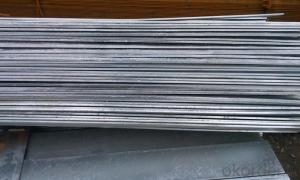

Supply Steel Flat; Flat Steel Bars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Spring Steel can be divided into two types. One is carbon spring steel, and other one is alloy spring steel.

Alloy spring steel is based on carbon spring steel, by adding one or more alloying elements to improve the mechanical properties, hardenability and other properties to meet the requirement for manufacturing all kinds of spring steel.

Specification of Spring Steel:

-Material: 70Si2CrA

-Production: Hot rolled or cold rolled

-Standard: GB/T·5218-1999

-Type: Spring Steel

-Alloy or no: Alloy

Mechanical Properties:

-Annealing Condition:

1, Tensile Strength: σb/MPa:≤835

2, Elongation: δ/%:≥8

-Quencher condition:

1, Tensile strength: σb/MPa:785~1175

2, Elongation: -

Usage/Applications of Spring Steel:

For manufacturing all kinds of flat spring or round spring with small sections, clockwork spring,

Packaging & Delivery of Spring Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the common forming techniques used for steel flat bars?

- Steel flat bars can be formed using various techniques such as hot rolling, cold rolling, and extrusion. In hot rolling, the steel is heated above its recrystallization temperature and then passed through rollers. This reduces the thickness of the steel and shapes it into a flat bar. This method is popular for creating steel flat bars with precise dimensions and a smooth surface finish. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature. This process is used to further refine the thickness and surface finish of the steel flat bar formed through hot rolling. Additionally, cold rolling can enhance the strength and hardness of the steel. Extrusion is another technique that is employed to form steel flat bars. It involves forcing the steel through a die, resulting in the desired shape of a flat bar. Extrusion is commonly utilized when intricate cross-sectional profiles are required or when high precision is vital for the final product. Additional forming techniques for steel flat bars include bending, shearing, and welding. Bending is useful for achieving specific shapes or angles in the flat bar, while shearing is employed to cut the flat bar to the desired length. Welding, on the other hand, is a joining process used to connect multiple steel flat bars together or to other steel components.

- Q: Can steel flat bars be used for manufacturing storage racks?

- Indeed, one can utilize steel flat bars in the production of storage racks. Renowned for their robustness and longevity, steel flat bars prove to be an exceptional selection when constructing storage racks that must bear substantial burdens. Furthermore, the bars' flat structure ensures a steady surface for the storage of diverse items. Moreover, steel flat bars can be effortlessly joined through welding or bolting, thus facilitating the creation of the desired rack configuration and guaranteeing adaptability and customization to cater to distinct storage requirements.

- Q: What is the typical shear strength of steel flat bars?

- Depending on the specific grade and thickness of the material, the shear strength of steel flat bars can vary. Typically, steel flat bars exhibit shear strengths ranging from 40,000 to 60,000 pounds per square inch (psi). It is crucial to consider that these values may differ due to factors like heat treatment, composition, and manufacturing processes employed in the production of the steel flat bar.

- Q: Can steel flat bars be used for making jewelry?

- Yes, steel flat bars can be used for making jewelry. Steel is a versatile and durable material that can be crafted into various forms, including flat bars, which can then be shaped and manipulated into unique jewelry pieces. Steel jewelry has gained popularity in recent years due to its contemporary and industrial aesthetic. It offers a sleek and modern look that can be further enhanced by various finishes, such as polished, brushed, or even plated in gold or silver. Steel jewelry is also resistant to tarnish and corrosion, making it a practical choice for everyday wear. Additionally, steel flat bars can be easily engraved or stamped with designs, names, or meaningful symbols, adding a personal touch to the jewelry. However, it is important to note that steel is a heavy material, so it may not be suitable for delicate or lightweight jewelry designs.

- Q: How do steel flat bars differ from steel round bars?

- Steel flat bars and steel round bars exhibit dissimilarities in their shape and structural characteristics. The primary dissimilarity between steel flat bars and steel round bars lies in their shape. Steel flat bars possess a rectangular form with sharp edges and a level surface on the top and bottom. Conversely, steel round bars possess a circular cross-section, resembling a rod or cylinder. Regarding structural properties, steel flat bars and steel round bars also differ. Steel flat bars are often favored for applications necessitating a robust load-bearing capacity in a horizontal direction, such as weight support or structural stability provision. The flat surface facilitates better weight distribution, thereby preventing bending or warping under substantial loads. Contrarily, steel round bars are typically employed in applications requiring strength and durability in diverse directions, encompassing both vertical and horizontal forces. The circular shape of round bars confers excellent resistance to bending and twisting, rendering them suitable for usage in construction, machinery, and automotive components. Moreover, the manufacturing process for steel flat bars and steel round bars may diverge as well. Steel flat bars are usually fabricated through hot rolling, entailing the passage of heated steel through a succession of rollers to achieve the desired shape. Steel round bars can be manufactured via both hot rolling and cold drawing processes, where the steel is either heated and passed through rollers or drawn through a die to form the circular shape. In essence, steel flat bars and steel round bars can be distinguished based on their shape, structural properties, and manufacturing processes. Gaining an understanding of these disparities is vital when selecting the appropriate steel bar for a particular application.

- Q: Connect the equipotential terminal box to the ground flat iron. Can I use plain flat steel?

- Specification requirement is 25*4 or 40*4 hot galvanized flat steel, said the family specification is also very reasonable, even galvanized flat steel, long time buried in the soil or on the floor, the wall will be laying, easy to rust, if we use the normal flat iron, not to mention that, certainly rust, but the speed is much faster than galvanized flat steel!

- Q: What is the difference between flat steel and steel strip?

- Steel strips generally refer to sheet metal, and flat steel generally refers to medium and heavy plateFlat steel hot rail and cold drawn

- Q: Can steel flat bars be hardened or heat treated?

- Yes, steel flat bars can be hardened or heat treated, depending on the specific type of steel used. Heat treatment involves heating the steel to a specific temperature and then cooling it rapidly to achieve the desired level of hardness. This process can be used to increase the strength and durability of the steel flat bars. Hardening and heat treatment are commonly employed in various industries, such as construction, manufacturing, and automotive, to enhance the properties of steel flat bars and make them suitable for specific applications.

- Q: Lightning protection grounding, what is called three surface welding?

- The grounding position of the grounding body shall not be less than 3m; when the ground is embedded in the garbage or ash, it should be changed and compacted.The grounding body (line) shall be connected by welding, the welding seam should be full and adequate mechanical strength, no slag, undercut, crack, weld, welding defects such as pores, knocking the net after a drug paper, brush asphalt anticorrosive processing.

- Q: Can steel flat bars be used for making marine equipment or structures?

- Yes, steel flat bars can be used for making marine equipment or structures. Steel is a commonly used material in the marine industry due to its strength, durability, and corrosion resistance. Flat bars can be used for various applications such as constructing ship hulls, offshore platforms, or marine equipment like mooring bollards or boat ramps. However, it is important to choose the appropriate grade of steel that meets the specific requirements and standards for marine applications to ensure longevity and safety in harsh marine environments.

Send your message to us

Supply Steel Flat; Flat Steel Bars with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords