Safety Clear Tempered Laminated Glass Factory Price For stairs/floor/balustrade Glass

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

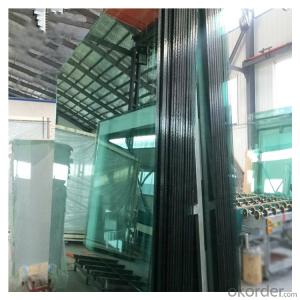

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

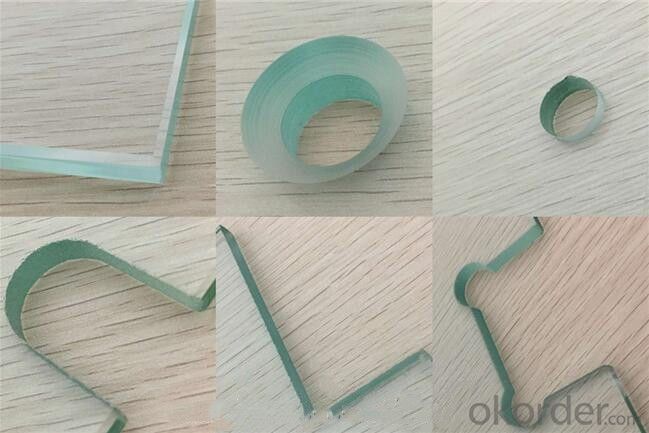

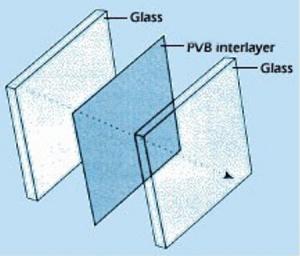

Laminated Glass

Laminated glass is composed of two or more pieces of glass, sandwiched between a layer or multiple layers of organic polymer intermediate film, through special high temperature precompression (or vacuum) and high temperature and high pressure process, so that the glass and intermediate film permanent bonding as one of the composite glass products.

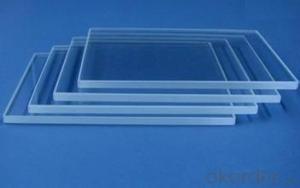

Specification

Single Layer Glass Thickness: 3-25mm

Max. Size: 3000*16000mm

Min Size: 100x300mm Interlayer: PVB, SGP, EVA, Sefar, Decoration Film, mesh etc.

Character:

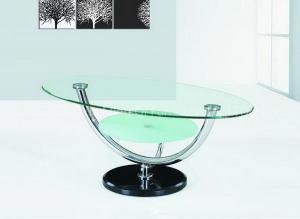

A glass floor is a stunning, dramatic addition to any interior space. Not only does our glass flooring offer aesthetic appeal, but it also allows for light to flow into the space below. The unique benefits of CNBM glass flooring continue with its superior, rigorously tested framing system and its exceptional engineering support and design flexibility. With a beauty and simplicity that can’t be matched, Glass Flooring Systems’ interior system is the perfect solution for any glass-flooring project.

Our triple-laminated glass assembly is engineered for passive redundancy with panels that are fabricated using three layers of low-iron, tempered glass with structural PVB, SGP interlayers. Our structural glass delivers exceptional safety and design flexibility, with the top layer consisting of a safe, non-slip surface that allows light to filter into the space below. This layer can also serve as a form of artistic expression, with dozens of patterns, textures, and finishes that meet or exceed the ASTM safety standards. The role of the interlayers is to bond the layers of glass together to assure the safety and structural integrity of every glass flooring system we produce.

Advantage:

Our glass-flooring system comes standard with a variety of innovative features and options that give it distinct advantages over its competitors:Low-iron glass is standard with all our glass-flooring products;If you need, we can also provide proprietary 6063-T6 aluminum extrusions that produce crisp, clean profiles;Fully tested, anti-slip textures;Pre-engineered and custom sizes for ease of integration;

Packing and Shipping:

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- The main raw material for making glass!! Simply means that the silicon containing sand, ordinary sand containing silicon. Generally, the sand with more silicon content is the good material for making glass. The technology of glass has been developed for more than 5000 years. It was not until twentieth Century that glass became an industrial material and developed rapidly.

- Q: What is the difference between white float glass and ordinary float glass?

- Ultra white is generally used in solar panels, raw materials, aluminum content higher

- Q: What materials do we need to make glass septic tanks?

- 9., the product covers only 60 ~ 80% of the brick and concrete septic tank, which saves land and improves the flexibility of site selection.10., the comprehensive cost is low, and the overall cost is more economical compared with the brick and concrete septic tank.

- Q: What are the raw materials of glass fiber reinforced plastic?

- If they are bonded together with synthetic resins, they can be made of rigid products of a fixed shape, bearing both tensile and flexural, compressive, and shear stresses.

- Q: How to seal the glass fiber reinforced plastic mould?

- Rubber pad seals are thickness, will be relatively increased parting surface gap, for complex, not good concave convex surface, uneven surface, you can use ordinary fastening before playing glass glue or fastening hot melt gun hit again. It can be divided into surface on floor wax coat material brush, then fastening glass steel mold.

- Q: What is the ratio of raw materials for glass mildew proof powder?

- Coconut shell plant essence ("compendium") from endocarp for palm plants in coconut. Coconut palm in plant form. The chemical composition of coconut shell containing 0.61% ash, 36.51% lignin, cellulose 53.06%, pentosan (29.27% total). Cellulose containing 20.54% pentosan, principal components in the ash and koh.

- Q: Does anyone know iPhone's toughened glass production process? Thank you

- The first special glass raw materials used for Corelle Corning, Gorilla Glass or AGC Dragontrail Glass (Asahi; if you need a AR antireflection coating processing, processing)

- Q: What is acrylic material?

- Acrylic properties;1. excellent transparencyColorless transparent plexiglass plate, light transmittance of more than 92%2. excellent weather resistanceAdaptability to the natural environment is very strong, even for a long time in sunlight, wind and rain will not change its performance, anti-aging properties, and can also feel comfortable in the outdoor use.3. good processabilityThe utility model is suitable for mechanical processing and easy thermal forming, and the acrylic plate can be dyed, and the surface can be painted, silk screen or vacuum coating.4. excellent comprehensive performanceAcrylic plate has many varieties, rich colors and excellent comprehensive properties. It provides diversified choices for the designers. The acrylic board can be dyed, and the surface can be painted, silk screen or vacuum coating.

- Q: What kind of raw material does glass form? What is the general smelting process?

- Before people made of glass which has a lot of people use a lot of bubbles, there is no way to take out that European countries made out of glass without bubbles, other countries about the scary, stirring

- Q: Use of glass flake cement

- Coatings containing glass flakes are much harder than epoxy or polyester resin without glass flakes, and therefore have higher surface abrasion resistance.

Send your message to us

Safety Clear Tempered Laminated Glass Factory Price For stairs/floor/balustrade Glass

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches