Borosilicate Float Glass 4.0 for Building Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

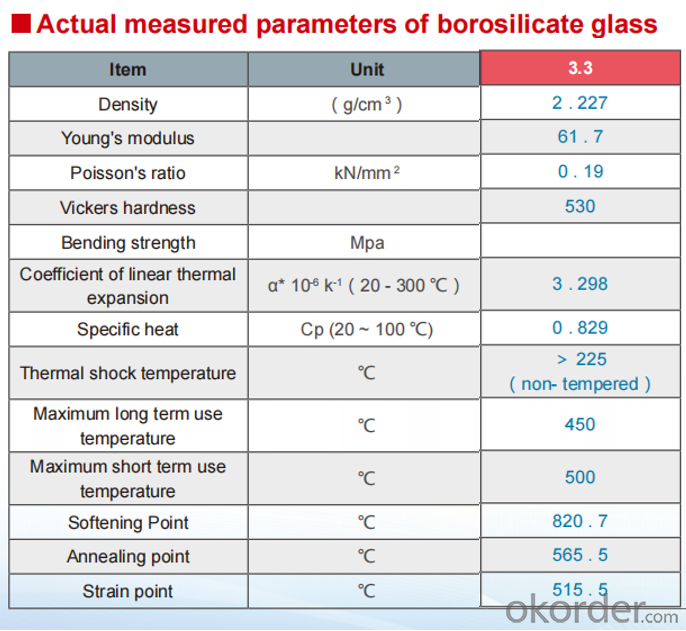

Borosilicate glass, also known as high borosilicate glass, is known as the "King of Glass".

Its main component is about 80% silicon oxide and about 10% boron oxide.

At this time, both silicon oxide and boron oxide can basically form microtetrahedrons.

Framework (the more the micro tetrahedral framework in the glass is, the greater the ionic bond force will become, contributing to a more stable performance), the other is about 5% of stable oxide and about 5% of flux.

2. Main Features:

3. Advantage:

Float Glass is superior in quality when compared to other flat glass and has the unique characteristics of excellent surface finishing, flatness, uniform thickness, high optical quality and bright appearance.

The float process was invented in 1952.

Float technology has rapidly replaced plate and sheet facilities worldwide in recent decades.

Float glass derives its name from the float process used where the molten glass floats on the top of molten tin.

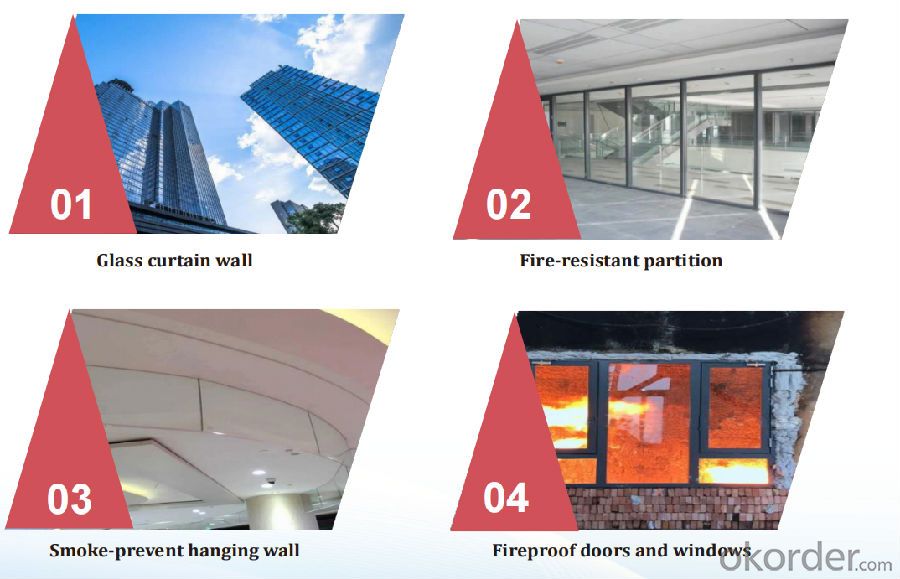

4 . Application Area:

Can be used in fireproof curtain walls, partition walls, platforms, day lighting roofs, smoke-proof vertical walls, railings, doors and windows, elevator shafts, rail transit platform screen doors, rail locomotive doors and windows and other fields.

Equipped with water spray, it can be used to replace Class A insulation type fireproof glass system, which can be widely used in building atrium, pedestrian street fireproof glass and building fireproof partition.

5. Company Brief:

6. Packing & Shipping:

All the glass will pack in strong export plywood crates, and load in container strong firmly, to make sure safety delivery.

- Q: How do you make the glass, please? What is the raw material?

- When you look for information, the proportion of raw materials is very important.

- Q: What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- First of all, you know what zircon sand is[g o], also known as zirconium sand zircon sand, zircon, is a kind of zirconium silicate (ZrSiO4) as the main mineral composition. Zircon sand pure colorless transparent crystal, often because of quantity and species of different origin and different impurities dyed yellow, orange, red and brown color, crystal structure belongs to tetragonal, a square pyramidal column, the proportion of 4.6 to 4.71, the proportion of the variation with composition and sometimes altered state with zirconium stone incomplete cleavage, uniform Mohs hardness of 7 to 8, the refractive index of 1.93 to 2.01, with the melting point of impurities in different 2190~2420 DEG C wave. The main chemical composition is ZrO2, SiO2, and a small amount of impurities such as Fe2O3, CaO, AI2O3 and so on. The theoretical composition of zircon sand is ZrO2:67.1%; SiO2:32.9%. It is the only compound in the ZrO2-SiO2 system. But natural zircon sand contains only about 57~66%ZrO2.

- Q: Ask the glass making processWhat kind of material is the glass made of? What material is good?

- Glass: a liquid material is transparent, forming a continuous network structure in the melt, silicate nonmetalmaterials cooling process viscosity increases gradually and hardening without crystallization. The main ingredient is silica. Widely used in building, but to every wind light.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Ceramic crystallization: glass ceramic composite board is the product of "three in one" of glass, ceramic and stone craft. It combines the glass melting process, ceramic brick molding and crystallization sintering process, stone polishing, cutting process as a whole. In short, microcrystalline glass frit is special stalls shop in the special ceramic tile on the roller kiln sintering crystallization, after polishing and cutting timber.

- Q: What are the anticorrosive materials for glass fiber reinforced plastic?

- Dead work:Before the construction, make sure that the cement ground is completely dry and the foundation is smooth, and then the bottom oil brushing work can be done.Preparation of glass fiber reinforced plastic raw materials and construction equipment.

- Q: What is the raw material of glass? How is it converted to glass?

- Melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters

- Q: What is the raw material of glass glue?

- The common glass glue equipment are as follows: 1.JMSFYF stainless steel reactor series production 2.JMSNHZ series of glass glue silicone kneading machine series 3.JMSXJB planetary mixer series 4.JMSQLF series 5.JMSDLH series strong dispersion mixer hybrid machine series mainly plastic equipment.

- Q: There are several ways of heating the industrial drying tunnel furnace and are different from each other?

- The utility model has the advantages of long service life and high reliability. The heater is made of special electric heating material, and the design power load is reasonable, and the heater adopts multiple protection, so that the safety and the service life of the heater are greatly increased.

- Q: Why is the process of glass toughened always broken?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: Failure reasons and solutions of insulating glass.

- The production of hollow glass raw material quality; key factors affect the service life of hollow glass sealant is ageing resistance and desiccant adsorption capacity, and the determining factor is the performance of sealant. Because no matter how much the desiccant adsorption capacity, inside the hollow glass after a certain limit, when the hollow glass desiccant completely saturated, again good desiccant also unable to water vapor adsorption, then the hollow glass is invalid. Only when the sealant has good sealing performance, moisture permeability coefficient is low, the amount of water vapor into the hollow glass rarely, and keep this state, only rarely can guarantee the hollow glass desiccant inside gas drying, so as to ensure the effect of hollow glass.

Send your message to us

Borosilicate Float Glass 4.0 for Building Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 kg

- Supply Capability:

- 100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches