Parts For Light Fixtures

Parts For Light Fixtures Related Searches

Lamp Light Fixture Parts Parts For Pendant Lights Wall Light Fixture Parts Replacement Light Fixture Parts Accessories For Lighting Light Fitting Components Ceiling Mount Light Fixture Parts Chandelier Fixture Parts Mini Pendant Light Parts Light Accessories For Cars Industrial Light Fixtures Pendant Light Components Ceiling Light Components Transformer For Light Fixture Halogen Pendant Light Parts Parts of A Ceiling Light Pendant Light Canopy Parts Small Led Light Fixtures Hanging Light Socket Parts Led Replacement Fixtures Ceiling Lamp Parts Led Lighting Accessories Led House Light Fixtures Exterior Light Post Fixtures Stainless Steel Light Fixtures Repair Parts Car Lighting Accessories Large Led Light Fixtures Led Light Bulbs For Ceiling Fixtures Indoor Spotlight FixtureParts For Light Fixtures Supplier & Manufacturer from China

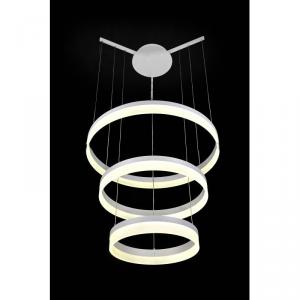

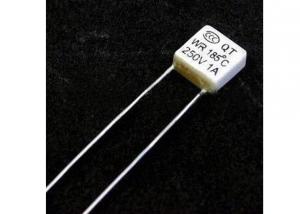

Parts for light fixtures encompass a variety of components that are essential for the proper functioning and aesthetics of lighting systems. These parts include sockets, switches, wiring, bulbs, and various decorative elements that contribute to the overall design and performance of the fixture. They are crucial in ensuring that the light fixtures provide the desired illumination and ambiance in residential, commercial, and industrial settings.Parts for light fixtures are widely used in various applications, such as home improvement projects, office lighting setups, and outdoor lighting installations. They are necessary for maintaining the efficiency and longevity of lighting systems, as well as for enhancing their visual appeal. By replacing or upgrading individual parts, users can customize their lighting fixtures to suit their specific needs and preferences, making them an indispensable resource in the world of lighting solutions.

Okorder.com is a leading wholesale supplier of parts for light fixtures, offering a vast inventory of high-quality products at competitive prices. With a commitment to customer satisfaction, Okorder.com ensures that their customers have access to a diverse range of parts for light fixtures, catering to various lighting needs and styles. By partnering with reputable manufacturers and continuously updating their inventory, Okorder.com has established itself as a reliable source for lighting professionals and enthusiasts alike.

Hot Products