Clear Double Tempered Laminated Glass 6+0.38+6mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Heat Absorbing Glass,Heat Reflective Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

colour: clear

edge: flat edge,grind edge,finepolished edge,bevelled edge

Packaging & Delivery of double tempered laminated glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: 7-15 days

Specifications of double tempered laminated glass

1 Safety

2 Strength for resistance to impact

3 Strength for resistance to human body5 Sound insulation

1) safety

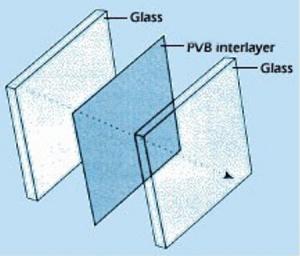

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living.

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

4)application

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating,aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.

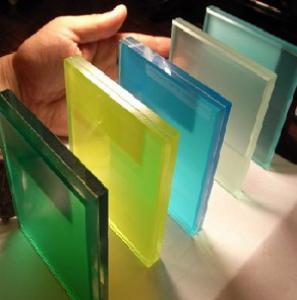

Specification of double tempered laminated glass

The color of PVB

(1) Euro grey

(2)light brozen

(3)dark blue

(4)green

(5)ocean blue

(6)F-green

(7)blue-green

(8)milky white

(9) light yellow

(10)chinese red

(11)purplish red

(12)orange

(13)clear

the type of glass

(1)clear float glass

(2)tinted glass

(3) reflective glass

Size

3300*2250mm,3300*2134mm,3210*2250,2440*1830mm,2440*1530 etc

Thickness

6.38mm,6.76mm,8.38mm,8.76mm,10.38mm,10.76mm,12.38mm,16.76mm etc

Laminated Glass Performance Levels according to Thickness

Glass Characteristic | Thickness (mm) | UV Transmittance (%) | LT (%) |

3+0.38+3mm Clear | 6.38mm | 5 | 89 |

6+0.38+6mm Clear | 12.38mm | 3 | 86 |

6+0.38+6mm Reflective | 12.38mm | 0.5 | 22 |

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Acid: hydrochloric acid, sulfuric acid alkali: calcium hydroxide salt: soda ash, limestone, other: silica, mercury, lead and other small amounts of metal

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- High quality glass steel products appearance has no obvious cracks, pores are less pure, bright color, good transparency, toughness has a certain strength, good surface smoothness, long service life; while the poor quality of the glass steel product surface crack, more pores, mixed color gloss is not enough. Its service life is also short.

- Q: What chemicals added to the PVB resin powder can be diluted into a transparent liquid?

- Polyvinyl butyral (Polyvinyl butyral) PVB.... PVB resin itself contains many hydroxyl (OH) radicals, with some thermosetting resin (Thermosetting resin) (Cross linking reaction produced a bridging reaction) to improve chemical resistance and film hardness and excellent coating properties. High transparency (Transparent), (elastic), elastic toughness (Toughness), alkali resistance, oil resistance and flexibility, impact resistance and low temperature. Because of its special chemical structure, so there is a strong combination of glass, metal, ceramic, plastic, leather and wood.

- Q: What is resin glass fiber reinforced plastic?

- Raw materials: glass fiber / or its products + resin + (filler) + other additives;Process: hand / pull / winding / molding / injection molding etc..Resin is only a raw material for the production of glass fiber reinforced plastic! That's not what you call it.

- Q: The main reasons for failure of air glass are outlined

- The requirements of the desiccant performance must have low initial adsorption capacity, easy production and operation, while the remaining strong adsorption capacity, ensure the sealing hollow glass has more adsorption capacity and only adsorption, water molecules with wear strength, usually choose 3A molecular sieve as a special adsorption of hollow glass as for the special agent, contain volatile sealant, special ability requirements of desiccant adsorption of organic molecules, the general choice of 13X molecular sieve, molecular adsorption as water and adsorption of organic compounds by sieve. The desiccant absorption capacity of the water vapor as the desiccant temperature varies, different desiccant absorbs water vapor in a given number of different temperature conditions, depending on the hollow glass cavity obtained rate of water vapor, water vapor growth rate is a function of several factors

- Q: How is glass made? What is its raw material?

- Glass is formed by the melting of sand with other chemicals. Glass raw materials for natural ore, the ore will be crushed first, processed into powder, according to the type of glass, according to the formula made of ingredients, into the glass furnace for melting, forming glass liquid. The glass passes through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q: What is the raw material of glass glue?

- Mainly divided into two categories: neutral acid silicone rubber polyurethane adhesive can be indoor and outdoor weathering 107 RTV silicone rubber and calcium carbonate, silica, additives, mixing, vacuum glass glue chemical formula: 107RTV+SiO2+CaCO3= glass glue according to the technical requirements of the chemical equipment selection will differ.

- Q: Why are most of the chemical instruments made from glass?

- Because experiments require high temperatures, heating, freezing, and many complex processes of chemical reactions,

- Q: Is glass fiber reinforced metal material?

- Glass steel (English: Glass Reinforced Plastic, GRP, or Fiber Reinforced Plastic, English: FRP) also known as glass steel or glass fiber reinforced plastic, is a kind of polymer with epoxy resin as matrix, glass steel or carbon fiber reinforced composite material by composite technology and made.

- Q: What materials do you need to make glass?

- The chemical composition of ordinary glass is Na2O, CaO, 6SiO2, the main component is silica, is a kind of amorphous structure with irregular structure. Widely used in buildings for wind and light transmission; of mixtures.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Clear Double Tempered Laminated Glass 6+0.38+6mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords