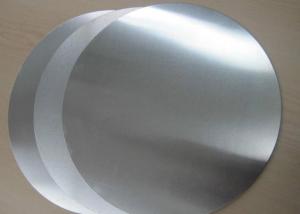

2023 New production High Quality 3003 Alloy Aluminium Circle and Aluminum Disc

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Specification & Description

2.Application :

For Aluminium cookware,pot,pan,stock pots,frypan,reflector of the light

3.Packing Pictures

- Q: How can I make aluminum oxide?

- It turns out to be surprisingly difficult to do, because aluminum forms a skin of oxide which retards further oxidation. One way might be to react aluminum with sulfuric acid, getting aluminum sulfate in solution. Treat this with barium hydroxide; barium sulfate will precipitate out, leaving aluminum hydroxide in solution. Dry this and heat it, driving off the hydroxide as water and leaving aluminum oxide. I haven't tried this, so cannot guarantee that it will work.

- Q: Are aluminum sheets suitable for automotive wheels?

- Yes, aluminum sheets are suitable for automotive wheels. Aluminum offers several advantages such as being lightweight, corrosion-resistant, and providing better heat dissipation. These qualities make aluminum sheets a popular choice for manufacturing automotive wheels as they contribute to improved fuel efficiency and overall performance of the vehicle.

- Q: What are the different finishes available for aluminum sheets?

- Some different finishes available for aluminum sheets include mill finish, brushed finish, embossed finish, anodized finish, and painted finish.

- Q: What are the various color and pattern options for aluminum sheets?

- <p>Aluminum sheets are available in a wide range of colors and patterns to suit various applications and aesthetic preferences. Colors can include silver, white, black, bronze, and many other shades. Patterns can range from simple matte or gloss finishes to more complex textures like wood grain, stone, and brushed metal effects. Some aluminum sheets also feature anodized finishes for enhanced durability and color vibrancy. Custom colors and patterns can be created through specialized coating processes, allowing for a high level of personalization in design and construction projects.</p>

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: The real bumper/ reinforcement bar that is behind the plastic bumpers. Magnet don't stick to it and it don't rust which both types of metal are pretty much like that.

- Aluminum, stainless is too expensive and not ductile enough to be made into bumpers, especially of that complexity. As far as the magnetism, the magnet would only stick to low nickel stainless and its not likely that they would use 308 on a consumer vehicle.

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets depends on various factors, such as the alloy, thickness, and temper of the sheet. However, a general guideline for the minimum bend radius for aluminum sheets is typically around 1 to 1.5 times the material thickness. For example, if you have a 1mm thick aluminum sheet, the minimum bend radius would be around 1 to 1.5mm. It is important to note that this is just a general guideline, and the specific bend radius may vary depending on the specific application and requirements. It is advisable to consult with a professional or reference material specifications for precise bend radius recommendations for a specific aluminum sheet.

- Q: This question asks for a method to measure the thickness of an aluminum sheet.

- <p>To determine the thickness of an aluminum sheet, you can use a micrometer or a caliper, which are precise measuring tools. Place the sheet on a flat surface and measure from one side to the other at multiple points to account for any inconsistencies. Alternatively, you can use an ultrasonic thickness gauge, which is especially useful for non-contact measurements. For a quick estimate, a simple ruler can give you a rough idea, but for high precision, specialized tools are necessary. Always ensure the measuring device is calibrated and used correctly to get accurate results.</p>

- Q: Are aluminum sheets suitable for chemical processing equipment?

- Under certain conditions, chemical processing equipment can utilize aluminum sheets. Aluminum demonstrates good resistance to a variety of chemicals, including acids and alkalis. It exhibits exceptional resistance to corrosion in acidic surroundings like hydrochloric acid and sulfuric acid, as well as alkaline solutions such as sodium hydroxide. However, it is crucial to acknowledge that aluminum is not universally suitable for all chemical processes. It is not advisable to employ it in applications involving potent oxidizing agents like nitric acid or chromic acid, as these substances can swiftly corrode aluminum. In addition, aluminum is incompatible with certain organic solvents and can react with them, leading to equipment degradation or malfunction. In certain situations, aluminum can be employed in chemical processing equipment by employing protective coatings or linings to bolster its resistance against specific chemicals. This approach can enhance its longevity and broaden its range of applications. In conclusion, although aluminum sheets can be appropriate for chemical processing equipment in numerous cases, it is imperative to carefully evaluate the specific chemicals and operating conditions involved to ensure compatibility and steer clear of potential corrosion or malfunction issues.

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

2023 New production High Quality 3003 Alloy Aluminium Circle and Aluminum Disc

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords