Pure Natural Flake Graphite Powder 200mesh - Graphite Powder South Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DESCRIPTION

PURE Natural flake Graphite Powder 200mesh

1.carbon content:80%-95%

2.Size: -200mesh, -300mesh

3.package: 25kg bag

Natural flake graphite powder

TECHINICAL SPECIFICATION

PURE Natural flake Graphite Powder 200mesh

Carbon content: 80%-95%

Size: -200mesh, -100mesh, -300mesh or according to customers requirement

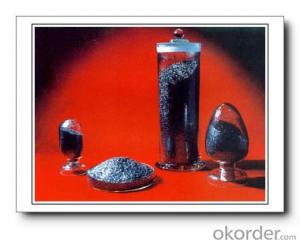

PICTURE

PURE Natural flake Graphite Powder 200mesh

Advantage

PURE Natural flake Graphite Powder 200mesh

Perfect crystallization,thin flake,good flexibility,excellent chemical and physical properties,superior conductivity,self-lubricity and resistance to temperature,corrosion and hot shock,and much more.

Usage

PURE Natural flake Graphite Powder 200mesh

Crystalline flake graphite is widely used as an essential nonmetallic mineral in almost all industries. It can be used as high-quality refractory material or coatings in metallurgical industry, black lead.

- Q: Whether the ordinary graphite powder is sprinkled on the electronic instrument can lead to the malfunction of the instrument

- Graphite powder mainly high pure graphite, graphite powder, nano graphite powder, each is toner has a specific map, if abused, graphite powder will have a certain impact on the letter together, Ruida professional build thermal field | graphite graphite graphite | | isostatic graphite graphite mold, hope this the answer can help to you

- Q: Will dust explosion occur in graphite dust? If you have definite or negative judgment, please share it according to data.

- Any object that is crushed will have a surface energy (internal energy), but the temperature will not increase, so the specific heat will become largerFuel burns because its energy is already full (reaching a point of fire)When the object reaches the ignition point, internal energy = (ignition +273.15) * specific heat capacity

- Q: What is the industry standard of graphite powder coating for casting?

- One is purity, that is, the size of impurities, the smaller the better.

- Q: Method for identifying iron powder, aluminium powder and graphite powder

- They can be used to determine the reaction with acid: the same quality, the same mass fraction of dilute hydrochloric acid solution, and then the three kinds of powder into three kinds of solution, graphite powder and hydrochloric acid reaction observed, iron and aluminum powder and hydrochloric acid hydrochloric acid reaction is slow, can react violently, prove that the nature of the most active aluminum iron, the main component of carbon graphite is the most stable chemical properties.

- Q: Like the wolf, adding graphite powder in the failure of electronic instrument air explosion in aircraft rocket season, really make it

- If you want to hit the plane down, EMP is more practical! Besides, it is also expensive than with stinger!

- Q: Is battery capacitor powder dangerous?

- Will pour into the dry drying workshop, drying after bagging, namely ordinary graphite powder, the carbon content of the finished product is an average of 90%. Use to make pencil cores, graphite electrodes for batteries, lubricant features for cable cars, a dark gray, metallic, opaque, flaky solid.

- Q: The graphite powder production process and the graphite production process are introduced briefly Graphite powder production process, graphite production process, detailed technical parameters where?

- According to the size of the crushed or broken material, the mill can be divided into coarse crusher, middle crusher, fine mill and superfine mill.

- Q: How to measure the iron content in graphite powder?

- Take a certain amount of samples, adding dilute hydrochloric acid, excessive filtering and drying. The quality of the filter residue. By weighing the quality of the sample quality is the quality of minus slag containing iron. With this value divided by the sample quality, the mass fraction of iron.

- Q: Phosphoric acid, two aluminium hydride, with graphite powder and mud

- Some of the key wavelengths off the chemical bond are shown below. The C-N bond is easiest to break, and the C-H bond is the hardest. You can also see that ultraviolet radiation can cause many chemical bonds to break. The activation wave length of some polymers is listed below. The data in the following table show that different polymers have different maximum damage wavelengths, and often the maximum damage wavelength is called the maximum activation wavelength. At this particular wavelength of light, the polymer can crack at the fastest rate.

- Q: Why does the temperature rise when the graphite powder is turned on?

- What is the value of resistance, and this value is not an accurate number, because the graphite powder thickness is not the same, used in different materials and environment, graphite powder, resistance value will be different.

Send your message to us

Pure Natural Flake Graphite Powder 200mesh - Graphite Powder South Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords