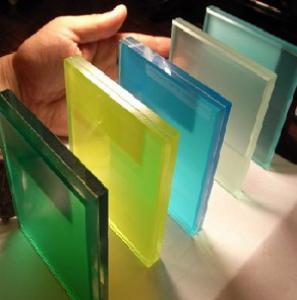

Tinted Laminated Glass 6.38mm-30mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters watt

- Supply Capability:

- 1500 Square Meter/Square Meters per Day watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Heat Absorbing Glass,Heat Reflective Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

colour: clear,royal blue,ford blue,ocean blue,F-green

edge: grounding edge

Interlayer: PVB

PVB thickness: 0.38mm0.76mm1.14mm1.52mm

Usage: building,windows,doors PVB color: clear ,yellow,red ,green,blue and so on

Max size: 3660*2440mm

Min size: 300*300mm

certificate: ISO CCC

raw material: float glass,tempered glass

Packaging & Delivery of Tinted Laminated Glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: within 15 days after receive deposit

Specifications of Tinted Laminated Glass

1.Yaojing laminated glass

2. Certificate CCC

3. Good quality and price

4.Fast Delivery time

laminated glass 6.38mm-30mm

The color of pvb

(1) Euro grey

(2)light brozen

(3)dark blue

(4)green

(5)ocean blue

(6)F-green

(7)blue-green

(8)milky white

(9) light yellow

(10)chinese red

(11)purplish red

(12)orange

(13)clear

the type of glass

(1)clear float glass

(2)tinted glass

(3) reflective glass

Size

3300*2250mm,3300*2134mm,3210*2250,2440*1830mm,2440*1530 etc

Thickness

6.38mm,6.76mm,8.38mm,8.76mm,10.38mm,10.76mm,12.38mm,16.76mm etc

Application of Tinted Laminated Glass

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating,aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.

Laminated Glass Performance Levels according to Thickness

Packing of Tinted Laminated Glass:

Seaworthy wooden crates

Iron belt for consolidation

Interlayer paper between two sheets

- Q: Is it a vacuum cup with fluorine coating that affects the health?

- Fluorine is a nonmetallic chemical element, chemical symbol F, atomic number 9. Fluorine is the halogen elements of a periodic system of A VII family, located in the second period in the periodic table of elements.

- Q: Polypropylene short fiber and glass fiber if different

- Polypropylene fiber is resistant to acid and alkali, and glass fiber has poor alkali resistance.

- Q: Tile selection, paving process

- The stone used for indoor ground is generally polished board, the thickness of the plate is about 20 millimeters, and now there are thin plates, the thickness is about 10 millimeters, suitable for family decoration. Each block is 300 mm x 300 mm, ~500 mm * 500 mm. Plates and 1:2 cement mortar can be used with 107 adhesive plaster.

- Q: Long plastic soft glass is a food grade raw materials?

- No, this is the PVC material processing process, there will be plasticizers, etc., although non-toxic, harmless, but the food grade standards or worse.

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- Ordinary glass plate glass, wire glass and quartz glass (also known as crystal glass) a molding. Wired glass as the quartz glass; only a raw material of sandstone or silica or quartz sand.Tempered glass is made of flat glass as raw material for re processing: the cut of the flat glass into the tempering furnace, heating to about 650 degrees, with cold air quenching, glass forming hardening - tempering. Accomplish!

- Q: What are the cutting and cutting of acrylic and aluminum-plastic plates?

- The splint knife acrylic, aluminum plate can also draw three splint that can also use a hacksaw, to fine tooth saw blade.

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- There are two kinds of molding process, high temperature molding (SMC molding) and room temperature molding (hand paste or vacuum assisted molding). SMC molded, there is no problem of glass fiber, hand paste or vacuum assisted molding. If it takes a long time, you will see the bare phenomenon of glass fiber. You can look at the back of his shell, and if you see the surface is not smooth, it should be hand shaped, usually if the car's output is very large, with SMC molding more. My humble opinion. I hope I can help you.

- Q: Samsung LCD panel information

- This screen is indeed the original Samsung screen, Samsung Electronics, Tianjin Corporation assembly production.TSEC is the sign of Tianjin's samsung. So he wrote the MADE IN CHINA (TSEC) behind him

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- Float glass: float glass surface flat, good brightness, no bubble and tumorLattice glass: the surface of the lattice is not very smooth, and the ripples can be seen from the side. Uneven thickness

- Q: What is the glass industry?

- To process liquid glass into desired shapes, such as flat plates, various vessels, etc.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Tinted Laminated Glass 6.38mm-30mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters watt

- Supply Capability:

- 1500 Square Meter/Square Meters per Day watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches