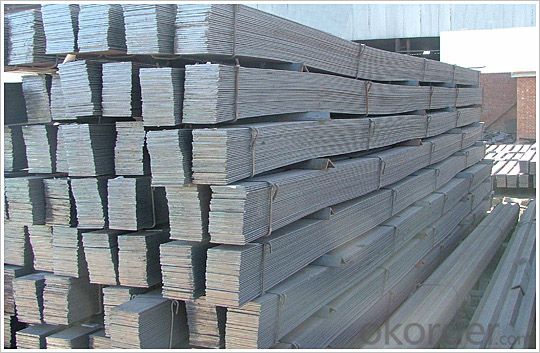

Flat Steel high quality slitting hot rolled q235 black carbon steel flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | at mill's standard packing in bundles / as per customer's packing instruction |

| Delivery Detail: | 5 ~ 20 days after receiving the deposit |

Specifications

flat bar

1.all the specifications

2.large quantity

3.best service

4.strict quality control

Type | Flat bar |

Grade: | A36, S235jr, St37-2, SS400, Q235,Q195 |

Standard: | AISI, ASTM, BS, JIS, GB |

Color | Black or galvanized |

Size | 10*1.5-870*12mm |

Payment terms | L/C,T/T, etc. |

Price term | Exw,FOB/CIF/CNF or as required |

Application | Construction; ship building; communication tower,steel grating etc... |

Market | Application for Australia, Southeast Asia,India, Mid-East and African market. |

Packaging Details: | At mill’s standard packing in bundles / as per customer's packing instruction |

- Q: How do you store and transport steel flat bars safely?

- To ensure the safe storage and transportation of steel flat bars, it is essential to follow several important steps: 1. Stack the bars correctly: Proper stacking is crucial in preventing damage. Align each layer of bars horizontally and evenly, distributing the weight evenly across the stack to maintain its structural integrity. 2. Provide adequate support: Prevent sagging or bending of the bars by using sturdy supports such as appropriately sized pallets or racks. Ensure that the supports can handle the weight and size of the bars. 3. Secure the stack: To avoid shifting during transportation, securely fasten the stack with straps or bands. Make sure they are tightly fastened, ensuring that the bars remain in place throughout transit. 4. Take protective measures: Steel flat bars are vulnerable to corrosion, especially when exposed to moisture. Protect them from environmental elements during storage and transportation by using protective covers or wrapping the bars in moisture-resistant materials to prevent rust or damage. 5. Use proper lifting and handling techniques: When moving the bars, employ suitable lifting equipment like forklifts or cranes to prevent accidents or injuries. Ensure that the equipment is capable of handling the weight of the bars and that operators are trained in safe lifting practices. 6. Considerations for long-distance transportation: If transporting the bars over long distances, it may be necessary to utilize specialized shipping containers or trucks equipped to handle heavy loads and provide adequate protection from external elements. By adhering to these guidelines, you can minimize the risk of damage, accidents, and corrosion, ensuring the safe delivery of steel flat bars to their intended destination.

- Q: What are the different methods of surface texturing for steel flat bars?

- Steel flat bars can be textured using various methods, each with its own benefits and applications. These methods allow for the creation of different textures and patterns on the bars, enhancing their appearance, grip, or functionality. Common techniques for surface texturing of steel flat bars include: 1. Shot blasting: By propelling small metal or abrasive particles onto the bars at high speeds, this method removes scale, mill scale, or rust, resulting in a clean and rough finish. 2. Sanding or grinding: Using abrasive tools like sandpaper or grinding wheels, material is manually removed from the bars' surface, creating textured finishes with patterns or grooves. 3. Knurling: This process involves rolling or pressing ridges or grooves onto the bars' surface, improving grip and preventing slipping, making it suitable for non-slip applications. 4. Acid etching: Chemical solutions selectively remove a thin layer of the steel's surface, creating precise and intricate textured patterns, including designs or logos. 5. Roller embossing: Bars are passed through rollers with engraved patterns, pressing the pattern onto the surface and creating various designs and textures for aesthetic appeal. 6. Laser texturing: Laser technology removes material from the surface, achieving precise and intricate patterns with high accuracy and repeatability. This method is ideal for decorative purposes or specialized applications that require precise texture control. Each method has its advantages and should be chosen based on the desired texture, application requirements, and cost-effectiveness. Selection depends on factors like intended use, desired appearance, functionality, and budget constraints.

- Q: Can steel flat bars be used for making furniture frames or supports?

- Certainly, furniture frames or supports can indeed be constructed using steel flat bars. Steel, being a versatile and durable material, offers exceptional strength and stability, making it an ideal choice for furniture manufacturing. Steel flat bars provide a solid foundation and structural integrity to furniture frames or supports, guaranteeing durability and stability. Moreover, steel can be easily shaped and welded, allowing for design flexibility and customization. It is commonly employed in the construction of various furniture pieces such as tables, chairs, shelving units, and bed frames. In summary, steel flat bars are a dependable option for furniture frames or supports, offering a robust and enduring solution.

- Q: Do steel flat bars have a specific tolerance range?

- Yes, steel flat bars do have a specific tolerance range. Tolerance refers to the acceptable deviation from the specified dimensions or properties of a product. In the case of steel flat bars, the tolerance range typically includes variations in thickness, width, and length. The specific tolerance range may vary depending on the manufacturing standards, grade of steel, and intended application of the flat bars. These tolerances are important to ensure the flat bars meet the required specifications and can be effectively used in various construction and industrial applications.

- Q: How do steel flat bars perform in corrosive or acidic environments?

- Steel flat bars generally perform well in corrosive or acidic environments, but their resistance to corrosion depends on the type of steel used and the specific properties of the environment. Stainless steel flat bars, for example, are highly resistant to corrosion in most acidic or corrosive environments. This is because they contain a minimum of 10.5% chromium, which creates a protective oxide layer on the surface of the steel that prevents further corrosion. Additionally, stainless steel flat bars can be alloyed with other elements such as nickel or molybdenum to enhance their corrosion resistance even further. However, not all steel flat bars are as resistant to corrosion. Carbon steel flat bars, for instance, are susceptible to rust and corrosion in acidic or corrosive environments. This is because they lack the protective oxide layer present in stainless steel. In such cases, additional measures like galvanization or coating the flat bars with corrosion-resistant materials may be necessary to protect them from corrosion. Overall, it is important to consider the specific type of steel used and the nature of the corrosive or acidic environment when determining the performance of steel flat bars in such conditions. Consulting with experts or referring to corrosion resistance charts can provide more specific information on the suitability of steel flat bars in different environments.

- Q: What is the maximum thickness-to-width ratio for a steel flat bar?

- Several factors, including the specific steel grade, intended usage, and industry standards, influence the maximum thickness-to-width ratio for a steel flat bar. Generally, the maximum ratio is typically 1:10, meaning that the thickness of the flat bar should not surpass 10 times its width. If this ratio is surpassed, it can result in potential problems such as compromised structural integrity, heightened susceptibility to bending or warping, and challenges in fabrication or handling. Therefore, it is crucial to consider the specific application and refer to relevant industry guidelines or standards to determine the appropriate thickness-to-width ratio for a steel flat bar in a given scenario.

- Q: Can steel flat bars be used for making brackets or supports?

- Indeed, brackets or supports can be crafted using steel flat bars. Steel flat bars are renowned for their robustness and longevity, rendering them an exceptional selection for fabricating brackets or supports that must endure substantial loads or offer structural steadiness. Moreover, the flat configuration of the bars facilitates effortless manipulation and attachment to other substances. Furthermore, steel flat bars can be readily welded, drilled, or bent to accommodate specific designs for brackets or supports. In essence, steel flat bars represent a versatile and dependable alternative for fashioning brackets or supports in diverse domains, including construction, manufacturing, or engineering endeavors.

- Q: Can steel flat bars be used for making mining industry equipment?

- Yes, steel flat bars can be used for making mining industry equipment. Steel is a durable and strong material that is commonly used in the mining industry due to its high tensile strength and resistance to wear and tear. Steel flat bars can be fabricated and used for various applications in the mining industry, such as manufacturing conveyor systems, structural supports, and equipment frames.

- Q: Galvanized steel flat welding occurs after the material itself crack.

- Reheat cracking: when welding in the heat affected zone near the fusion County Office is heated to 1200 DEG C, the heat affected zone of grain boundary of vanadium and molybdenum and titanium carbide in austenite when welding; postweld heat treatment of re heating, the heating temperature in the range of 500 degrees to 700 degrees Celsius in the welding, there is a big the welding residual stress in the joints, stress exceeds the plastic heat affected zone near the fusion line of the metal, will produce crack;

- Q: What is the maximum thickness-to-width ratio for steel flat bars?

- The maximum thickness-to-width ratio for steel flat bars can vary depending on the specific grade and type of steel being used. However, in general, the maximum thickness-to-width ratio for steel flat bars is typically around 1:10. This means that the thickness of the bar should not exceed 10 times its width. It is important to note that this ratio may vary based on the specific application and industry standards, so it is always advisable to consult relevant engineering codes and standards to determine the maximum thickness-to-width ratio for a specific steel flat bar.

Send your message to us

Flat Steel high quality slitting hot rolled q235 black carbon steel flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords