Q235B steel flat for construction with good

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Spring Steel can be divided into two types. One is carbon spring steel, and other one is alloy spring steel.

Alloy spring steel is based on carbon spring steel, by adding one or more alloying elements to improve the mechanical properties, hardenability and other properties to meet the requirement for manufacturing all kinds of spring steel.

Specification of Flat Spring Steel:

-Material: 55Si2Mn

-Production: Hot rolled or cold rolled

-Standard: GB/T 1222-1984

-Type: Spring Steel

-Alloy or no: Alloy

Chemical Composition:

C | Si | Mn | S |

0.52~0.6 | 1.500~2.00 | 0.60~0.90 | ≤0.035 |

P | Cr | Ni | Cu |

≤0.035 | ≤0.35 | ≤0.35 | ≤0.25 |

Mechanical Properties:

-Tensile Strength σb (MPa): ≥1274(130)

-Yield Strength σs (MPa): ≥1176(120)

-Elongation δ10(%): ≥6

-Percentage reduction of area: ψ (%): ≥30

-Hardness:

1, Hot rolled, ≤302HB

2, Cold drawn + Heat treatment: ≤321HB

Usage/Applications of Flat Spring Steel:

-Elements Si and Mn improve elasticity strength, hardenability, and the ratio of yield point and tensile strength. but the decarburization tendency is a little large,

-55Si2Mn Spring Steel can be used as vibration damper leaf spring and spiral spring of cars and tractors.

-Heat-resisting spring below 250 degrees.

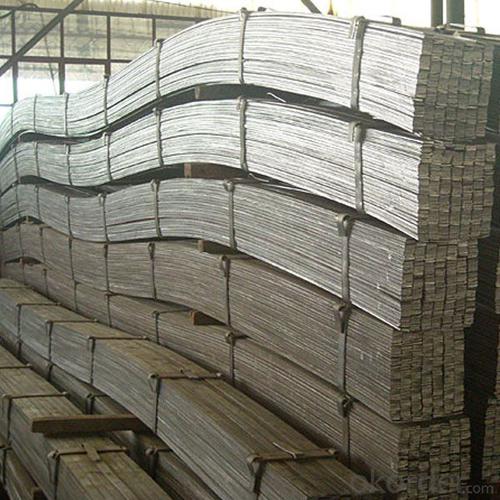

Packaging & Delivery of Flat Spring Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L. 100% payment before shipment.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L. 100% payment before shipment.

3, Negotiable.

- Q: Can steel flat bars be used for making machinery parts or components?

- Indeed, machinery parts or components can be made using steel flat bars. Steel, a versatile and durable material widely utilized in the manufacturing industry, is commonly employed for machinery and equipment. The malleability of steel flat bars allows for easy shaping, cutting, and welding, enabling the creation of various machinery parts and components including brackets, frames, supports, and gears. The superior strength and rigidity of steel make it an excellent choice for machinery applications, capable of withstanding heavy loads, providing stability, and resisting wear and tear. Moreover, steel can be machined and treated to enhance its properties, for instance, through heat treatment or surface coatings, further augmenting its suitability for machinery parts and components.

- Q: How do steel flat bars compare to other types of steel profiles?

- Steel flat bars possess numerous advantages when compared to other types of steel profiles. Firstly, their flat shape renders them highly suitable for applications that prioritize strength and stability, such as construction and manufacturing. The flat surface also facilitates simple attachment and welding, endowing them with versatility and ease of use. In contrast to round bars or square bars, flat bars boast a larger surface area, which contributes to superior load distribution. This quality makes them ideal for scenarios that demand even weight distribution, like bridges or platforms. Moreover, steel flat bars exhibit a consistent thickness throughout their length, unlike other profiles that may feature varying thicknesses. This uniformity guarantees consistent strength and structural integrity, rendering flat bars reliable and predictable in their performance. In addition, steel flat bars frequently prove to be more cost-effective than other profiles due to their simpler manufacturing process. They can be manufactured in large quantities and necessitate less machining, resulting in reduced production costs. This affordability has made them a favored choice across various industries. However, it is essential to note that the selection of a steel profile should be based on the specific requirements of the application. While steel flat bars offer numerous advantages, other profiles may prove more suitable in certain situations. Factors such as load-bearing capacity, aesthetics, and ease of installation should be taken into consideration when determining the most appropriate steel profile for a particular project.

- Q: Can steel flat bars be used for making heat exchangers or cooling systems?

- Heat exchangers or cooling systems can utilize steel flat bars. Steel is widely used and versatile in many industries, including HVAC systems. The advantages of steel flat bars include high strength, durability, and excellent thermal conductivity, which make them suitable for heat transfer applications. In heat exchangers and cooling systems, heat is transferred between fluids or between a fluid and the surrounding environment. To facilitate efficient heat transfer, steel flat bars can be shaped and sized accordingly to form the necessary framework and surfaces. They can be made into fins, tubes, or plates to maximize surface area and enhance heat dissipation. Moreover, steel flat bars can withstand high temperatures and pressures, making them ideal for demanding heat exchange applications. They are also resistant to corrosion, ensuring optimal performance and longevity, especially when exposed to different fluids or environments. However, it is important to consider various factors, such as the specific application, operating conditions, and budget, when choosing materials for heat exchangers or cooling systems. Depending on the requirements, other materials like copper, aluminum, or stainless steel may also be viable options.

- Q: Are steel flat bars suitable for bridges?

- Certainly! Bridges can be constructed using steel flat bars because they possess qualities that make them ideal for this purpose. Steel is a commonly preferred material in bridge construction because it offers a high strength-to-weight ratio, durability, and the ability to withstand heavy loads. Steel flat bars, specifically, provide numerous advantages for the construction of bridges. They offer excellent support and stability, particularly when utilized as structural components or reinforcement in concrete bridge decks. Additionally, steel flat bars can be easily fabricated, cut, and welded to meet the specific design requirements of a bridge. This makes them a versatile choice for bridge construction. Moreover, steel flat bars have a lengthy lifespan and require minimal maintenance, which is crucial for ensuring the bridge's longevity and safety. All in all, steel flat bars are a suitable and extensively used material in bridge construction due to their strength, durability, versatility, and ease of maintenance.

- Q: Can steel flat bars be hardened?

- Yes, steel flat bars can be hardened through a heat treatment process called quenching and tempering. This involves heating the steel to a high temperature and then rapidly cooling it in water or oil, which increases its hardness. The hardened steel can then be further tempered to improve its toughness and reduce brittleness.

- Q: What are the standard tolerances for straightness in steel flat bars?

- The standard tolerances for straightness in steel flat bars vary depending on the specific industry and application. However, in general, the standard tolerances for straightness in steel flat bars are typically defined by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). For example, according to ASTM A6/A6M, which covers general requirements for rolled structural steel bars, plates, shapes, and sheet piling, the maximum deviation from straightness for steel flat bars should not exceed 1/8 inch per 5 feet. This means that for every 5 feet in length, the steel flat bar can deviate from a perfectly straight line by no more than 1/8 inch. ISO 9444-1, which provides the tolerances on dimensions and form for continuously cold-rolled stainless steel narrow strip, also specifies tolerances for straightness. According to this standard, the maximum deviation from straightness for steel flat bars should not exceed 0.2% of the total length. This means that for a 10-foot long steel flat bar, the maximum deviation from straightness should not exceed 0.02 feet or approximately 0.24 inches. It is important to note that these are just a few examples of the standard tolerances for straightness in steel flat bars. Different industries, applications, and specifications may have their own specific tolerances that need to be adhered to. Therefore, it is always recommended to consult the relevant standards or specifications applicable to the specific use case to determine the appropriate tolerances for straightness in steel flat bars.

- Q: Can steel flat bars be used for making furniture?

- Yes, steel flat bars can be used for making furniture. Steel is a versatile and durable material that can be shaped and welded into various furniture designs. Steel flat bars are commonly used to construct furniture pieces such as tables, chairs, shelves, and bed frames. They provide stability, strength, and a modern aesthetic to furniture designs. Additionally, steel can be coated or finished with different colors and textures to match different interior styles. However, it is important to consider the weight and potential sharp edges of steel flat bars when designing and using furniture made from this material.

- Q: Can steel flat bars be cold-formed or bent?

- Indeed, it is possible to cold-form or bend steel flat bars. This process entails shaping the metal at room temperature, without the utilization of heat. To cater to specific applications and designs, steel flat bars are often cold-formed or bent, resulting in various shapes, angles, or curves. Typically, this procedure involves the utilization of specialized machinery like press brakes or rollers to apply force on the steel flat bar, causing it to deform and acquire the desired shape. By cold-forming or bending steel flat bars, precise customization and design flexibility are achieved, rendering them suitable for a broad array of industries and applications, including construction, manufacturing, and engineering.

- Q: What is the minimum order quantity for steel flat bars?

- The minimum order quantity for steel flat bars can vary depending on the supplier or manufacturer. Typically, the minimum order quantity is determined by factors such as production costs, transportation logistics, and customer demand. However, it is common to see minimum order quantities ranging from 1 to 10 metric tons. It is advisable to contact the specific supplier or manufacturer to inquire about their minimum order requirements and negotiate accordingly.

- Q: Can steel flat bars be painted or coated?

- Yes, steel flat bars can be painted or coated.

Send your message to us

Q235B steel flat for construction with good

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords