Steel Flat Bar Supply 440C Stainless Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar Supply 440C Stainless Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Supply 440C Stainless Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Supply 440C Stainless Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Commodity: Mild Steel Flat Bar

Standard: GB;JIS

Material: Q195-235;SS400

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

Packaging & Delivery of Hot Rolled Flat Bar Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

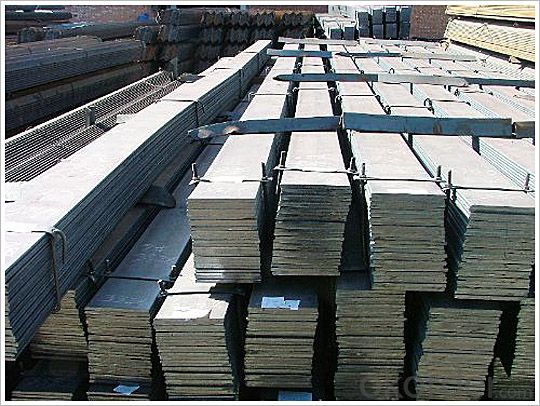

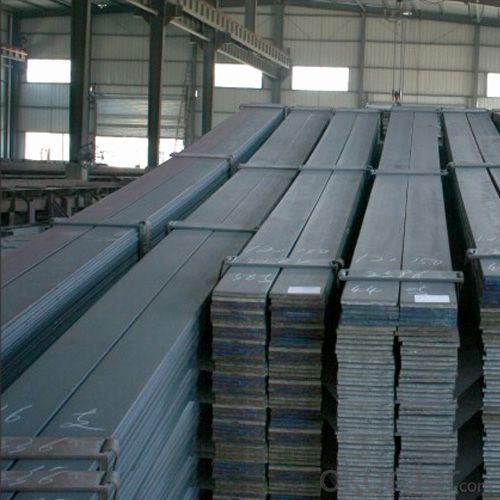

Images:

- Q: Can steel flat bars be used in food processing industries?

- No, steel flat bars are not typically used in food processing industries as they can corrode over time and contaminate the food. Stainless steel is the preferred material due to its corrosion resistance and hygienic properties.

- Q: How do steel flat bars compare in terms of strength and durability?

- Steel flat bars are known for their exceptional strength and durability. Due to their flat shape, they offer enhanced load-bearing capacities and resistance to bending or warping. Additionally, steel flat bars are highly resilient against external impacts and corrosion. Overall, they are a reliable choice for applications requiring robustness and longevity.

- Q: What is the minimum yield strength of a steel flat bar?

- The grade of steel being used determines the minimum yield strength of a steel flat bar. Each grade of steel has its own specific minimum yield strength. Take, for instance, the commonly used grade A36, which boasts a minimum yield strength of 36,000 PSI. Nevertheless, there are stronger grades available, like A572, with a minimum yield strength of 50,000 PSI. To determine the suitable grade and minimum yield strength for a steel flat bar, it is crucial to refer to the specifications and requirements of the particular project or application.

- Q: What are the different methods of surface texturing for steel flat bars?

- There are several different methods of surface texturing for steel flat bars. These methods can be used to impart various textures and patterns onto the surface of the bars, providing aesthetic appeal, improved grip, or enhanced functionality. Some common methods of surface texturing for steel flat bars include: 1. Shot blasting: This method involves propelling small metal or abrasive particles at high velocity onto the surface of the steel flat bars. The impact of these particles creates a textured surface by removing any existing scale, mill scale, or rust, leaving behind a clean and roughened finish. 2. Sanding or grinding: These methods involve using abrasive tools, such as sandpaper or grinding wheels, to manually remove material from the surface of the steel flat bars. This can create a textured finish with patterns or grooves, depending on the technique used. 3. Knurling: Knurling is a process where a pattern of ridges or grooves is rolled or pressed onto the surface of the steel flat bars. This method is often used to improve grip and prevent slipping, making it suitable for applications where a non-slip surface is required. 4. Acid etching: Acid etching involves using chemical solutions to selectively remove a thin layer of the steel's surface, creating a textured pattern. This method allows for precise control over the texture and can produce intricate designs or logos on the steel flat bars. 5. Roller embossing: In this method, the steel flat bars are passed through a set of rollers with engraved patterns. As the bars pass through the rollers, the pattern is pressed onto the surface, creating a textured finish. Roller embossing can be used to create various designs and textures, providing an aesthetic appeal to the steel flat bars. 6. Laser texturing: Laser technology can be used to create precise and intricate patterns on the surface of steel flat bars. By using a laser beam to remove material from the surface, a textured finish can be achieved with high accuracy and repeatability. This method is often used for decorative purposes or for specialized applications where precise texture control is required. Each of these methods offers its unique advantages and can be chosen based on the desired texture, application requirements, and cost-effectiveness. The selection of the appropriate surface texturing method for steel flat bars depends on factors such as the intended use, desired appearance, functionality, and budget constraints.

- Q: Can steel flat bars be used for making brackets or supports for agricultural machinery?

- Indeed, brackets or supports for agricultural machinery can be fashioned using steel flat bars. Renowned for their robustness and endurance, steel flat bars are well-suited for demanding tasks within the agricultural sector. They can be effortlessly shaped or joined through welding to fabricate personalized brackets or supports capable of enduring the rigorous circumstances and substantial burdens frequently encountered in agricultural machinery. What's more, steel flat bars are conveniently obtainable in diverse dimensions, enabling adaptability in both design and application.

- Q: Is there a requirement for the ground resistance of the field motor? Is it good to use ground flat steel or ground wire?

- The grounding steel is better, the resistance is small, and the wiring is convenient, and the grounding is flat steel.

- Q: Can steel flat bars be used for manufacturing industrial machinery or equipment?

- Indeed, the utilization of steel flat bars in the production of industrial machinery or equipment is viable. Steel, being a material that is both adaptable and enduring, is frequently employed within the manufacturing sector due to its exceptional robustness and capacity to withstand substantial loads and harsh conditions. Particularly, steel flat bars are highly favored due to their level surface, which renders them suitable for a multitude of purposes including cutting, welding, and shaping into various machine components or parts. Moreover, the fabrication of steel flat bars is easily accomplished, allowing for flexibility in design and customization. In summary, steel flat bars represent a dependable selection when it comes to the manufacturing of industrial machinery and equipment, ensuring the essential strength and stability required for such applications.

- Q: Can steel flat bars be used for making shelving units?

- Yes, steel flat bars can definitely be used for making shelving units. Steel flat bars are strong and durable, making them an excellent choice for shelving units that need to support heavy items. They can be easily cut and welded to create the desired size and shape of the shelving unit. Steel flat bars also have a sleek and modern look, making them suitable for various styles of interiors. Additionally, steel is resistant to corrosion, which ensures that the shelving units will last for a long time without rusting or deteriorating. Overall, steel flat bars are a reliable and versatile material for constructing sturdy and functional shelving units.

- Q: What are the different coatings available for steel flat bars?

- Steel flat bars have various coating options available depending on the desired properties and specific application. Some commonly used coatings include: 1. Hot-dip galvanizing: The steel flat bar is immersed in molten zinc, creating a protective layer that offers excellent corrosion resistance and can withstand harsh environments. 2. Powder coating: A dry powder is applied to the steel flat bar and then heated to create a durable, chip-resistant protective layer. Powder coating comes in a wide range of colors. 3. Epoxy coating: Industrial settings often use epoxy coatings for corrosion protection. These coatings are applied as a two-part system and offer excellent chemical resistance and durability. 4. Paint: Steel flat bars can be painted with different types of paints, such as oil-based, acrylic, or epoxy paints. Paint coatings provide some level of corrosion protection and can be customized with various colors and finishes. 5. Vinyl coating: Vinyl coatings are commonly used for aesthetic purposes or to create a soft, non-slip surface. These coatings are applied by heat shrinking a vinyl sleeve onto the steel flat bar. When selecting the appropriate coating for steel flat bars, it is important to consider specific requirements, such as corrosion resistance, environmental factors, and aesthetic preferences. Consulting with a professional or coating manufacturer can help determine the best coating option for a particular project.

- Q: Can steel flat bars be used for making stairs or handrails?

- Yes, steel flat bars can be used for making stairs or handrails. They are commonly used in construction and fabrication due to their strength and durability. Steel flat bars provide a sturdy and reliable option for creating stable and secure stairs or handrails.

Send your message to us

Steel Flat Bar Supply 440C Stainless Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords