Graphite Powder Pinewood Derby - Natural Flake Graphite (Expandable Graphite)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

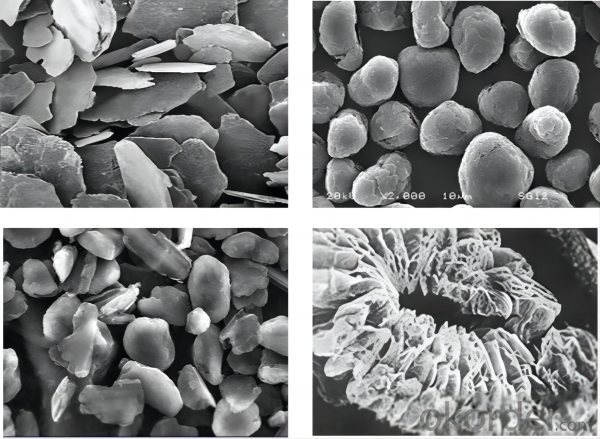

Natural Flake graphite

Relying on the advantages of liumao graphite resources, we develop deep processing of natural

graphite. The main products include fine graphite powder, natural graphite anode materials for

lithium-ion batteries.

The production capacity is:

1). 100,000 ton of fine graphite powder;

2). 50,000 tons of natural spherical graphite;

3). 50,000 tons of Purifying capacity;

4). 40,000 tons of anode materials;

5). 10,000 tons of expanded graphite, graphene, silicon-carbon anode and other graphite

deep-processing products. Our products have been continuously exported to over 30 countries

including the United States, the UnitedKingdom, India, Japan, and South Korea etc.

Product Range:

•Graphite fine powder- Mainly used in the production of refractory materials,

main products: -193, -194, -195, 196, +195, +895, +595, etc. more than 80 varieties.

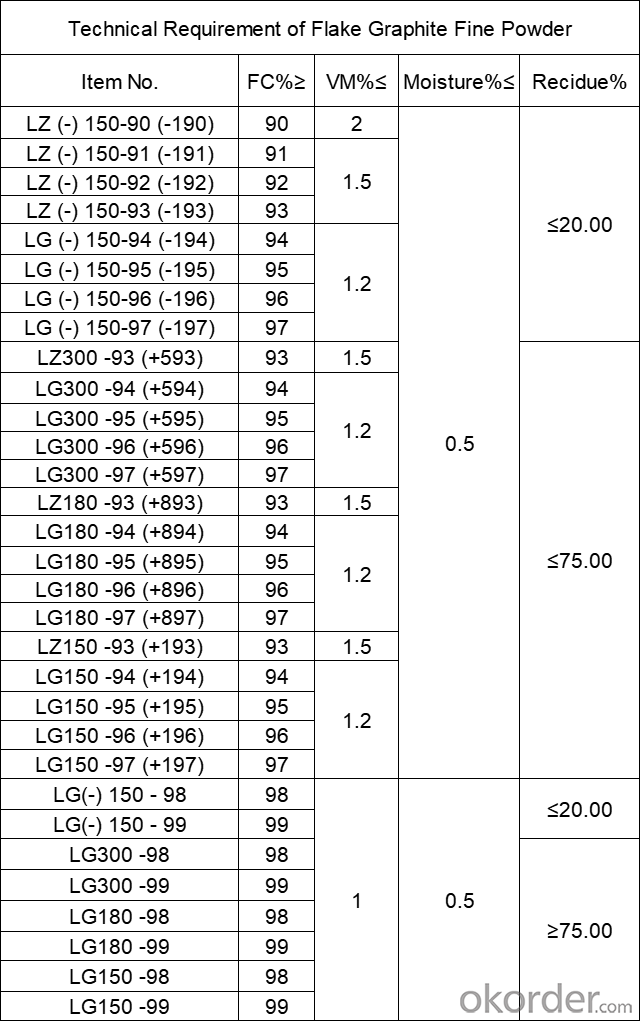

For details, please check Table 1.

Table 1:

•Graphite deep processing products - Natural graphite negative electrode materials,

main products:

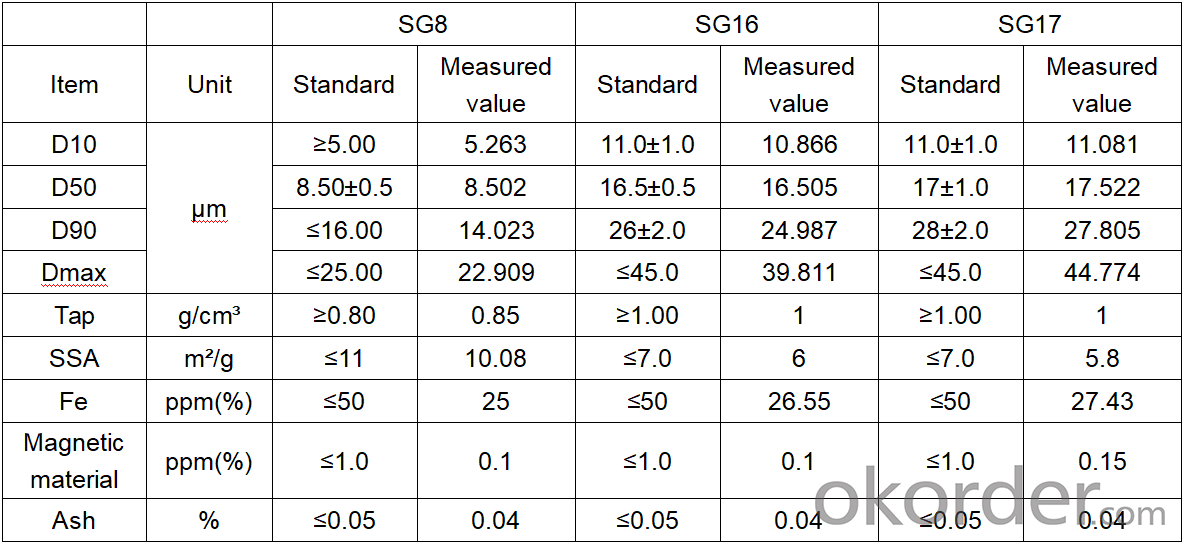

1. Spherical Graphite GS8, SG10, SG16, SG17.

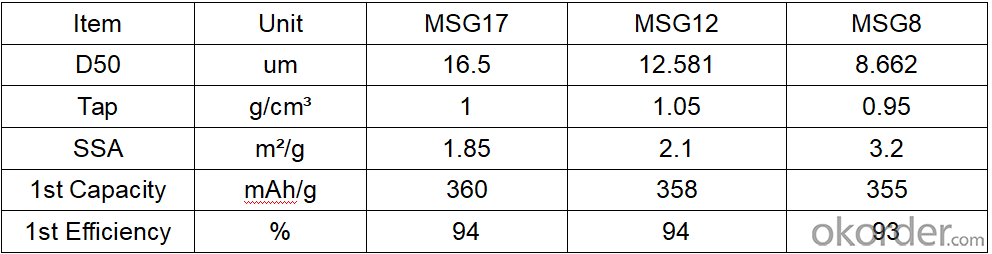

2. Negative electrode material MSG10, MSG16 and MSG17 etc. more than 10 products .

For details, please check Table 2 and Table 3.

Table 2: Spherical Graphite

Table 3:Negative electrode material

Advantages:

•Resource:

1.Proven resource storage is 236 million tons, possess graphite mining rights.

2.It is a rare high-quality large flake graphite resources in the world.

•Production:

1.Annual production capacity is 80,000 tons.

2.Possess substations, tailings ponds, and special railway lines

3.Mature production technology, deeply cultivated graphite mining and selection for more than 80 years.

- Q: How does graphite powder solidify into a lump? What bond is best used?After solidification can be more than 1000 degrees high temperature does not change

- There is no binder that can withstand 1000 degrees C. At such a high temperature, any binder has been carbonized and has lost its bond effect, so it is impossible if you want to use the binder to make the graphite powder into pieces

- Q: Are sand and particle powders used for casting quartz sand? Detailed and accurate.

- Casting molding mainly used for special silica sand, zircon sand, magnesia and chromite, pearl sand, graphite sand. Casting powder mainly used in coatings, such as: quartz powder, bauxite powder, zircon powder, graphite powder, etc.

- Q: Is oxygen allowed in the oxygen pipe?

- To tell the truth, the graphite powder also belongs to small particles, if the medical oxygen pipe can not have graphite, if industrial oxygen, can have the physical and chemical properties of graphite, graphite and other stable, will not react, to a certain extent is a kind of preservatives, prevent oxidation function.

- Q: Can graphite powder be used for concrete?

- Generally, stone toner is not used for concrete.There is no standard used or not used in this respect.Individuals believe that in order to form black concrete, it is feasible to add a small amount of graphite powder to concrete, but it should be proved to be in conformity with concrete standards and shall be reported to the business management department for approval. In other cases, even graphite powder can be used for concrete and is also a waste of resources. From the point of view of resource saving, graphite powder should not be used in concrete.

- Q: Like the wolf, adding graphite powder in the failure of electronic instrument air explosion in aircraft rocket season, really make it

- The graphite bomb is real, but the main is to destroy the enemy power plant and other fixed objects, the damaged helicopter is unlikely, because the rocket explosion scope is limited, that not what eggs with graphite. It's better to use a bullet warhead than a graphite warhead.

- Q: Can graphite powder be found in plastic?

- Can effectively improve these shortcomings of plastic, so graphite powder can be used in plastic, and I hope to help you, I hope to adopt, thank you very much.

- Q: Can ultrafine powder iron conduct heat? How many purpose graphite powder can be called superfine stone powder? Pingdu graphite powder which good?

- Ultrafine toner is a thermal conductive function, because ultrafine toner is processed from natural graphite, which inherits the characteristics of natural graphite conduction and heat conduction.

- Q: Why can graphite powder conduct electricity?

- Pure graphite in nature is not there, which often contains Si02, A1203, Fe0, CaO, P2O5, Cu0 and other impurities. These impurities often appear in quartz, pyrite, carbonate and other minerals. In addition, there are water, asphalt, CO2, H2, CH4, N2 and other parts of the gas. Therefore, the determination of graphite, in addition to the determination of fixed carbon content, but also the simultaneous determination of volatile and ash content.

- Q: Graphite powder made of graphite oxide, how much weight gain?

- The official name of graphite oxide is graphite oxide, or "graphite acid". It is a compound composed of carbon, hydrogen and oxygen elements with different mass ratio. Oxidized graphite can be prepared by treating graphite with a strong oxidizing agent. Of the products obtained, the highest degree of oxidation is a ratio of carbon to oxygen, between 2.1 and 2.9 yellow solid, and still retains the layered structure of graphite, but the structure becomes more complex.

- Q: Does the graphite powder cause explosion? If so, how to prevent the production of graphite products in the workshop?

- Dust produced in the process of production of some factories and mines, especially the dust produced in the processing of some organic matters, will explode and burn under certain conditions.(2) adequate air and oxidizing agents;(3) there is fire or strong vibration and friction.Such as effective ventilation and biological film, dust suppression technology, integrated dust suppression technology, dust removal measures, smoking and fire operations are prohibited. A pressure relief valve or other device is arranged in the outer shell of the equipment, and an explosion containment system is adopted. For factories with dust explosion hazards, the design must be strictly carried out according to the technical grade of explosion protection, and ventilation and dust removal systems shall be installed separately. Often wet cleaning workshop floor and equipment, to prevent dust flying and gathering. Ensure that the system has a good airtight, if necessary, in airtight containers or pipes in the flammable dust filled with nitrogen, carbon dioxide and other gases, in order to reduce the content of oxygen, dust suppression explosion.

Send your message to us

Graphite Powder Pinewood Derby - Natural Flake Graphite (Expandable Graphite)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches