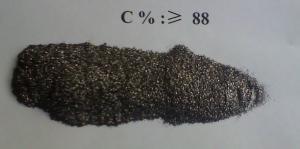

Fine Graphite Powder - Super Crystalline Natural Flake Graphite for Conductivity

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Carbon Content LG

size -200-1000mesh

fixed carbon 94-99%min

moisture 1%max

screen undersize 80%min

Advanced production equipment

The Company has the advanced process of graphite production line ,the domestic first-class could be expanded graphite, flexible graphite sheet production line .It is well –equipped, technologically advanced.

Main products

Main products The Sea Whale brand graphite series products,include : Medium Carbon Graphite ,High Carbon Graphite ,Micro powder Graphite,Expandable Graphite ,Graphite Products. vproduct category The natural flake graphite , Micro powder Graphite , Expandable Graphite ,Graphite coil vNo.1 , The natural flake graphite vTypes: Medium Carbon Graphite ,High Carbon Graphite ,High Purity Graphite vSpecifications :The particle size ranges form 45μm-500μm(325mesh-35mesh),and the carbon content ranges from 85 to 99%.

| Micro powder Graphite Specification description | |||||

| Micro powder Graphite | |||||

| Types F | |||||

| Specifications: The particle size ranges from 10um to 75um. | |||||

| Advantages: Excellent property of crystalline flake graphite, unusual oxidation resistance, self-lubricity, mould ability and adhesively, superior electric and thermal conductivity. | |||||

| Use: Micro powder graphite can be used (1)additive of metallurgical industry.(2)materials of flexible graphite.(3)absorbent materials of battery.(4)additive of lubricant.(5)additive of refractory.Main index of physics and chemistry (Medium-sized) | |||||

| Micronized graphite powder Brand No. | Fixed carbon | Ash | Moisture | Particle size | Inspection Equipment |

| (%)min | (%)max | (%)min | (um) min | ||

| F(-)200mesh | 80-99 | 1.0-20 | 0.5 | 75 | wet sieve |

| F(-)325mesh | 80-99 | 1.0-20 | 0.5 | 45 | wet sieve |

| F(-)400mesh | 80-99 | 1.0-20 | 0.5 | 38 | wet sieve |

| F(-)500mesh | 80-99 | 1.0-20 | 0.5 | 30 | Particle seizer |

| F(-)600mesh | 80-99 | 1.0-20 | 0.5 | 25 | Particle seizer |

| F(-)800mesh | 80-99 | 1.0-20 | 0.5 | 18 | Particle seizer |

| F(-)1000mesh | 80-99 | 1.0-20 | 0.5 | 15 | Particle seizer |

| F(-)1500mesh | 80-99 | 1.0-20 | 0.5 | 10 | Particle seizer |

- Q: What are the hazards of inhalation of graphite dust?

- It must be harmful to human beings! Look at the dictionary of carbon black dust lung disease Description: black carbon pneumoconiosis: long-term inhalation of carbon black dust caused by pneumoconiosis. Carbon black is mainly the quality of easy flying carbon. Although the production has been closed and automated, the phenomenon of dust flying still exists. Therefore, workers who produce and use carbon black may have black carbon pneumoconiosis, the shortest length of onset is 15 years, the longest can be more than 25 years, the clinical symptoms are mild, and the progress is slow, and generally does not affect the ability to work.

- Q: Graphene with graphite powder where to do ah, high carbon content of the?.

- Look at the document, 45 microns will do. Good to buy. Preferably expanded graphite. But then again, if you buy graphite as graphene... The difficulty is not small

- Q: What is the industry standard of graphite powder coating for casting?

- One is purity, that is, the size of impurities, the smaller the better.

- Q: The principle of a graphite missile

- Graphite conducts graphite on the wire to short-circuit the circuit

- Q: For thermal grease skills, the more detailed the better

- If the fins and the metal cover of the CPU are as smooth as mirrors, they will be 100 percent fully exposed to the best thermal conductivity.

- Q: Can graphite be made directly from graphite powder? How about the effect?

- Image, graphite powder, like flour, in order to make bar shaped, such as face and water, you need to add something.

- Q: Antistatic concrete with graphite powder and conductive carbon black, which effect is good?More specific. I don't quite understand

- The better conductivity is graphitized carbon, the higher the degree of graphitization, the better the conductivity. In general, the conductivity of graphite is better than that of black carbon (both of which are of high purity, if not of high purity).

- Q: Graphite and graphite in the end is not a matter I would like to know the graphite and graphite

- Graphite gum APS two, colloidal or semi - colloidal graphite. (a) colloidal graphite, graphite powder from natural or artificial graphite fine powder in water or other media (e.g., alcohol, mineral oil) colloidal suspensions in the form, and can add a few other products (e.g., tannic acid or ammonia) to be stable. Colloidal graphite is usually semi liquid and is used primarily for lubricating products or for its high electrical conductivity. (two) a semi colloidal graphite (i.e., a colloidal suspension of graphite in water or other medium). Semi crystalline graphite can be used to prepare graphite lubricants or to form graphitized surfaces. This class contains only colloidal or semi colloidal suspensions of graphite with graphite as base material in any medium.

- Q: Are graphite and carbon black the same?

- The difference is great, although graphite and carbon black are of the same kind

- Q: What kinds of graphite powder has it? What's the function?

- Its main use focuses on sealing and lubrication, and stone toner is powder, is the basis of other graphite products

Send your message to us

Fine Graphite Powder - Super Crystalline Natural Flake Graphite for Conductivity

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords