Bending: This commonly used method employs a hydraulic or mechanical press brake to create bends in aluminum sheets. The sheet is clamped between a punch and a die, and the press brake applies force to create the bend. Press brake bending offers flexibility in terms of bend angles and radii. It is important to consider various factors such as the desired bend angle, radius, material thickness, and specific application requirements when selecting a bending method.

- Q: What is the typical yield strength of aluminum sheets?

- The yield strength of aluminum sheets can differ based on the grade and thickness of the sheet. On average, the yield strength of aluminum sheets falls within the range of 30 to 100 MPa (megapascals). It should be noted that this is a broad range, and specific aluminum alloys may exhibit higher or lower yield strengths. Moreover, factors like heat treatment and processing conditions can also impact the yield strength.

- Q: What is the surface hardness of aluminum sheets?

- The alloy and treatment process play a role in determining the surface hardness of aluminum sheets, which can vary. In comparison to metals like steel or titanium, aluminum sheets generally have a lower surface hardness. However, heat treatment can enhance the hardness of certain aluminum alloys. For instance, 6061-T6 aluminum sheets exhibit a surface hardness of approximately 95 Brinell, whereas 7075-T6 aluminum sheets have a surface hardness of around 150 Brinell. It is worth mentioning that these values are approximate and subject to variation based on the particular alloy, temper, and processing conditions.

- Q: What types of aluminum sheets are recommended for use in cold climates?

- <p>Yes, there are specific types of aluminum sheets suitable for cold climates. These include 3003-H14 and 5052-H32 aluminum sheets. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for cold weather applications. 5052-H32 offers high strength and good corrosion resistance, which is beneficial in extreme cold conditions. Both types can withstand low temperatures without significant loss of strength or ductility, ensuring reliability and durability in cold environments.</p>

- Q: What are the typical uses or applications for 101 aluminum sheets?

- 101 aluminum sheets are commonly used in a variety of applications such as roofing, siding, gutters, and general construction due to their excellent corrosion resistance, high formability, and durability. They are also utilized in the automotive industry for body panels, trims, and interior components. Additionally, 101 aluminum sheets are often used for packaging, electrical enclosures, and kitchen equipment due to their lightweight nature and ability to withstand various environmental conditions.

Send your message to us

aluminum 4ft x 8ft sheets corrugated roofing sheet roof tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords