Light Gauge Aluminium Foils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Light Gauge Aluminium Foils for Different Usages

Light Gauge Aluminium Foils for Different Usages are widely used in cigarette package, aseptic package, pouches, sachets.

Light Gauge Aluminium Foils for Different Usages meet the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

We have very strict inspection management. Test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Light Gauge Aluminium Foils for Different Usages

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

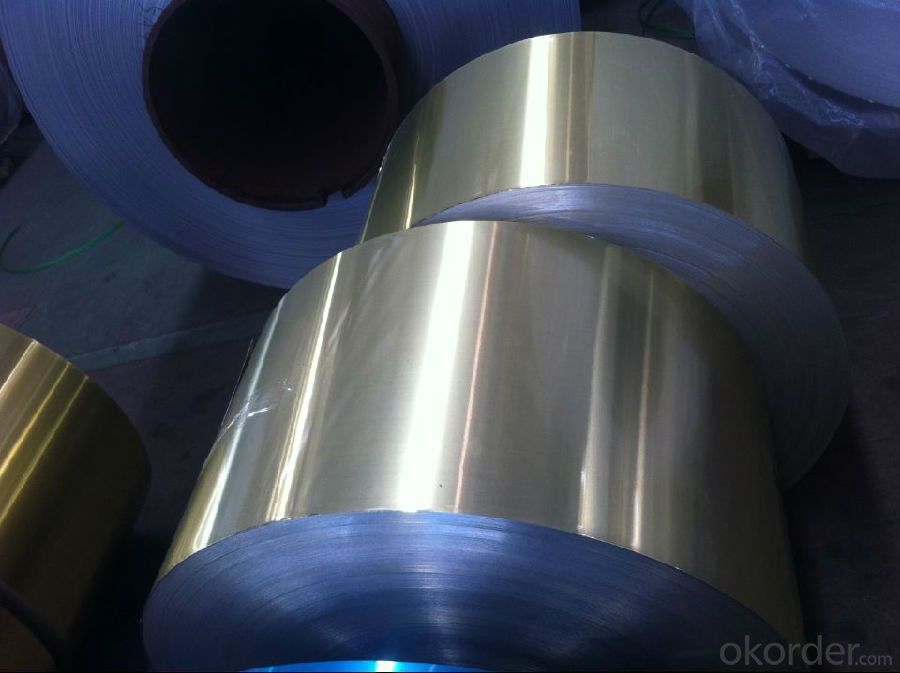

3. Light Gauge Aluminium Foils for Different Usages Images

4.Specification of Light Gauge Aluminium Foils for Different Usages

Alloy | 8011/1235/8079 |

Temper: | O |

Thickness: | 0.006mm-0.009mm (+/-6%) |

Width: | 200mm-1650mm |

Standard: | GB/T3198/ASTM-B209/EN546 |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Aluminum foil tape insulation principle, why insulation?

- The air conditioner foil is a special material for the heat exchanger fin of an air conditioner, and an early air conditioner foil is a plain foil. In order to improve the surface properties of the plain foil, an anticorrosive inorganic coating and a hydrophilic organic coating are applied before forming to form hydrophilic foil. At present, hydrophilic foil accounts for 50% of the total amount of air conditioning foil, and its use ratio will be further improved. There is also a hydrophobic foil, so that the fin surface has hydrophobic function, prevent condensation water adhesion. Because of hydrophobic foil, the technology of improving surface defrosting needs to be studied further.

- Q:What's the specialty of aluminum strip rolling?

- I don't know what raw material this enterprise produces, which is related to the process. The state has the aluminum industry cleaner production evaluation index system (issued by the Ministry of industry), the clean production standard of alumina industry and the clean production of electrolytic aluminum industry

- Q:How does the excavator aluminum belt turn in place?

- When the mechanical steering, separate driving force on the side of the track of unilateral, separation power can not overcome the ground friction due to the relative motion in a static state; and the other side of the track with power in motion, its trajectory is a circle, this is equivalent to us so we use your compasses to draw a circle; see mechanical steering.

- Q:What gas is best for welding aluminum strip?

- If you are using the gas, liquefied gas gun can be used separately burning liquefied petroleum gas welding, then burning gas is liquefied gas, but this time need to use low temperature welding wire, such as the WEWELDING M51 with WEWELDING M51-F solder welding wire.

- Q:Is it good to drive a wheeled excavator or an aluminum belt?

- Wheeled as if driving a car, the aluminum belt seems to open tanks.

- Q:What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- Not appearing in spots. Suitable for mirror surface, spray coating. Hot rolling is more expensive than cold rolling

- Q:What effect does the aluminum pulley bring to the belt?

- The timing belt pulley is aluminum. Friction wheel? Not seen with aluminum, may be too hot, aluminum easy adhesion, resulting in increased friction

- Q:What's the difference between aluminum strip and aluminum alloy?

- Aluminum strip is an aluminum processing product. It is produced by pressure processing (rolling) of aluminum alloy. Aluminum alloy is a broad term, generally referred to as aluminum alloy.

- Q:What is the best capacitance for an aluminum ribbon tweeter?

- You can go to your problem related professional website forum to see, there gathered a lot of professionals, you can solve the problem.

- Q:Which is the best aluminum alloy belt?

- Of course, choose Jiangsu Yang Dong Aluminum Co., Ltd., specializing in the production of aluminum and aluminum alloy, high precision machining, spot warehousing, product sales, technical consulting in one of the large-scale comprehensive import and export of aluminum materials spot sales.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Gauge Aluminium Foils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords