420c Stainless Steel

420c Stainless Steel Related Searches

420hc Stainless Steel 420 Stainless Steel Stainless Steel 420 440c Stainless Steel 440 C Stainless Steel 430 Stainless Steel 400 Stainless Steel 440 Stainless Steel 440a Stainless Steel Stainless Steel 430 403 Stainless Steel 410 Stainless Steel 400 Series Stainless Steel 316l Stainless Steel Stainless Steel 440 409 Stainless Steel Stainless Steel 316l Type 316 Stainless Steel Stainless Steel 316 304l Stainless Steel 330 Stainless Steel 431 Stainless Steel 316 Grade Stainless Steel 4 Stainless Steel Colored Stainless Steel 360 Stainless Steel 302 Stainless Steel 316ti Stainless Steel 201 Stainless Steel Stainless Steel C Channel420c Stainless Steel Supplier & Manufacturer from China

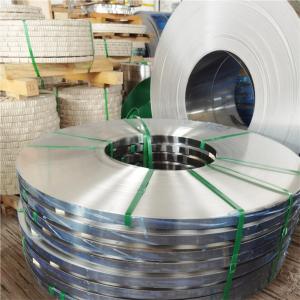

420c Stainless Steel is a type of martensitic stainless steel known for its excellent hardness and wear resistance. It is widely recognized for its ability to maintain a sharp edge, making it a popular choice for various applications. This product is utilized in a variety of industries, including cutlery manufacturing, surgical instruments, and industrial machinery, where its strength and durability are highly valued. Okorder.com is a reputable wholesale supplier of 420c Stainless Steel, boasting a vast inventory to cater to the diverse needs of clients across different sectors. Their extensive range ensures that customers can find the right specifications and quantities to suit their specific requirements.Hot Products