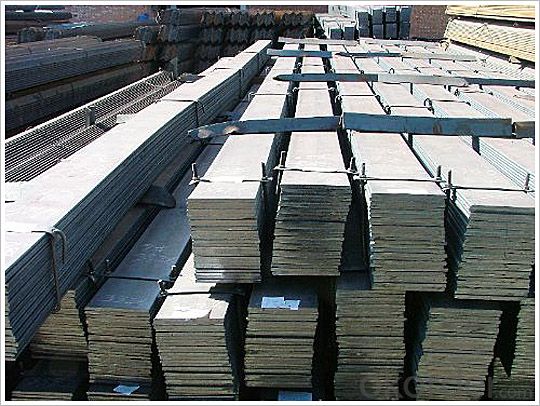

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Production Manufacturer | DAQIANG |

Product Name | Spring Steel Flat Bar |

Steel Type | Spring Steel |

Material | 5160 |

Others Available Material | 60Si2Mn, 5160H, SUP9, SUP9A, 55Cr3 etc. |

Thickness Range (mm) | 6-50 |

Width Range (mm) | 40-135 |

Usual length (mm) | 5800 |

Daily Capacity (Metric Ton) | 1000 |

Certificate | ISO9001: 2008 |

Edge | Round Edge / Right Angle |

Surface | None / Oil Protection |

Usage | Leaf Springs, Cultivator Blades, Garden Tools, Knifes etc. |

Samples | Free of Charge |

Chemical Composition (Common Material) | |||||||

C | Si | Mn | P | S | Cr | Cu | |

60Si2Mn | 0.56-0.64 | 1.5-2.0 | 0.7-1.0 | ≤0.035 | ≤0.035 | ≤0.35 | |

5160 | 0.56-0.64 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.04 | 0.7-0.9 | |

5160H | 0.55-0.65 | 0.15-0.35 | 0.65-1.1 | 0.6-1.0 | |||

SUP9 | 0.52-0.6 | 0.15-0.35 | 0.65-0.95 | ≤0.03 | ≤0.03 | 0.65-0.95 | ≤0.3 |

SUP9A | 0.56-0.64 | 0.15-0.35 | 0.7-1.0 | ≤0.03 | ≤0.03 | 0.7-1.0 | ≤0.3 |

55Cr3 | 0.52-0.59 | ≤0.4 | 0.7-1.0 | ≤0.025 | ≤0.025 | 0.7-1.0 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can steel flat bars be used for making machinery parts or components?

- Indeed, machinery parts or components can be made using steel flat bars. Steel, a versatile and durable material widely utilized in the manufacturing industry, is commonly employed for machinery and equipment. The malleability of steel flat bars allows for easy shaping, cutting, and welding, enabling the creation of various machinery parts and components including brackets, frames, supports, and gears. The superior strength and rigidity of steel make it an excellent choice for machinery applications, capable of withstanding heavy loads, providing stability, and resisting wear and tear. Moreover, steel can be machined and treated to enhance its properties, for instance, through heat treatment or surface coatings, further augmenting its suitability for machinery parts and components.

- Q: What are the different methods of surface coloring for steel flat bars?

- There are several different methods of surface coloring for steel flat bars, each with its own unique advantages and applications. Some of the most commonly used methods include: 1. Hot-dip galvanizing: This process involves immersing the steel flat bar into a bath of molten zinc, which creates a protective layer on the surface. Galvanizing provides excellent corrosion resistance and is often used in outdoor or high-moisture environments. 2. Powder coating: Powder coating involves applying a dry powder paint to the surface of the steel flat bar, which is then cured using heat. This method offers a wide range of color options, excellent durability, and resistance to chipping, scratching, and fading. 3. Electroplating: Electroplating is a process where a thin layer of metal, such as chrome or nickel, is deposited onto the steel flat bar's surface using an electric current. This method can enhance the appearance of the steel while also providing corrosion resistance. 4. Paint coating: The traditional method of applying paint directly to the surface of the steel flat bar is still widely used. It allows for a wide variety of colors and finishes, but the durability and corrosion resistance may not be as high as other methods. 5. Chemical coloring: This method involves using chemicals to create a controlled oxidation process on the steel flat bar's surface, resulting in various colors and shades. Chemical coloring can provide an attractive appearance while also increasing corrosion resistance. 6. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to steel flat bars. It involves creating an oxide layer on the surface through an electrochemical process, resulting in enhanced corrosion resistance and the ability to add color through dyes. Each of these methods has its own set of advantages and considerations, such as cost, environmental impact, durability, and aesthetic appeal. The choice of surface coloring method will depend on the specific requirements of the application, including the desired appearance, level of corrosion resistance, and budget constraints.

- Q: Can steel flat bars be used in fire-resistant structures?

- Fire-resistant structures can indeed utilize steel flat bars. Steel possesses natural fire-resistant properties as a result of its high melting point and low thermal conductivity. Moreover, construction frequently employs steel flat bars due to their robustness, longevity, and adaptability. These bars can be integrated into fire-resistant structures like walls, doors, and frames. Additionally, in fire-resistant buildings, steel flat bars function as structural supports and reinforcements. Nonetheless, it is crucial to emphasize that designing and constructing fire-resistant structures necessitates meticulous attention, encompassing the application of suitable fire-resistant coatings or insulation materials to heighten the overall fire resistance of the edifice.

- Q: Are steel flat bars commonly used in the transportation industry?

- Yes, steel flat bars are commonly used in the transportation industry. They are often used for constructing various components such as brackets, frames, and supports in vehicles like cars, trucks, and trailers. Steel flat bars are valued for their strength, durability, and versatility, making them a popular choice in transportation applications.

- Q: Are steel flat bars available in different lengths and widths?

- Indeed, an assortment of lengths and widths can be found for steel flat bars. The specific product and manufacturer play a significant role in determining the available options for length and width. Typically, steel flat bars can be obtained in lengths spanning from 6 feet to 20 feet, while widths can extend from 1/2 inch to 12 inches or even more. This broad range of variations in length and width offers enhanced flexibility in selecting the appropriate size of steel flat bars to cater to the specific requirements of any given project or application.

- Q: How do you cut a steel flat bar?

- In order to cut a steel flat bar, several tools are necessary. These include a metal cutting saw, a clamp or vice to secure the bar, and safety equipment like gloves and goggles. Here is a detailed step-by-step guide on how to cut a steel flat bar: Firstly, use a measuring tape and a marker to measure and mark the desired length of the steel flat bar. Ensure that the marks are clearly visible. Next, securely fasten the steel flat bar in a clamp or vice, making sure that it is tightly held and will not move while cutting. This will provide stability and prevent any accidental movements. For your safety, put on safety gloves and goggles to protect yourself from any flying metal fragments or sparks. Position the metal cutting saw perpendicular to the steel flat bar, aligning it with the marked cutting line. Start the saw and gradually guide the blade into the steel flat bar, applying steady and even pressure. Allow the saw to do the cutting work; avoid forcing or pushing too hard, as this could damage the saw blade or cause the steel to overheat. Continue cutting until you reach the marked cutting line. Take breaks periodically to allow the steel to cool down if necessary, as excessive heat may affect the cutting process. Once the cut is completed, turn off the saw and inspect the steel flat bar for any rough edges or burrs. Smooth out any imperfections using a metal file or sandpaper. Finally, remove the steel flat bar from the clamp or vice and clean up the work area, ensuring that all metal shavings are disposed of properly. Keep in mind that when cutting steel, it is important to exercise caution and follow proper safety protocols, as it can be sharp and produce sparks. If you are uncertain or lack experience, it is advisable to seek assistance from a professional or consult a metalworking specialist.

- Q: How do steel flat bars contribute to the overall aesthetics of architectural designs?

- Steel flat bars can contribute to the overall aesthetics of architectural designs by adding sleekness, modernity, and a sense of strength. Their clean lines and smooth surfaces create a visually appealing contrast against other architectural elements. Steel flat bars can be used to create eye-catching features like handrails, window frames, or decorative accents, enhancing the overall aesthetic appeal of the building. Additionally, their versatility allows architects to incorporate them into various design styles, from contemporary to industrial, making them a popular choice in architectural projects.

- Q: Can steel flat bars be used in the manufacturing of tools?

- Steel flat bars are capable of being utilized in the production of tools. Due to its robustness, durability, and adaptability, steel is extensively employed in the manufacturing of tools. By way of machining, shaping, and heat treatment, steel flat bars can be effortlessly transformed into a diverse range of tools, including wrenches, chisels, scrapers, and cutting tools. These flat bars can be cut, drilled, and welded to assume the desired form of the tool. Their inherent strength enables them to endure the forces and pressures encountered during tool usage. Additionally, steel flat bars exhibit excellent resistance to wear, ensuring that the tools remain fully functional even after repeated use. All in all, steel flat bars are a dependable and widely employed material for tool manufacturing.

- Q: Can steel flat bars be used for making hinges or latches?

- Indeed, hinges or latches can be crafted using steel flat bars. The utilization of steel flat bars is widespread in diverse contexts owing to their robustness, endurance, and adaptability. In the realm of hinges or latches, they furnish a dependable and robust mechanism for the act of opening and closing doors, cabinets, or other objects. The flat structure of these bars facilitates effortless installation and secure fastening to the respective surfaces. Moreover, steel boasts remarkable resistance to corrosion, rendering it suitable for employment both indoors and outdoors. In summary, the utilization of steel flat bars for fabricating hinges or latches is an exceptional choice, as it imparts stability and durability to the final product.

- Q: Are steel flat bars commonly used in the telecommunications industry?

- Steel flat bars are not commonly utilized in the telecommunications industry; instead, the industry predominantly depends on a range of electronic components, optical fibers, and cables to transmit and receive signals. Steel flat bars are more commonly employed in the construction, manufacturing, and engineering sectors to provide structural support and reinforcement. Nevertheless, there may be rare occurrences where steel flat bars find application within the telecommunications industry, such as in the construction of equipment racks or supports.

Send your message to us

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords