0.4mm 1050 1060 3003 thin aluminum strip is suitable for blinds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Blinds are a kind of soft decoration for new homes. Now new buildings are basically used for decoration. "Aluminum alloy blinds" are a widely used type of curtains, made in the shape of blinds. Aluminum alloy blinds are mainly made of aluminum alloys that are not easy to rust.

Commonly used aluminum strip alloys for blinds include 1050, 1060, 3003, 3004, 3104 and 5052. These alloys are widely used in blinds because they have good performance and applicability.

Performance advantages of aluminum strips for blinds:

1. Lightweight characteristics: easy to install, use and carry, reducing the burden on building structures.

2. Corrosion resistance: an aluminum oxide film is formed on the surface to effectively resist wind and rain erosion and oxidation corrosion.

3. Good processability: easy to process into various shapes and sizes to meet diverse design needs.

4. Aesthetics: The surface is smooth and shiny, with good decorative effect and supports personalized surface treatment.

Aluminum strip specifications:

| Alloy | 1050 1060 3003 5052 etc |

| Temper | H14, H24, H16, etc. |

| Thickness | 0.1-0.5mm |

| Width | Common widths are 16mm, 25mm, 50mm, etc. The specific size can be customized according to the specifications of the blinds. |

| Surface treatment: | (1) Anodizing: Improves corrosion resistance and increases color options. (2) Coating treatment: Apply weather-resistant paint to enhance decorativeness. (3) Brushed, frosted treatment: Provides a textured surface. |

| Quality | No rust, oil stains, rolling marks, edge damage, flaring, dents, holes, broken wires, scratches |

| Application | blinds, window curtains, etc. |

| Packaging | Export wooden pallets, kraft paper. |

| MOQ | 1-3 tons |

| Delivery time | 7-15 days after payment |

Application scenarios:

Aluminum strip blinds are widely used in various buildings and home environments, such as offices, residences, schools, hospitals, etc. They not only provide good shading and ventilation functions, but also increase the beauty and practicality of the building.

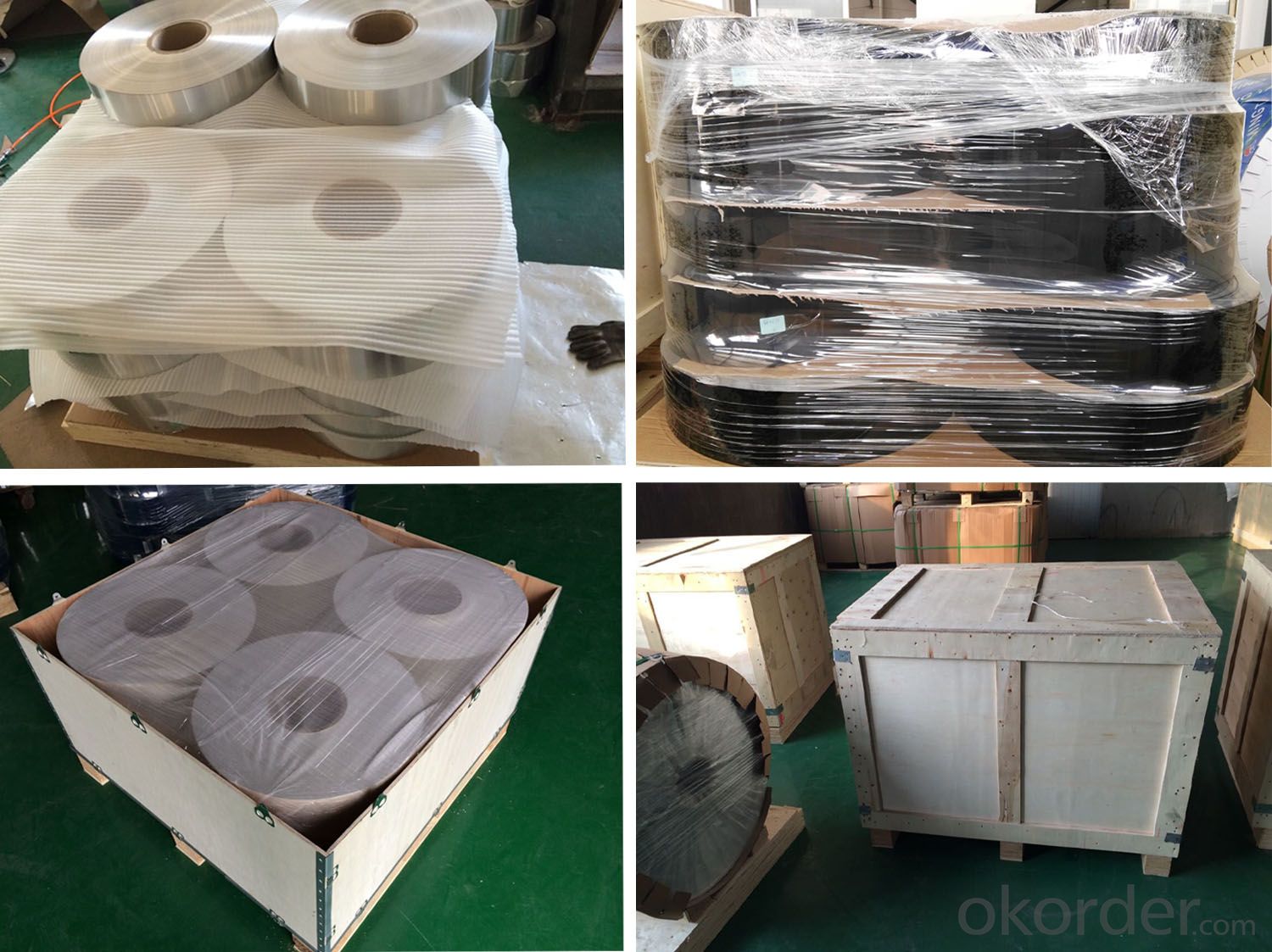

Packing:

(1) Standard seaborne export packaging, wooden pallets, with plastic protection coils and sheets;

(2) 15-20 tons can be loaded into a 20-foot container. We try to use 20-foot containers. The sea freight is much cheaper than 40-foot containers.

(3) Other packaging can be made according to customer requirements.

(4) The packaging is very strong, with 3 layers, thick fiber, foam, plastic. The bottom is a wooden pallet. You can see the detailed packaging information below.

FAQ:

Q1: How to ensure quality?

A1: Factory test certification is provided with shipment, third-party inspection can be provided

Q2. What are your company's main products?

A2: Our main products are aluminum, aluminum plate, aluminum foil, aluminum strip, patterned plate, automotive plate, marine grade aluminum plate, household foil, hydrophilic aluminum foil, bottle cap material, etc.

Q3: Where is your factory?

A3: Our company's processing center is located in Xin'an Industrial Assemble Region, Luoyang, Henan Province, China

Q4: What are the advantages of your company?

A4: We have many professionals, technicians, more competitive prices and best after-sales service than other companies.

Q5: How is your price?

A5: Our price is very competitive. If you are interested in our products, please feel free to contact us at sales @ alummc . com.

Aluminum strip products have a wide range of market uses. Our company has many types of equipment, including multiple longitudinal shearing equipment, complete equipment models, and products can cover all alloy series. The product supply forms are diverse and can meet all customer needs. The strip thickness of our company ranges from 0.08mm-10mm, and the width ranges from 12mm-2600mm, and coils are supplied.

- Q: 25 square metres of aluminium wire. Can you bring up 4 sets of two air conditioners?

- According to the load calculation, 4 sets of two air conditioners, as long as the wire reached 8 square, you can drive. Your 25 wire can drive. But it is recommended that you use copper wire as a guide wire. The quality and service life of the copper wire is much better than that of the aluminum wire.

- Q: Is it possible to use aluminum strips for exterior trim applications?

- <p>Yes, aluminum strips can be used for exterior trim. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor use. Aluminum trims are low maintenance and can withstand various weather conditions without rusting. They are also available in a variety of colors and finishes, allowing for flexibility in design. However, it's important to ensure proper installation and use high-quality materials to guarantee longevity and performance.</p>

- Q: Is it possible to utilize aluminum strips in constructing a rainscreen wall system?

- <p>Yes, aluminum strips can be used to create a rainscreen wall system. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It allows for proper ventilation and drainage behind the cladding, which helps prevent moisture damage and thermal stress. When designing a rainscreen system with aluminum strips, ensure that the installation follows building codes and standards, and that the strips are properly spaced and sealed to maintain the system's effectiveness.</p>

- Q: This question asks for an overview of the various types of aluminum strips that are available in the market.

- <p>Aluminum strips are available in various types based on their thickness, width, alloy composition, and surface finish. Common types include: 1) Plain aluminum strips, which are general-purpose and used in packaging and construction. 2) Embossed aluminum strips, used for decorative purposes or to enhance grip. 3) Anodized aluminum strips, which offer improved corrosion resistance and are used in automotive and aerospace applications. 4) Heat-treated aluminum strips, which have enhanced strength and are used in structural components. 5) Coated aluminum strips, which have a protective or decorative layer applied, used in food packaging and electronics. 6) Foil strips, which are very thin and used in food packaging, pharmaceuticals, and thermal insulation. Each type has specific applications and properties that make it suitable for particular industries and uses.</p>

- Q: Is it possible to use aluminum strips to repair a wall that has been damaged by water?

- <p>Yes, aluminum strips can be used to cover a wall damaged by water, but it's not the most effective solution. Aluminum strips are typically used for decorative purposes or as a protective layer in certain applications. For water-damaged walls, it's better to first address the underlying issue, such as fixing leaks or improving drainage. Then, repair the damaged area with appropriate materials like drywall or plaster, followed by painting or other finishing touches. Using aluminum strips without proper repair may lead to further damage or an unsightly appearance.</p>

- Q: Is it possible to use aluminum strips as a material for exterior siding on a building?

- <p>Yes, aluminum strips can be used for siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and comes in various colors and styles, making it a popular choice for residential and commercial buildings. It also has good resistance to harsh weather conditions and does not rot or warp, which are common issues with wood siding.</p>

- Q: Is there any health risk associated with the use of aluminum in food packaging?

- <p>There are some concerns about the use of aluminum in food packaging due to its potential to leach into food, especially when in contact with acidic foods. Aluminum exposure has been linked to neurological disorders, including Alzheimer's disease, although the evidence is not conclusive. The World Health Organization states that while there is no clear risk from dietary aluminum, further research is needed. It's important to note that aluminum is naturally present in many foods and drinking water, and the body can only absorb a small amount of aluminum from food packaging. Most aluminum exposure comes from natural sources, not from packaging.</p>

- Q: What are the drawbacks or negative aspects associated with the use of aluminum strips?

- <p>The disadvantages of using aluminum strips include their relatively low strength compared to some other metals, making them less suitable for heavy-duty applications. They can also be prone to corrosion, especially in humid environments, which can reduce their lifespan. Additionally, aluminum strips may not be as rigid as other materials, leading to potential issues with structural integrity. Lastly, while aluminum is recyclable, the recycling process can be energy-intensive, and the environmental impact of its production, including greenhouse gas emissions, should be considered.</p>

- Q: What factors should be considered to determine if an aluminum strip is suitable for a specific application?

- <p>To determine if a certain type of aluminum strip is suitable for your application, consider the following factors: mechanical properties such as strength and ductility, corrosion resistance, thermal conductivity, and electrical conductivity. Assess the strip's dimensional tolerances and surface finish to ensure they meet your requirements. Check if the strip's formability and weldability align with your manufacturing processes. Also, consider the strip's weight and cost-effectiveness. It's advisable to consult with a material scientist or supplier who can provide specific recommendations based on your application's unique needs.</p>

- Q: What is the standard thickness for aluminum strips and what is it commonly used for?

- <p>The thickness of aluminum strips can vary widely depending on their application, but common thicknesses range from 0.005 inches (0.127 mm) to 0.5 inches (12.7 mm). Aluminum strips are typically used in various industries such as construction, automotive, aerospace, and packaging. They are utilized for manufacturing parts, creating foils, and in applications requiring lightweight, strong, and corrosion-resistant materials.</p>

Send your message to us

0.4mm 1050 1060 3003 thin aluminum strip is suitable for blinds

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 T

- Supply Capability:

- 200 T/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords