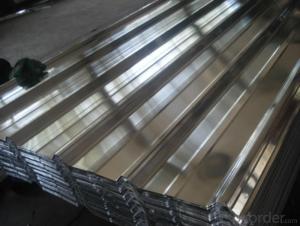

Aluminum 4 X 8 Sheets - Corrugated Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

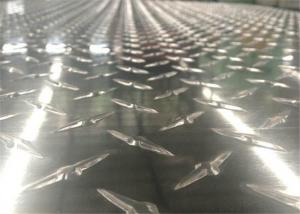

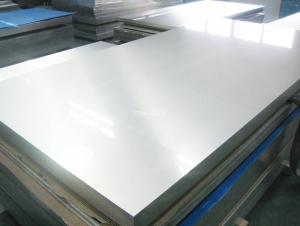

Corrugated Aluminum Plate in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

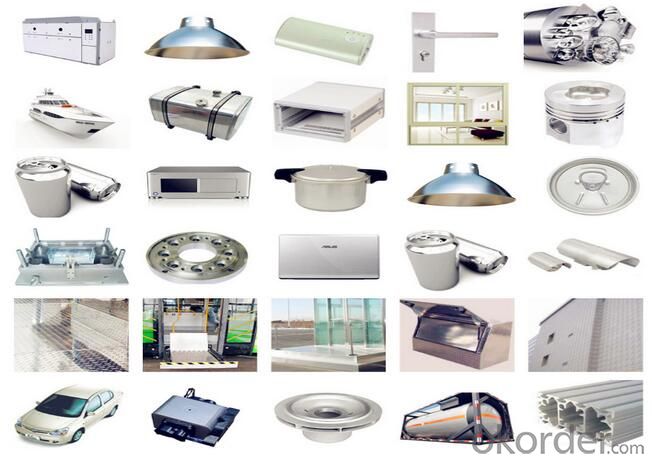

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: Can aluminum sheets be used for furniture manufacturing?

- Yes, aluminum sheets can be used for furniture manufacturing. Aluminum is a versatile material with several advantageous properties that make it suitable for furniture production. It is lightweight, durable, corrosion-resistant, and can be easily molded into various shapes and sizes. Additionally, aluminum has a sleek and modern aesthetic, making it a popular choice for contemporary furniture designs. Aluminum sheets can be used to create frames, legs, and other structural components for different types of furniture, including chairs, tables, shelves, and cabinets. The versatility and durability of aluminum make it a viable option for furniture manufacturing, especially for outdoor or industrial furniture that requires resistance to harsh weather conditions or heavy use.

- Q: Are the aluminum sheets suitable for manufacturing architectural roof systems?

- Yes, aluminum sheets are suitable for manufacturing architectural roof systems. Aluminum is lightweight, durable, corrosion-resistant, and easy to work with, making it an ideal material for constructing roof systems in architectural projects.

- Q: How can I make aluminum oxide?

- It turns out to be surprisingly difficult to do, because aluminum forms a skin of oxide which retards further oxidation. One way might be to react aluminum with sulfuric acid, getting aluminum sulfate in solution. Treat this with barium hydroxide; barium sulfate will precipitate out, leaving aluminum hydroxide in solution. Dry this and heat it, driving off the hydroxide as water and leaving aluminum oxide. I haven't tried this, so cannot guarantee that it will work.

- Q: i want to a material which is similar in properties like aluminium which has similar casting properties and easily available.

- Aluminum is lousy for casting because it shrinks and tears. However you can add about 2% finely divided steel and get a useable alloy. It is better to use what everybody else uses: pot metal. Any junk yard can provide an endless supply of carburetor bodies which you can melt at fairly low temperatures and get nice strong castings. If you can locate some ancient floppy drives or dot matrix printers you will get a prettier alloy.

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Yes, aluminum sheets can be anodized for aesthetic purposes. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This layer can be dyed in various colors, creating a wide range of aesthetic options. Anodized aluminum sheets are popular in architectural applications, such as building facades, as they provide a durable and visually appealing finish. The anodized layer also enhances the corrosion resistance and wear resistance of the aluminum, making it suitable for both indoor and outdoor uses. Additionally, anodized aluminum sheets can be further processed through techniques like etching or laser engraving, allowing for the creation of intricate designs and patterns.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: How does the surface treatment of aluminum sheet affect its appearance?

- The appearance of aluminum sheet is greatly influenced by its surface treatment. Natural aluminum has a shiny and reflective surface, which can be improved or modified through different surface treatments. One popular surface treatment for aluminum sheet is anodizing, which involves the creation of a protective oxide layer on the surface through an electrochemical process. This treatment offers a wide range of colors and finishes, ranging from vibrant and opaque to translucent and metallic. Anodized aluminum sheets have a sleek and modern look, making them commonly used in architectural and decorative applications. Another option for surface treatment is painting or powder coating. These processes involve applying a layer of paint or powder onto the surface of the aluminum sheet. This treatment allows for customization in terms of color, texture, and finish. Painted or powder-coated aluminum sheets can have a smooth and glossy appearance or a textured and matte finish, depending on the desired outcome. This treatment is frequently utilized in industries like automotive, aerospace, and construction, where aesthetics and durability are important. Additionally, aluminum sheets can undergo mechanical surface treatments like brushing or polishing. Brushing involves creating parallel lines on the sheet's surface using abrasive pads, resulting in a brushed or satin finish. This treatment gives aluminum sheets a contemporary and industrial look. On the other hand, polishing involves buffing the surface to a high gloss and mirror-like finish. This treatment is often used for decorative purposes, such as in the production of jewelry or household items. In conclusion, the surface treatment of aluminum sheet plays a crucial role in determining its appearance. Whether it is anodizing, painting, powder coating, brushing, or polishing, each treatment offers a distinct visual effect that can enhance the aesthetic appeal of the aluminum sheet for specific applications and industries.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity and low density, making it an ideal material for cryogenic applications. It can withstand extremely low temperatures without losing its structural integrity or experiencing significant thermal expansion. Additionally, aluminum has good corrosion resistance and can be easily fabricated into various shapes and sizes. These properties make aluminum sheets commonly used in cryogenic systems, such as cryostats, superconducting magnets, and liquid nitrogen storage tanks.

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

- Q: Can aluminum sheets be used for flooring?

- Yes, aluminum sheets can be used for flooring. Aluminum is a lightweight and durable material that is resistant to corrosion, making it a suitable choice for various flooring applications. Aluminum sheets are often used in industrial, commercial, and residential settings, including warehouses, garages, kitchens, and outdoor spaces. They offer good strength, easy installation, and low maintenance. Additionally, aluminum flooring can provide a sleek and modern appearance to any space. However, it is important to consider factors such as thickness, finish, and the specific requirements of the flooring project before selecting aluminum sheets.

Send your message to us

Aluminum 4 X 8 Sheets - Corrugated Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords