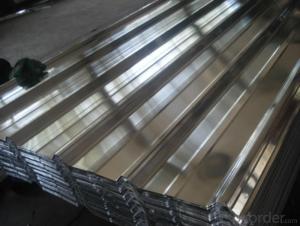

Direct Casting Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Direct Casting Aluminum Plate in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

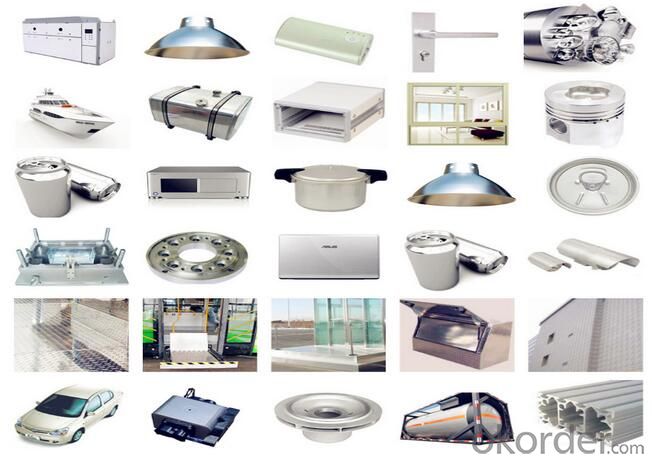

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

Packing

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q:How do aluminum plates open holes?

- The opening of the aluminum plate is a relatively simple process,You can do that with a micro electric device like an electric drill or a grooving machine

- Q:Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable. Aluminum is a highly recyclable material, and the recycling process for aluminum sheets is relatively simple and efficient. Recycling aluminum sheets involves melting the metal down and reforming it into new sheets or other aluminum products. The recycling process for aluminum requires considerably less energy compared to the production of new aluminum, making it an environmentally-friendly option. Additionally, recycling aluminum sheets helps conserve natural resources and reduces the amount of waste sent to landfills. Therefore, it is encouraged to recycle aluminum sheets whenever possible to contribute to a more sustainable and eco-friendly future.

- Q:Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Yes, aluminum sheets are suitable for manufacturing electronic enclosures. Aluminum is a popular choice for electronic enclosures due to its excellent combination of strength, durability, and lightweight properties. It offers good electrical conductivity, making it suitable for dissipating heat generated by electronic components. Additionally, aluminum sheets can be easily shaped, formed, and machined to meet the specific requirements of electronic enclosures, allowing for customization and flexibility in design. Its corrosion resistance properties also make it suitable for protecting electronic devices from environmental factors. Overall, aluminum sheets provide an ideal material solution for manufacturing electronic enclosures.

- Q:Can aluminum sheets be painted after installation?

- After installation, it is indeed possible to paint aluminum sheets. Aluminum, being a highly versatile and durable material, can be painted for the purpose of improving its appearance or harmonizing it with the surrounding environment. However, it is crucial to adequately prepare the surface before painting in order to ensure that the paint adheres well and lasts long. This typically involves cleaning the surface, eliminating any dirt or debris, and applying a suitable primer to enhance paint adhesion. Once the surface is prepared, various types of paint can be used on the aluminum sheet, such as acrylic, oil-based, or epoxy paint. To achieve the best results, it is advisable to seek guidance from a professional painter or carefully follow the instructions provided by the paint manufacturer.

- Q:How do you clean aluminum sheets?

- To clean aluminum sheets, you can follow a few simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum sheet. You can use a soft brush or cloth to gently sweep away any particles. 2. Prepare a cleaning solution by mixing a mild detergent or dish soap with warm water. Avoid using strong chemicals or abrasive cleaners as they can damage the aluminum. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum sheet. Make sure to cover the entire surface, paying extra attention to any stains or spots. 4. If there are stubborn stains or marks on the aluminum, you can use a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner to a soft cloth and rub gently on the affected area until the stain is removed. 5. Rinse the aluminum sheet thoroughly with clean water to remove any soap residue. This step is essential to prevent any build-up or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Make sure there is no moisture left as it can cause water spots or corrosion over time. 7. For added shine and protection, you can apply a thin layer of aluminum polish or wax. This will help to restore the luster and protect the aluminum from future tarnish or oxidation. It is important to note that the cleaning method may vary depending on the type of dirt or oxidation on the aluminum sheet. Always read and follow the manufacturer's instructions for specific cleaning recommendations.

- Q:i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q:is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

- Q:A 15.1 g aluminum block is warmed to 53.2 °C and plunged into an insulated beakercontaining 32.6 g of water initially at 24.4 °C. The aluminum and the water are allowed to cometo thermal equilibrium.Assuming that no heat is lost, what is the final temperature of the water and aluminum?

- To solve this problem, you need the heat capacity of water and Al, I know off hand the heat capacity of water but you'll need to look it up for Al. From the problem, you know that the heat given up as the aluminum cools is gained by the water heating up. As there is no phase change, the heat gained (or lost) is mass * heat capacity * temperature change energy gained by water = energy lost by Al. Let Tf be the final temperature of the Al and water. 32.6 g * 4.18 J/gK * (Tf - 24.4C) = 15.1 g * heat capacity of Al * (53.2 C - Tf) Solve for Tf. Because there is almost twice as much water as Al and water has a higher heat capacity than Al, the temperature will be closer to 24.4C than it is to 53.2C

- Q:5052 can aluminum plate be machined with laser cutting machine?

- Can cut, thickness less than 5, cutting edge without burr, not melt.

- Q:I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- The cast aluminium pot are used in families, hotels and for any needs. They are very safe to cook.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Direct Casting Aluminum Plate in Different Corrugation Profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords