Clear Double Tempered Laminated Glass 3+0.38+3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Heat Absorbing Glass,Heat Reflective Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

colour: clear

edge: flat edge,grind edge,finepolished edge,bevelled edge

Packaging & Delivery of Double Tempered Laminated Glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: 7-15 days

Specifications of Double Tempered Laminated Glass

1 Safety

2 Strength for resistance to impact

3 Strength for resistance to human body5 Sound insulation

1) safety

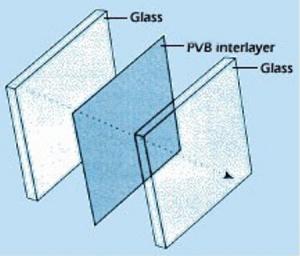

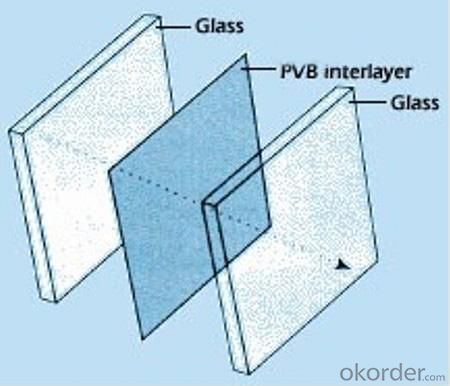

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living.

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

4)application

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating,aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.

Specification of Double Tempered Laminated Glass

The color of PVB

(1) Euro grey

(2)light brozen

(3)dark blue

(4)green

(5)ocean blue

(6)F-green

(7)blue-green

(8)milky white

(9) light yellow

(10)chinese red

(11)purplish red

(12)orange

(13)clear

the type of glass

(1)clear float glass

(2)tinted glass

(3) reflective glass

Size

3300*2250mm,3300*2134mm,3210*2250,2440*1830mm,2440*1530 etc

Thickness

6.38mm,6.76mm,8.38mm,8.76mm,10.38mm,10.76mm,12.38mm,16.76mm etc

Laminated Glass Performance Levels according to Thickness

Glass Characteristic |

Thickness (mm) |

UV Transmittance (%) |

LT (%) |

3+0.38+3mm Clear |

6.38mm |

5 |

89 |

6+0.38+6mm Clear |

12.38mm |

3 |

86 |

6+0.38+6mm Reflective |

12.38mm |

0.5 |

22 |

- Q: What role does zircon sand play in the production of glass? Is it a raw material for glass or a production process?

- Zircon is mainly an igneous rock formed from magma crystallized zirconium, silicon and oxygen composition of minerals. Zircon is also produced in the dikes and metamorphic rocks. It belongs to the tetragonal system, and is often a well developed cone shaped small tetragonal cylinder, but also irregularly granular. Crisp, broken shell like. It's high quality refractory. With Jin Hongshi, ilmenite, monazite and xenotime in beach sand, and the water, electricity, magnetic separation and other beneficiation process.

- Q: What is the raw material of glass made of?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history. The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass.

- Q: How is glass made? What are the main ingredients?

- Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) are crushed to damp the raw materials, and the iron bearing raw material is treated with iron to ensure the quality of the glass.

- Q: Long plastic soft glass is a food grade raw materials?

- The normal use of the family (including the dining table) is entirely without question

- Q: How can the vacuum tubes of solar water heaters be chromatic aberration? Is purple good or sky blue good?

- Appearance: A, nozzle, where the film is more than 800 degrees Celsius, sealing at high temperatures, part of the fall is inevitable. High temperature tube because of high temperature resistance, only about 1 cm long without film, while other tubes because of high temperature resistance, film shedding, length of about 2.5 cm. B, inner tube color: with naked eye observation, high temperature and high temperature pipe inner tube color is dark red (because the film bottom is copper), and the high efficiency tube and ordinary pipe is white (because the film bottom is aluminum). The third kind: Zijin tube, which is plated with copper, absorbs heat and is better than three executives. The color is purple, so it is called purple tube

- Q: What is a hollow glass?

- At present, the domestic glass mainly has three kinds: (a) aluminum type sealant; (two) aluminum type double sealing; (three) composite sealing strip type insulating glass. Aluminum type sealant, because of its poor sealing performance, easy to cause the glass into moisture, dew and frost, service life short, the hollow glass gradually eliminated. The raw materials of two kinds of hollow glass is mainly: glass, aluminum, gusseted, butyl rubber, two-component polysulfide rubber or silicone rubber, composite desiccant, underground sealant.

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- I do PVC mesh fabric, and it should be used on the hull of your yacht

- Q: Medium temperature glass flake clay products

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale, which is made of c- glass, has excellent chemical durability.

- Q: Which brand of thermos cup is safe, double glass is not really glass, there is no other add, affect health?

- Stainless steel material specifications, which 18/8 said that the stainless steel material composition containing 18% chromium, containing 8% nickel, reached the standard materials, in line with the national food standards is the green environmental protection product, rust and corrosion products. Ordinary stainless steel cup body color is pale and dark, if the brine into the concentration of 1% will produce rust after 24 hours, which contains some elements exceed the standard, the direct harm to human health.

- Q: What are the raw materials of water glass?

- The wet production of quartzite powder and caustic soda as raw materials in autoclave, 2 - 3 atmospheric pressure steam reaction, generating liquid water glass.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Clear Double Tempered Laminated Glass 3+0.38+3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords