Glass Wool Batts, Glass Wool Blanket Suppliers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

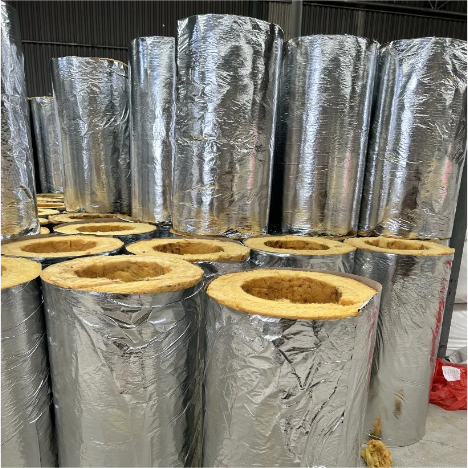

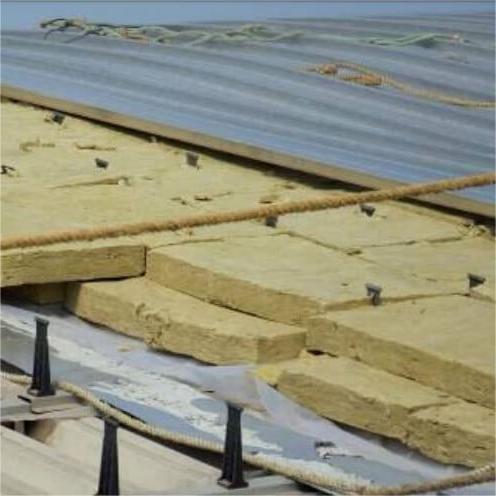

Glass wool, which is made from achromatism plate glass and quartz sand, is inorganic heat preservation material. It is a kind of green building material. What’s more, the scrap can be recycled and be reused. It can meet requirement of environmental protection. It belongs to upmost fire resistance grade, Class A. It totally meet fire proofing requirement of national standard. It can guarantee the safety of building.

Main features:

• Unique technology; rebound degree after compressive packing is up to 99.2%.

• Soft and long glass fibers can maximally lessen flying catkins in the construction.

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

• Grade A1 incombustible materials.

Applications:

Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

Installation:

FAQ:

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutelyput an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue has low air permeability, meaning it restricts the flow of air.

- Q: How is fiberglass mat tissue used in the production of windshields?

- The unique properties and functions of fiberglass mat tissue make it a crucial component in windshield production. To strengthen and increase the durability of the glass, manufacturers use fiberglass mat tissue as a reinforcement material. In the manufacturing process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering upon impact and holding it together for the safety of the vehicle occupants. By serving as a reinforcing material, fiberglass mat tissue improves the mechanical properties of the windshield. It enhances the impact resistance, reducing the likelihood of cracks or chips caused by stones, debris, or other objects. This reinforcement also provides structural integrity, allowing the windshield to withstand extreme weather conditions and vibrations without affecting its functionality. Moreover, fiberglass mat tissue aids in reducing noise transmission and vibrations. Its sound-damping properties contribute to a quieter and more comfortable driving experience by minimizing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue enables the production of curved windshields. The material's flexibility allows it to conform to different shapes and contours, enabling manufacturers to create windshields with customized designs and improved aerodynamics. In conclusion, fiberglass mat tissue plays a vital role in windshield production. Its reinforcement properties enhance the strength and impact resistance of the glass, ensuring the safety of vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: Is fiberglass mat tissue resistant to moisture?

- Yes, fiberglass mat tissue is resistant to moisture.

- Q: Does fiberglass mat tissue provide any moisture insulation?

- Yes, fiberglass mat tissue provides some level of moisture insulation. Fiberglass is known for its water-resistant properties, and the mat tissue made from fiberglass helps to further enhance this characteristic. It acts as a barrier against moisture, preventing it from seeping through and causing damage to underlying materials. However, it is important to note that fiberglass mat tissue is not completely waterproof and may allow some moisture to penetrate over time. Therefore, it is recommended to use additional moisture insulation materials in situations where complete waterproofing is required.

- Q: Can fiberglass mat tissue be used for repairing fiberglass kayaks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass kayaks. Fiberglass mat tissue is a lightweight material that is commonly used in the repair and reinforcement of fiberglass products, including kayaks. It is designed to be easily moldable and conform to the shape of the damaged area. By applying the fiberglass mat tissue with an epoxy resin, it can effectively reinforce and bond the damaged sections of a fiberglass kayak, restoring its strength and durability. It is important to ensure that the damaged area is properly prepared and the fiberglass mat tissue is applied correctly to achieve a strong and long-lasting repair.

- Q: Can fiberglass mat tissue be used for automotive repairs?

- Automotive repairs can indeed utilize fiberglass mat tissue. This versatile material finds its application across various industries, including the automotive sector. It serves to reinforce and mend auto body panels, while also addressing cracks, holes, and other damages that may afflict the vehicle's body. Comprised of resilient fibers held together by a resin, fiberglass mat tissue boasts exceptional strength and flexibility. As a result, it proves to be an ideal choice for automotive repairs. Its malleability allows it to conform to different contours and shapes of car parts, ensuring a seamless and precise restoration. Moreover, fiberglass mat tissue possesses the desirable qualities of being lightweight and durable, both of which are vital attributes for automotive repairs. It offers unparalleled resistance against corrosion, weathering, and other external elements, thereby guaranteeing the longevity of the repair. Additionally, it provides reliable impact resistance, effectively safeguarding the repaired area from further harm. Furthermore, fiberglass mat tissue harmonizes effortlessly with a wide range of automotive coatings, including primers, paints, and clear coats. This compatibility ensures a flawlessly smooth and professional finish once the repair work is completed. To summarize, fiberglass mat tissue stands as an appropriate choice for automotive repairs due to its formidable strength, flexibility, durability, and compatibility with automotive coatings. It is commonly employed in the industry to reinforce and mend auto body panels, address damages, and achieve an impeccable finish.

- Q: How does fiberglass mat tissue perform in terms of mold and mildew resistance?

- Fiberglass mat tissue generally performs well in terms of mold and mildew resistance. The material's non-porous nature and moisture resistance help inhibit the growth of mold and mildew. Additionally, fiberglass mat tissue is often treated with anti-fungal agents during the manufacturing process, further enhancing its resistance to mold and mildew. However, it is important to note that proper installation and maintenance are crucial to ensure optimal mold and mildew resistance.

- Q: Does fiberglass mat tissue provide good thermal conductivity?

- No, fiberglass mat tissue does not provide good thermal conductivity.

- Q: Is fiberglass mat tissue recyclable?

- Yes, fiberglass mat tissue is recyclable.

- Q: What is the lifespan of fiberglass mat tissue?

- The lifespan of fiberglass mat tissue can vary depending on factors such as the quality of the material, environmental conditions, and proper maintenance. However, on average, fiberglass mat tissue can last anywhere from 20 to 30 years.

Send your message to us

Glass Wool Batts, Glass Wool Blanket Suppliers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords