Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats in Coils are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1.DIN1.2311 flat steel China

2.16-900*185-2300*3000-5800MM or as your requests

3.HRC=28--34

4.Top 10 supplier in Guangdong CN

Round | Diameter | Length | |

20mm-600mm | 2000mm-5800mm | ||

Steel plate | Thickness | Width | Length |

20-400mm | 185-2200mm | 3000mm-5800mm | |

Chinese | American | German | Swedish | Japanese |

GB | AISI | DIN | ASSAB | JIS |

3Cr2Mo | P20 | 1.2311 | 618 | PDS-3 |

Degree of hardness and the metallography structure are even, the cutting value and the polishing performance are outstanding, can be harden by flame, plates hardly chrome and nitriding. This mould steel can apply to general requirements of the size of the plastic mould and can be operated by electric corrosion.

We are direct die steel manufacturer, we can supply kinds of die steel bars with the competitive price and high-quality service, we incerely provide high quality and favorite price, we are looking forward to establish the mutual beneficial and long- term relation with free to contact us for future information!

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

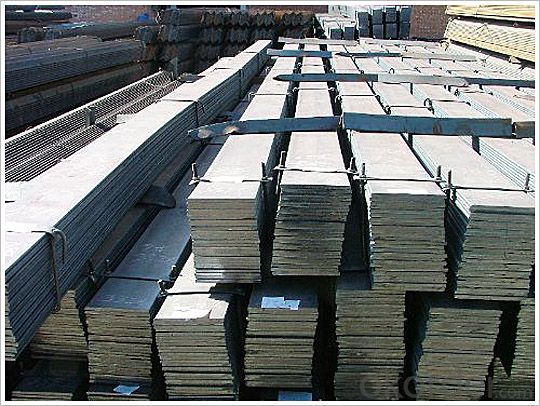

Images:

- Q: Are there any safety considerations when working with steel flat bars?

- Working with steel flat bars involves several safety considerations. To begin with, these bars can be heavy and difficult to handle, so it is important to use correct lifting methods and appropriate equipment to avoid straining or getting injured. Additionally, steel bars may have sharp edges or corners that can cause cuts or punctures. Therefore, it is essential to wear suitable personal protective gear like gloves and safety glasses. Moreover, cutting or shaping steel flat bars can produce sparks and metal fragments, which can create a fire hazard and pose a risk to the eyes. Hence, it is crucial to work in a well-ventilated area and utilize proper eye protection and fire prevention measures. Lastly, welding or other high-temperature processes can make steel flat bars extremely hot, leading to burn injuries. To minimize these risks, it is important to follow correct welding techniques and wear heat-resistant clothing and gloves. Overall, being mindful of these safety considerations and adhering to best practices is vital for the safe handling and manipulation of steel flat bars.

- Q: Can steel flat bars be used in the manufacturing of fencing or gates?

- Yes, steel flat bars can definitely be used in the manufacturing of fencing or gates. Steel flat bars are strong and durable, making them an excellent choice for creating sturdy fences and gates that can withstand various weather conditions and provide security. These bars can be welded or bolted together to form the framework of the fencing or gates, offering stability and durability. Additionally, steel flat bars can be easily shaped and customized to meet specific design requirements, allowing for the creation of unique and visually appealing fences and gates.

- Q: Can steel flat bars be used for making tools or hardware?

- Steel flat bars have the potential to be utilized in the creation of tools and hardware. These bars possess a flexible nature, allowing them to be easily molded and shaped into a variety of tool and hardware components, including wrenches, screwdrivers, chisels, brackets, hinges, and more. They offer robustness, longevity, and resistance against deterioration, making them a fitting choice for demanding tasks. Moreover, steel flat bars can undergo heat treatment to enhance their hardness, ultimately improving their performance as cutting or striking instruments. In summary, due to their dependability and adaptability, steel flat bars are extensively employed in the manufacturing of tools and hardware.

- Q: Are steel flat bars available in different widths?

- Certainly, there is a wide selection of widths for steel flat bars. To cater to diverse application needs, steel flat bars are offered in numerous sizes and dimensions. These widths can vary greatly, starting from as slim as 1/8 inch and extending up to 12 inches or even wider. This wide range of options allows for the flexible utilization of steel flat bars in an array of construction, manufacturing, and fabrication ventures.

- Q: What are the different methods of surface sanding for steel flat bars?

- There are several different methods of surface sanding for steel flat bars. The choice of method depends on the desired finish and the specific requirements of the project. 1. Hand Sanding: This method involves using sandpaper or sanding blocks to manually sand the surface of the steel flat bars. It is a simple and cost-effective method, but it can be time-consuming and may not provide a uniform finish. 2. Belt Sanding: Belt sanding machines use abrasive belts to remove material from the surface of the steel flat bars. They are efficient and can achieve a consistent finish. Belt sanding machines come in different sizes and with various grit options, allowing for customization based on the desired outcome. 3. Disc Sanding: Disc sanding machines utilize rotating sanding discs to remove material from the surface of the steel flat bars. They can be used for heavy material removal or fine finishing, depending on the grit of the sanding discs. Disc sanding machines are available in different sizes and configurations to suit different needs. 4. Random Orbital Sanding: This method involves using a random orbital sander, which combines the spinning action of a disc sander with the random orbit motion of an orbital sander. The sanding discs used with this machine have a random pattern, which helps prevent swirl marks on the surface of the steel flat bars. Random orbital sanders are versatile and can be used for both material removal and fine finishing. 5. Vibratory Sanding: Vibratory sanding machines use vibration to remove material from the surface of the steel flat bars. They are often used for deburring, as well as for achieving a smooth finish. Vibratory sanding machines come in various sizes and can be equipped with different types of media, such as ceramic stones or plastic pellets, depending on the desired outcome. 6. Grinding: Grinding is a more aggressive method of surface sanding that uses a grinding wheel or disc to remove material from the steel flat bars. It is commonly used for heavy material removal, such as removing welds or shaping the steel flat bars. Grinding can be done manually or with the use of grinding machines, depending on the size and complexity of the project. Each method of surface sanding for steel flat bars has its advantages and limitations. The choice of method should be based on factors such as the desired finish, the amount of material to be removed, and the resources available. It is important to consider safety precautions and wear appropriate protective equipment, such as goggles and gloves, when using any of these methods.

- Q: How do you prevent twisting of steel flat bars during welding?

- To avoid the twisting of steel flat bars during welding, there are several precautions that can be taken: 1. Proper preparation is essential. It is important to ensure that the flat bars are thoroughly cleaned and free from any contaminants such as oil, grease, or rust. A wire brush or grinder can be used to remove any impurities on the surface. 2. Securely clamp the flat bars before welding. Sturdy clamps or magnetic welding fixtures can be used to firmly hold the bars in place, preventing any movement or twisting during the welding process. 3. Prior to performing the full weld, temporary tack welds can be used to hold the flat bars together. This will help maintain their alignment and prevent twisting while the final weld is applied. 4. Adopt a strategic weld sequence that minimizes heat distortion and potential twisting. Instead of welding a continuous bead along the entire length of the flat bars, it is recommended to alternate between different sections or weld in short intervals, allowing each area to cool before continuing. 5. Control the heat input during welding by using the appropriate welding technique and adjusting the welding parameters. High heat levels can cause the steel to expand and contract, leading to twisting. Techniques such as pulse welding or reducing the amperage can help control heat input and minimize the risk of twisting. 6. For thicker or more susceptible steel flat bars, preheating the material before welding can help reduce the risk of twisting. Additionally, performing post-weld heat treatment can relieve residual stresses and prevent distortion. 7. Allow the welded flat bars to cool slowly and naturally after welding. Rapid cooling, such as through water quenching, can induce additional stresses and contribute to twisting. It is important to avoid abrupt temperature changes and provide sufficient time for the welded bars to cool down gradually. By implementing these preventive measures, the risk of twisting in steel flat bars during welding can be significantly reduced, ensuring a successful and distortion-free weld.

- Q: Are steel flat bars suitable for food processing or hygiene-sensitive environments?

- No, steel flat bars are not suitable for food processing or hygiene-sensitive environments due to their potential to corrode and contaminate the food or surface they come into contact with.

- Q: Can steel flat bars be used for making aerospace industry equipment or structures?

- Steel flat bars can certainly be used for making aerospace industry equipment or structures. Steel is a widely used material in the aerospace industry due to its high strength, durability, and resistance to extreme temperatures. Flat bars, in particular, are often utilized in aerospace applications for their versatility and ease of use. Steel flat bars can be used to fabricate various components and structures in the aerospace industry, such as frames, supports, brackets, and fittings. These bars can be easily cut, shaped, and welded to meet the specific design requirements of aerospace equipment. Additionally, steel flat bars offer excellent load-bearing capabilities, making them suitable for applications that require high strength and stability. However, it is important to note that the specific type of steel used for aerospace applications must meet stringent quality and performance standards. The aerospace industry often requires materials with exceptional mechanical properties and resistance to corrosion and fatigue. Therefore, steel flat bars used in the aerospace industry must undergo rigorous testing and certification processes to ensure their suitability for these demanding applications. In conclusion, steel flat bars can be effectively used for making aerospace industry equipment or structures. With their strength, versatility, and ease of fabrication, steel flat bars are a valuable choice for various components in the aerospace industry, provided that they meet the required quality and performance standards.

- Q: Are steel flat bars suitable for fabrication of frames or structures?

- Indeed, frames or structures can be fabricated using steel flat bars. Steel, being a robust and long-lasting substance, offers stability and support for diverse applications. These flat bars find widespread use in construction, manufacturing, and engineering ventures. Notably, steel flat bars boast exceptional load-bearing capacity, resistance against bending and warping, and can be effortlessly welded or bolted together to form frames and structures of varying sizes and shapes. Moreover, steel flat bars prove to be economical and easily obtainable in various grades and dimensions, rendering them an adaptable option for fabricating frames or structures.

- Q: Are steel flat bars used in the manufacturing of appliances?

- Yes, steel flat bars are commonly used in the manufacturing of appliances. They are often used as a structural component or for reinforcement purposes due to their strength, durability, and versatility.

Send your message to us

Bulb Flat Steel A,B,D,E,AH32 for Shipbuilding Bulb Flats

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords