Glass Wool Insulation Blanket - Glass Wool Suppliers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Insulation Glass Wool Blanket Suppliers

1.Structure of Glass Wool Insulation Glass Wool Blanket Suppliers:

Glass wool with Facing is an industrial product made by spinning glass into a fibrous material that can be packed in mats and Blankets. This product is used as insulation and in other applications, like for air filters. Glass wool is 100% recyclable. It is manufactured from sand and recycled glass(up tp 80% cullet) and offers a very positive environmental balance sheet. It protects the environment, from the beginning to the end of its life cycle and gives more comfort and savings to the occupants of the buildings it insulates.

Glass wool raw materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

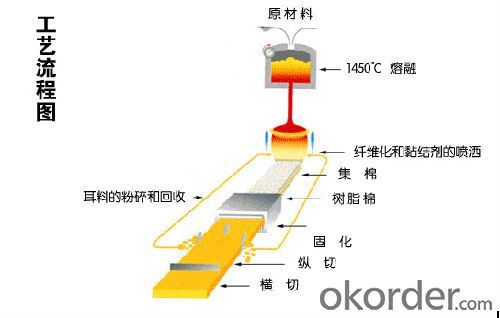

The Manufacturing Process

Melting / Forming into fibers /Continuous-filament process/Staple-fiber process/ Chopped fiber/ Glass wool / Protective coatings /Forming into shapes

2.Main Features of Glass Wool Insulation Glass Wool Blanket Suppliers:

The glass wool Blanket with Facing is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including Blankets, Blankets and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

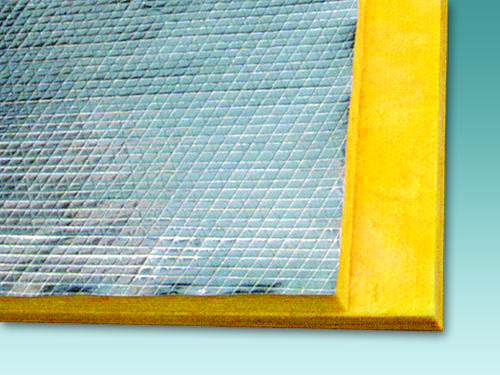

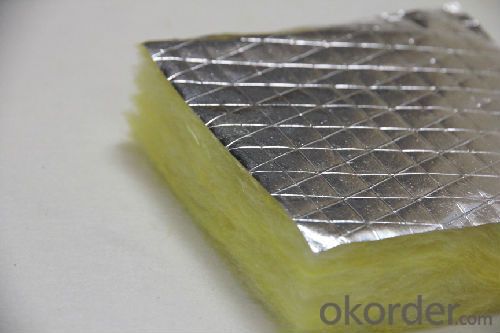

3. Glass Wool Insulation Glass Wool Blanket Suppliers Images

4. Glass Wool Insulation Glass Wool Blanket Suppliers Specification

The glass wool Blanket is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The glass wool Blanket with Facing surface has good capability of heat radiation protection.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 12-96 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 1200-3000 |

Both unfaced and faced felts can be provided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

- Q: Could centrifugal glass wool be treated as cold insulation material?

- yes, central air conditioning is useful.

- Q: What does the thermal insulation test of glass rock wool include?

- Appearance, dimensional deviation(length, width, height), shot content, average diameter of fibers, flatness deviation, right-angle deviation, water absorption coefficient, hydrophobic rate, short-term water absorption, tensile strength perpendicular to the surface, compression strength, heat conductivity coefficient, dimensional stability, noise reduction coefficient, acidity coefficient, vapor diffusion resistance factor, long-term water absorption, combustion performance. These are testing programs of rock wool thermal insulation boards. The raw materials and performance of which are different from that of glass wool. In addition to the different areas, the required testing programs are different too. My answer is for reference only.

- Q: Are there any differences between glass wool and rock wool in terms of appearance, I can't distinguish them, why?

- They are completely different products, and put it in a simple way, glass wool is made of glass, rock wool is made of stone,

- Q: Which is more effective in retarding fire, rock wool or glass?wool? What is the difference between rock wool and glass wool?

- In terms of fireproof effect, rock wool is certainly better than glass wool. The maximum temperature of rockwool is 1100 ℃, and glass wool is only 600 ℃. In addition if used in the external walls, the highest unit weight of glass wool can only be in the range of 60-90, but rock wool can be over 140. Generally glass wool can not be used in external wall at present. Only rock wool is A grade fireproof material.The heat conductivity coefficient of glass wool is lower than glass wool and the fibre length of rock wool is longer than glass wool. As for price, tons of glass wool rock is more expensive than that of rock wool. However, if counted by square size, glass wool is cheaper per square size than rock wool.

- Q: Polyester and glass wool, which is better, and why?

- The first one is better, it has good flexibility.

- Q: How to use glass wool for filtering?

- It depends on the filtering materials, if the solid particles are large, you can directly use ordinary funnel but not filter paper, if solid particles are small, you can use filter paper, you can try to use a small amount of filtering materials, and decide in accordance to the filtrate state, the trial is necessary and you will know after lots of trials.

- Q: What's the types of glass wool points? do they have the same sound insulation effect?

- Rock wool and glass wool have poor sound insulation effect, and different prices, glass wool is easy for construction.

- Q: does the glass wool can be used as building materials?

- Currently, it is still good.

- Q: What is the difference between glass wool and rock wool?

- Production of raw materials and different processes

- Q: How about the thermal insulation performance of glass wool?

- The features of glass wool mainly include light weight, easy installation, high thermal insulation efficiency, low hygroscopicity, and strong vibration resistance. Fibers of raw materials of glass wool are relatively even in terms of length and thickness, they are closely intertwined during processing procedures. The interwoven structure and its heat conduction are at a right angle, which can effectively retain heat. It operates simply during installation and use, simple common tools are needed to cut. Meanwhile, there will not be disjointed or stretched in use. There are a lot of tiny air voids in the glass wool, thus the physical property is also relatively stable. It is commonly used in various heating, ventilation, tank, air-conditioning adjustment, the performance of which is significant. Of course, the glass wool can also be customized, we can make glass wool with special specification according to your requirements. Using glass wool as thermal insulation materials has been a very long time, and we found that in a quite a long comparison test, the thermal insulation performance is fairly stable, which will not lead to accidents in use.

Send your message to us

Glass Wool Insulation Blanket - Glass Wool Suppliers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords