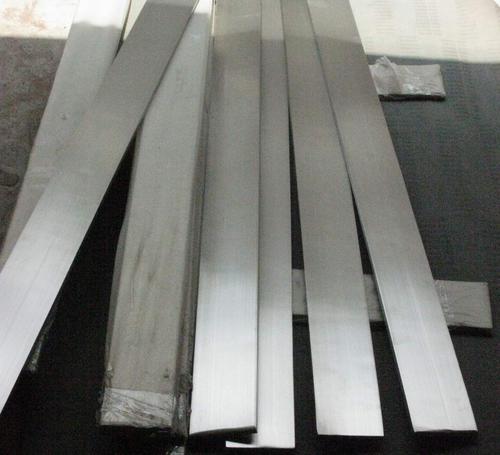

Grade Q235 Flat Bar Low Carbon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Grade Q235 Flat Bar Low Carbon at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Grade Q235 Flat Bar Low Carbon are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Grade Q235 Flat Bar Low Carbon are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How many tons of steel products could be loaded in containers?

A2: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: Can steel flat bars be used for making cutting tools?

- Yes, steel flat bars can be used for making cutting tools. Steel is a common material choice for cutting tools as it offers high strength, durability, and sharpness. Steel flat bars can be shaped, sharpened, and hardened to create a variety of cutting tools such as knives, chisels, or shears.

- Q: How do steel flat bars perform under cyclic loading conditions?

- Steel flat bars are known for their excellent performance under cyclic loading conditions. Due to their inherent strength and durability, steel flat bars can withstand repeated loading and unloading cycles without significant deformation or failure. The high tensile strength and elasticity of steel allow it to absorb and distribute the applied load evenly, preventing localized stress concentrations that could lead to fatigue or fracture. When subjected to cyclic loading, steel flat bars exhibit a phenomenon known as the S-N curve, which describes the relationship between stress amplitude and the number of cycles to failure. Initially, the steel flat bar can withstand a large number of cycles at low stress amplitudes without any noticeable damage. However, as the stress amplitude increases, the number of cycles to failure decreases. Nevertheless, steel flat bars have a long fatigue life and can endure a considerable number of cycles before failure. This is due to their ability to self-heal and resist crack propagation. Even if small cracks form during cyclic loading, the high yield strength and toughness of steel enable it to resist further crack growth, preventing catastrophic failure. Furthermore, the surface finish of steel flat bars plays a crucial role in their performance under cyclic loading conditions. A smooth surface finish helps to reduce the initiation and propagation of cracks, thereby enhancing their fatigue resistance. In summary, steel flat bars excel in handling cyclic loading conditions. Their high strength, elasticity, and ability to self-heal and resist crack propagation make them a reliable choice for applications subjected to repeated loading and unloading. However, it is crucial to consider the stress amplitude and surface finish to ensure optimal performance and longevity of steel flat bars under cyclic loading conditions.

- Q: Are steel flat bars suitable for load-bearing shelves or brackets?

- Load-bearing shelves or brackets can be supported by steel flat bars, as they are known for their strength and durability. Steel is an excellent choice due to its ability to withstand heavy loads. The flat shape of these bars provides stability and makes installation easy. Moreover, steel flat bars are resistant to bending and warping, ensuring the shelves or brackets remain sturdy and secure. Furthermore, steel can endure various environmental conditions, making it suitable for both indoor and outdoor use. Consequently, steel flat bars are a dependable and pragmatic option for load-bearing shelves or brackets.

- Q: What are the cost implications of using steel flat bars compared to other materials?

- The cost implications of using steel flat bars compared to other materials can vary depending on several factors. First and foremost, the cost of steel flat bars themselves needs to be considered. Steel is a widely available and commonly used material, which often makes it more cost-effective compared to other materials such as aluminum or titanium. Additionally, steel flat bars can be produced in large quantities, leading to economies of scale and lower production costs. Furthermore, steel is known for its durability and strength, making it a popular choice in construction and manufacturing industries. Its high tensile strength allows for the use of thinner and lighter flat bars, which can reduce material costs. Steel is also highly resistant to corrosion, which can extend the lifespan of the product, reducing maintenance and replacement costs in the long run. However, it is important to consider additional costs associated with steel flat bars. For example, steel is a denser material compared to alternatives like aluminum, which can increase transportation and handling costs due to its weight. Additionally, steel requires surface treatments or coatings to protect against rust, which may add an extra cost. In contrast, other materials like aluminum or titanium can have higher initial costs due to their scarcity or more complex manufacturing processes. However, these materials may offer benefits such as lighter weight, corrosion resistance, or specific mechanical properties that can justify their higher cost in certain applications. In summary, the cost implications of using steel flat bars compared to other materials depend on factors such as the initial material cost, durability, maintenance, transportation, and specific requirements of the project. It is essential to carefully evaluate the specific needs and priorities of the application to determine the most cost-effective option.

- Q: Can steel flat bars be used for shelving systems?

- Yes, steel flat bars can definitely be used for shelving systems. Steel flat bars are known for their durability and strength, making them an ideal choice for constructing sturdy shelving units. They can support heavy loads without bending or warping, making them suitable for storing a variety of items. Additionally, steel flat bars can be easily customized and cut to the desired length, allowing for flexibility in shelving design. Overall, steel flat bars offer a reliable and long-lasting solution for shelving systems in both residential and commercial settings.

- Q: How many steel tubes can be used instead of 60 * 10 flat steel?

- It can also be hardened by machine speed. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel.

- Q: Can steel flat bars be used for manufacturing storage racks or shelves?

- Steel flat bars are suitable for the manufacturing of storage racks or shelves. They are extensively utilized in the construction sector owing to their robustness and resilience. These bars offer a solid foundation for storage racks or shelves and can withstand heavy loads without any deformation or distortion. Furthermore, it is effortless to weld or bolt steel flat bars together, enabling the creation of customized storage solutions tailored to specific needs. Consequently, opting for steel flat bars is an outstanding decision when it comes to manufacturing storage racks or shelves.

- Q: What industries commonly use steel flat bars?

- Steel flat bars find widespread use across a diverse range of industries owing to their versatility and durability. Construction, manufacturing, automotive, infrastructure, and engineering are some of the sectors that frequently employ steel flat bars. Within the construction industry, steel flat bars serve multiple purposes, functioning as support beams, frames, braces, and structural components in buildings and bridges. By offering strength and stability, they prove ideal for withstanding heavy loads and pressure. In manufacturing, steel flat bars play a crucial role in the fabrication of machinery, equipment, and tools. Their malleability allows for easy shaping and machining, enabling them to meet specific requirements and suit various manufacturing processes. The automotive industry relies on steel flat bars extensively, particularly in the production of vehicle chassis and body frames. These bars provide the necessary strength and rigidity to endure the stresses and strains endured by automobiles, ensuring safety and durability. Infrastructure projects such as highways, railways, and airports make extensive use of steel flat bars as well. They are employed in the construction of beams, columns, and other structural elements, furnishing the requisite strength to bear heavy loads and withstand environmental conditions. Engineering industries heavily depend on steel flat bars for a wide array of applications. These bars are commonly utilized in the fabrication of machinery, equipment, and components that necessitate strength, resilience, and versatility. Furthermore, they are used in constructing support structures, frames, and braces required for various engineering projects. In conclusion, steel flat bars are widely utilized in the construction, manufacturing, automotive, infrastructure, and engineering sectors. Their versatility, strength, and durability render them indispensable for numerous applications and projects within these industries.

- Q: Can steel flat bars be used in the manufacturing of conveyor systems?

- Yes, steel flat bars can be used in the manufacturing of conveyor systems. Steel flat bars are commonly utilized for their strength, durability, and versatility, making them suitable for various industrial applications, including conveyor systems. They can be used for constructing frames, supports, guides, or even as conveyor belts in certain cases. Steel flat bars provide stability and can withstand heavy loads, making them an ideal choice for conveyor system manufacturing.

- Q: Can steel flat bars be welded or joined together?

- Yes, steel flat bars can be welded or joined together. Welding is a common method used to join metal components, including steel flat bars. Welding involves melting the edges of the steel bars and fusing them together using a welding filler material. This creates a strong and durable bond between the flat bars. However, it is important to ensure that the steel flat bars being welded are of the same or similar composition to prevent any issues with the weld quality. Additionally, proper welding techniques and equipment should be employed to achieve a high-quality weld and ensure the structural integrity of the joined steel flat bars.

Send your message to us

Grade Q235 Flat Bar Low Carbon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords